Numerical control gear hobbing control method for gear repairing

A control method and gear technology, applied to components with teeth, belts/chains/gears, gear teeth, etc., can solve problems such as difficult to improve machining accuracy, reduce costs, and difficult to reposition hobbing, to achieve precision and surface Effects of low roughness, cost reduction, and productivity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples.

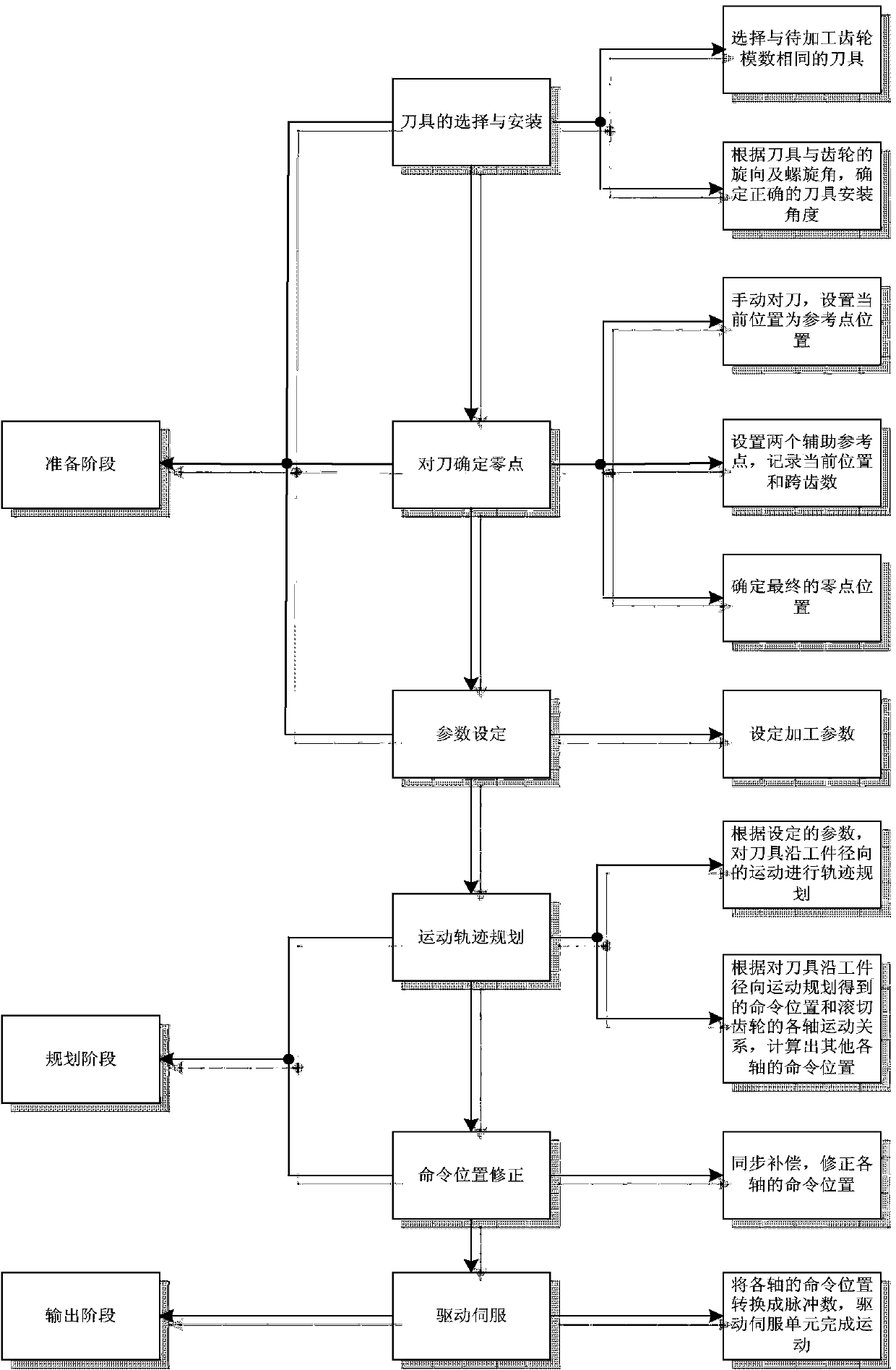

[0037] figure 1 Generally, the control process of the present invention is summarized.

[0038] The gear repair control process can be roughly divided into three stages: preparation stage, planning stage, and output stage. The three stages are described in detail below, and the entire gear restoration control process is elaborated in detail.

[0039] ①Preparation stage

[0040] This stage mainly completes the preparatory work before trajectory planning.

[0041] After the gear to be repaired is determined, the modulus of the selected tool is determined accordingly. Select the hob with the same modulus as the gear to be repaired, and adjust the installation angle of the cutter according to the direction of rotation and helix angle of the cutter and gear.

[0042] After the tool installation angle is determined, each axis of the system returns...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com