Closing device for sealing head and closing method

A technology of closing device and head, which is applied to other household appliances, household appliances, applications, etc., can solve the problems of difficult closing dimensional accuracy, scrapped head, insufficient rigidity, etc., to avoid height inconsistency, avoid serious camber, The effect of reducing the scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

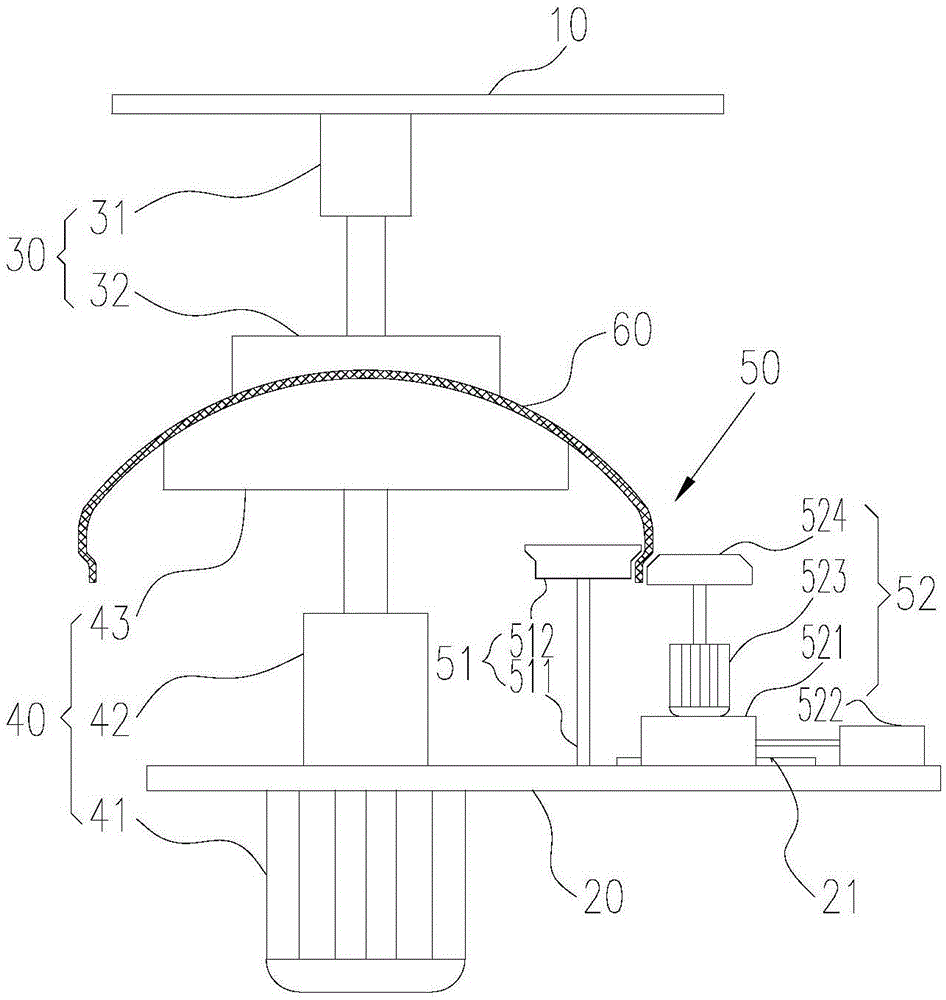

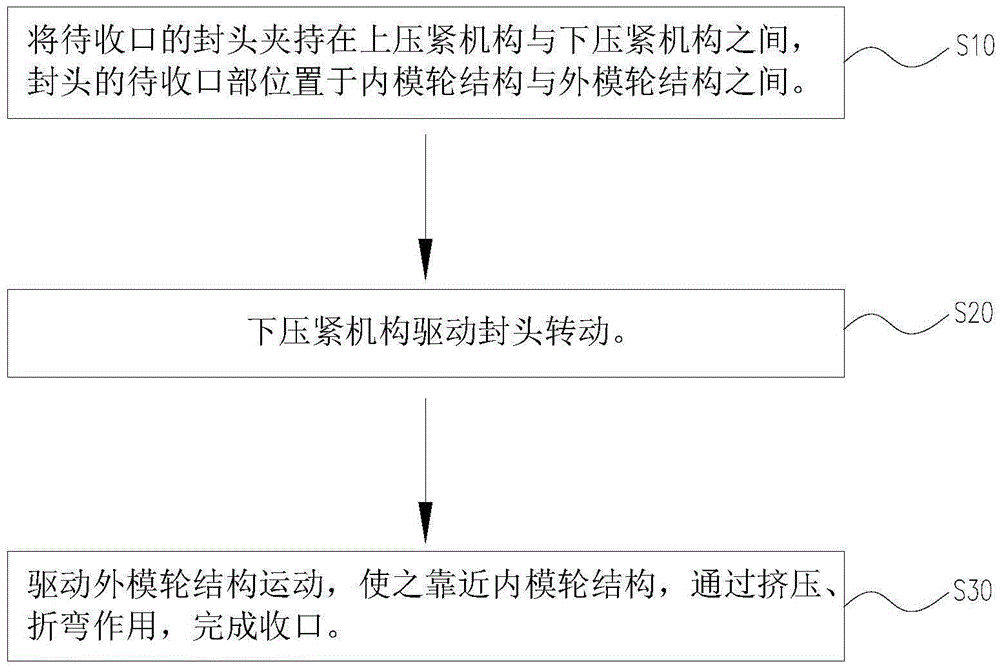

[0024] refer to figure 1 As shown, the present invention provides a closure device for closing the closure head 60. The closure device includes a top plate 10 and a bottom plate 20 arranged oppositely, an upper pressing mechanism 30 arranged on the top plate 10, and a The lower pressing mechanism 40 and the closing mechanism 50 on the base plate 20.

[0025] The upper pressing mechanism 30 includes an upper pressing oil cylinder 31 installed on the top plate 10 and an upper pressing member 32 arranged at the output end of the upper pressing oil cylinder 31, and the cylinder end of the upper pressing oil cylinder 31 is rotatably mounted on On the top plate 10 , the upper pressing member 32 is fixedly arranged on the output end of the upper pressing oil cylinder 31 , and the upper pressing member 32 is driven to rotate by the rotation of the upper pressing oil cylinder 31 .

[0026] The lower pressing mechanism 40 includes a first motor 41 fixedly installed on the base plate 20...

Embodiment 2

[0040] The difference between this embodiment and Embodiment 1 is that: the end of the cylinder body of the upper pressing cylinder 31 is fixed on the top plate 10, and the upper pressing member 32 is rotatably installed on the output end of the upper pressing oil cylinder 31 . Driven by the lower pressing mechanism 40, the upper pressing member 32 at the output end of the upper compression oil cylinder 31 is driven to rotate.

[0041] A closing device for a head of the present invention, compared with a traditional closing device, fixes the closing head 60 between the upper pressing mechanism 30 and the lower pressing mechanism 40, so that the end to be closed of the closing head 60 is only subjected to external pressure. The extrusion force of the mold wheel 524 eliminates the support force in the vertical direction and avoids the severe outward tilt of the closing part. At the same time, it also avoids the situation that the height of the closing part is inconsistent due to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com