Clamping process of middle disc for explosion-proof motor

A technology of explosion-proof motors and intermediate discs, which is applied in metal processing equipment, metal processing machinery parts, clamping, etc., can solve the problems that traditional processes are difficult to realize, affect safe production, and the clamping point of machine tools is small, so as to eliminate milling chatter , Improve production efficiency and high pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

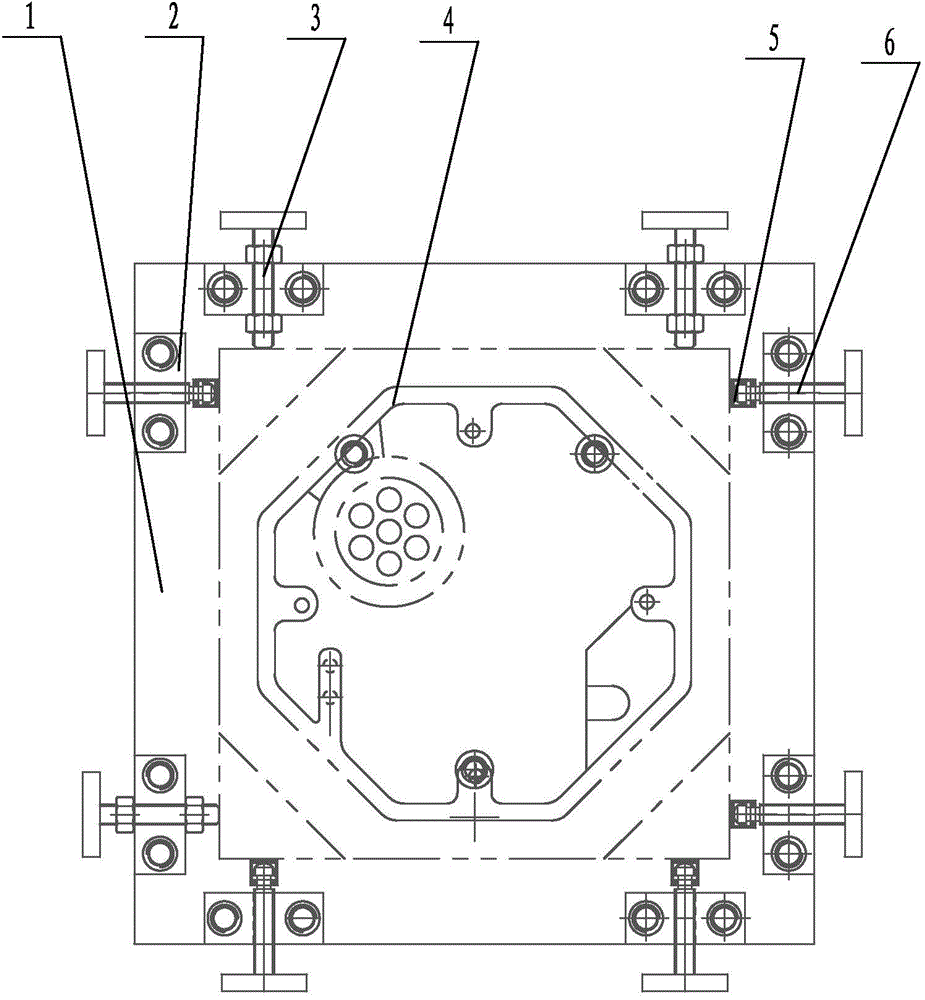

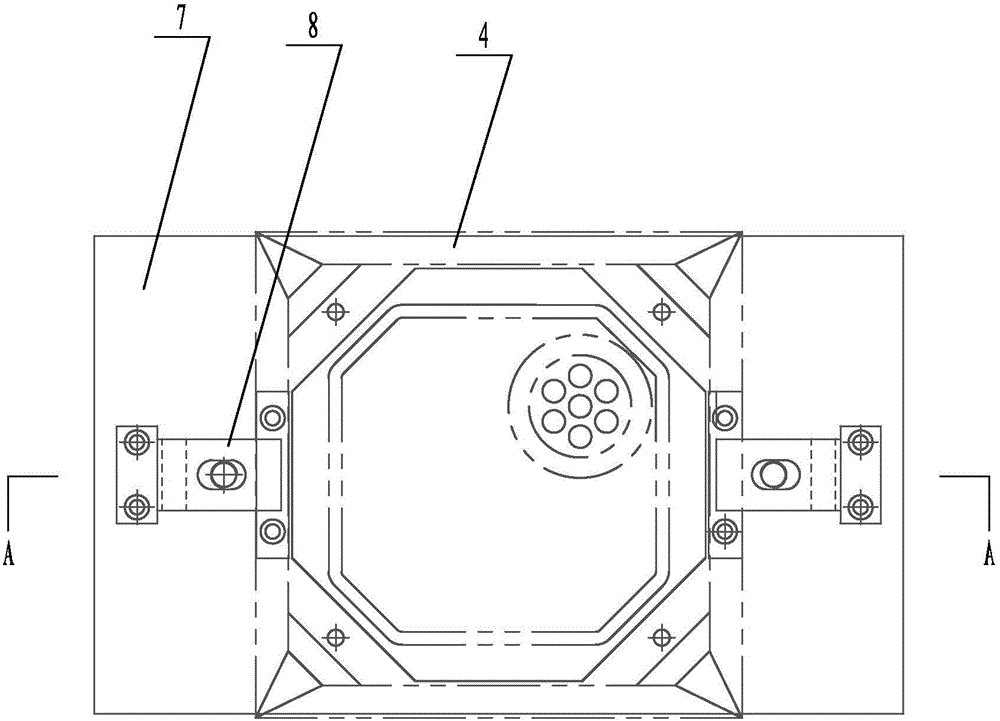

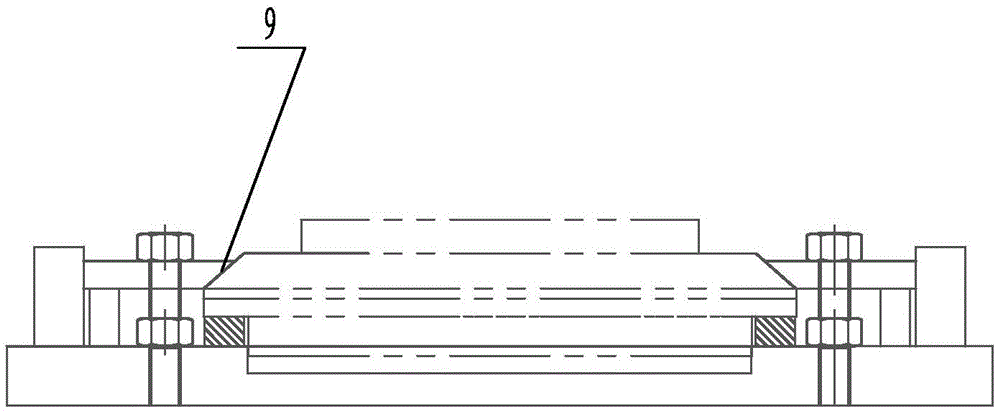

[0021] Such as Figure 1-Figure 3 As shown, the explosion-proof motor intermediate disc clamp of the present invention includes a front clamp and a rear clamp,

[0022] The front fixture includes a front fixture plate 1 and a nut seat 2 fixed on the front fixture plate 1. The nut seat 2 is distributed in the circumferential direction to form a clamping area. The screw holes of the nut seat 2 are fitted with positioning bolts 3 and adjustment bolts 6 to position The clamping end of the bolt 3 and the adjusting bolt 6 faces the clamping area, and the positioning bolt 3 is fixed on the nut seat 2 through a nut,

[0023] The rear clamp includes a rear clamp disc 7, and the bottom of the rear clamp disc 7 is symmetrically provided with a clamping piece 8, and the clamping piece 8 is fixed on the rear clamp disc 7 by bolts.

[0024] The clamping end of the adjusting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com