Grinding head type guide surface processing tool

A guide rail surface and grinding head technology, applied in the field of machinery, can solve the problems of low machining accuracy, large scraping amount, and high labor intensity, and achieve the effects of convenient operation, reducing scraping amount and labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

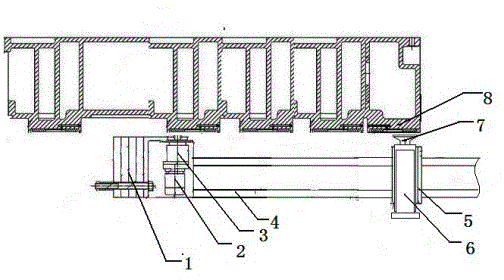

[0013] This embodiment provides a grinding head type guide rail surface processing tool, which is characterized in that: the grinding head type guide rail surface processing tool includes a counterweight (1), a motor (2), a reducer (3), a slideway (4), slider (5), lifting device (6), electric grinding head (7), guide rail surface (8);

[0014] Among them: the motor (2) is connected with the reducer (3) and installed on the fixed seat at one end of the slideway (4), the slider (5) is connected with the motor (2) line, and the slider (5) is equipped with a lift Device (6), the electric grinding head (7) is installed on the upper end of the lifting device (6), and the upper end of the electric grinding head (7) contacts with the guide rail surface (8).

[0015] The crossbeam is installed on the leftmost side of the slideway (4), and the counterweight (1) is installed on the crossbeam to play the role of counterweight.

[0016] The lifting device (6) is a lifting oil cylinder.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap