Method for preparing carbon fiber reinforced thermoplastic prepreg by dusting technology

A technology for reinforcing thermoplastic and carbon fibers, which is applied in the field of design and preparation of composite material intermediates, and achieves the effects of simple preparation method, stable performance and satisfying product requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

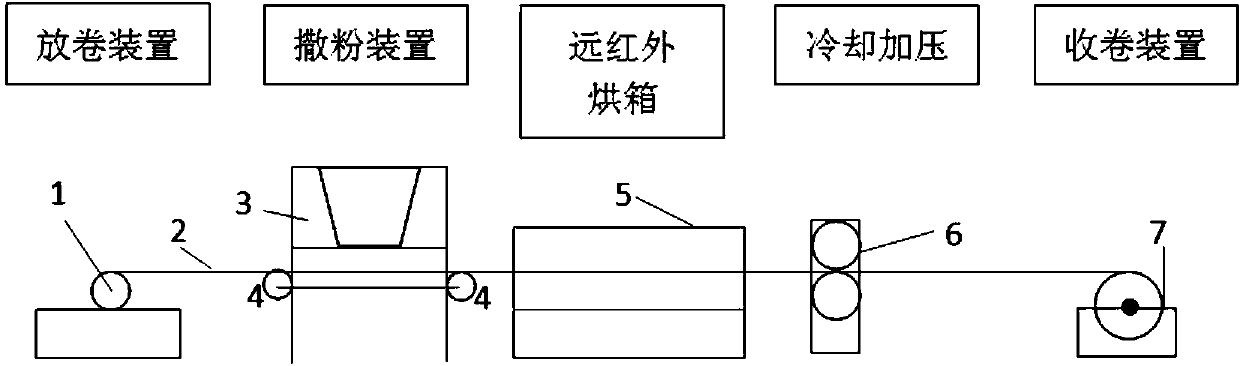

[0029] Such as figure 1 As shown, the pre-processed carbon fiber unidirectional carbon cloth 2 with a width of 400mm is fixed on the unwinding device 1, and then advances forward at a speed of 1m / min through the carbon cloth conductive roller 4, and at the powder spreading device 3, PA6 resin is evenly sprinkled on the upper surface of the carbon cloth. Within 1 minute, the weight of the resin falling on the carbon cloth with an area of 400mm×400mm is 48g, and the dusting time is 0.4min. Infrared oven 5, set the heating temperature in the far-infrared oven 5 to 240°C, so that the PA6 resin is fully melted and impregnated with carbon fibers at this temperature. After leaving the far-infrared oven 5, the carbon fiber unidirectional carbon cloth 2 enters the cooling roller 6, and the resin After cooling and flattening, a carbon fiber reinforced thermoplastic prepreg is formed, and finally the prepreg is rolled and formed by the winding device 7, and the obtained carbon fiber re...

Embodiment 2

[0031] Such as figure 1 As shown, the pre-processed carbon fiber unidirectional carbon cloth 2 with a width of 400mm is fixed on the unwinding device 1, and then advances forward at a speed of 1m / min through the carbon cloth conductive roller 4, and at the powder spreading device 3, PA12 resin is evenly sprinkled on the upper surface of the carbon cloth. Within 1 minute, the weight of the resin falling on the carbon cloth with an area of 400mm×400mm is 48g, and the dusting time is 0.4min. Infrared oven 5, set the heating temperature in the far-infrared oven 5 to 200°C, so that the PA12 resin is fully melted and impregnated with carbon fibers at this temperature. After leaving the far-infrared oven 5, the carbon fiber unidirectional carbon cloth 2 enters the cooling roller 6, and the resin After being cooled and flattened, a carbon fiber reinforced thermoplastic prepreg is formed, and finally the prepreg is rolled and formed by the winding device 7 . The resulting prepregs a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com