Multifunctional lifter apparatus

A multi-functional, hanging piece technology, applied in the field of spreaders, can solve the problems of a lot of time and materials, waste, low spraying speed, etc., and achieve the effect of increasing the speed, increasing the spraying quantity, and uniform feeding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

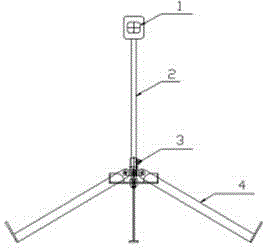

Image

Examples

Embodiment Construction

[0009] The present invention will be further explained below in conjunction with the accompanying drawings.

[0010] A multifunctional lifting device, characterized in that it includes a hanging piece 1, a round steel 2, a fixing seat 3, a hook piece 4, a limit seat 5, and a screw 6, and the round steel top 2 is terminated with a hanging piece 1 , the bottom of the round steel 2 is welded with a screw 6, the round steel 2 is covered with a fixed seat 3, and the fixed seat 3 is provided with a slip ring, wherein the hook piece 4 is set on the round steel 2 through the fixed seat 3; the limit seat 5 It is fixedly connected to the bottom of the round steel 2, and the two ends of the spacer seat 5 are provided with a spacer hole 7, and the spacer hole 7 is sleeved on the hook plate 4.

[0011] The present invention operates the hook piece 4 through the fixing seat 3 and the limiting seat 5, so that when the fixing seat 3 moves upwards along the round steel 2, the hooking pie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com