Rod force sensor with simplified adjustment

A technology of force sensor and strain sensor, which is applied in the field of rod-shaped force sensor, can solve problems such as cost and achieve high measurement accuracy and high linearity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

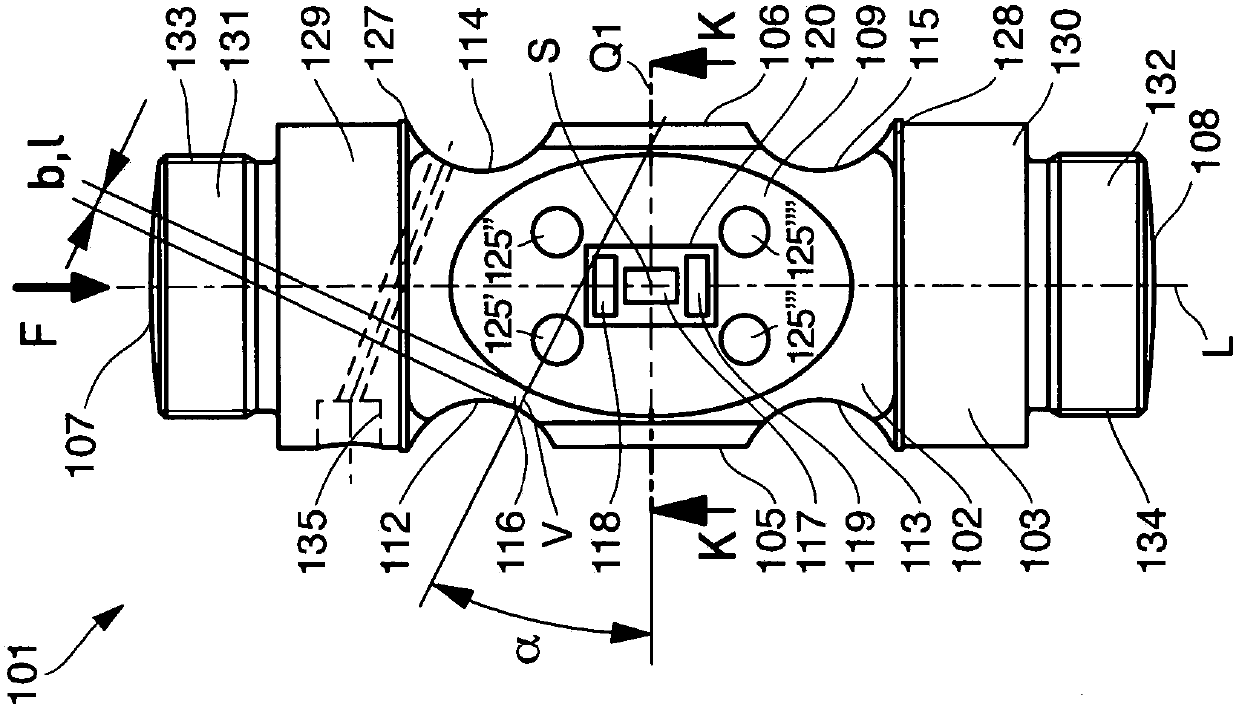

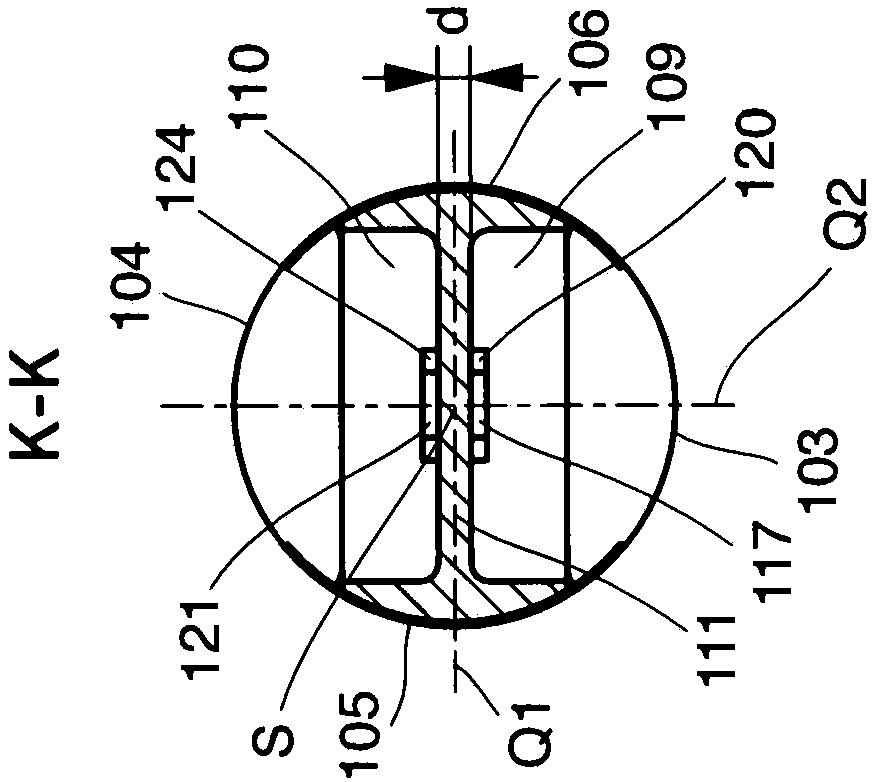

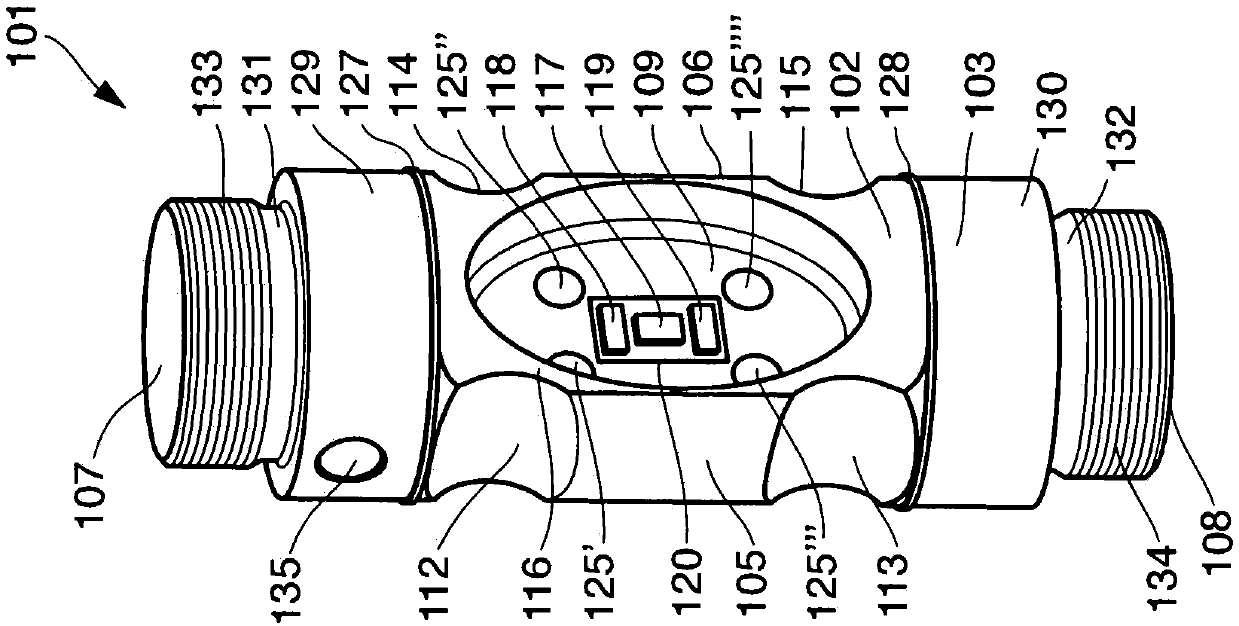

[0042] Figure 1a shows a front view of the force sensor 101 according to the first embodiment, Figure 1b Section K-K of force sensor 101 is shown, Figure 1c A perspective view of force sensor 101 is shown.

[0043] The force sensor 101 comprises a rod-shaped deformation body 102 made of a material such as steel, titanium, aluminum or beryllium copper. The rod-shaped deformation body can be machined from a rod with a circular, square or other cross-section, for example from a piece of round or rectangular steel. The following description proceeds from the fact that the deformation body is based on a cylindrical rod and itself has a cylindrical basic shape as shown in the illustration. However, other variants are also possible, in which the deformation body 102 can also have more sides than those described below.

[0044] The deformation body 102 has a central longitudinal axis L which is at Figure 1a extends vertically in the front view shown in . The deformation body a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com