Filling machine capable of automatically counting pills

A filling machine and automatic technology, which is applied in the directions of automatic packaging control, packaging, packaging protection, etc., can solve the problems of difficulty in ensuring the cleanliness of pills, unqualified rate of pills, low reliability, etc. Simple, high-quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

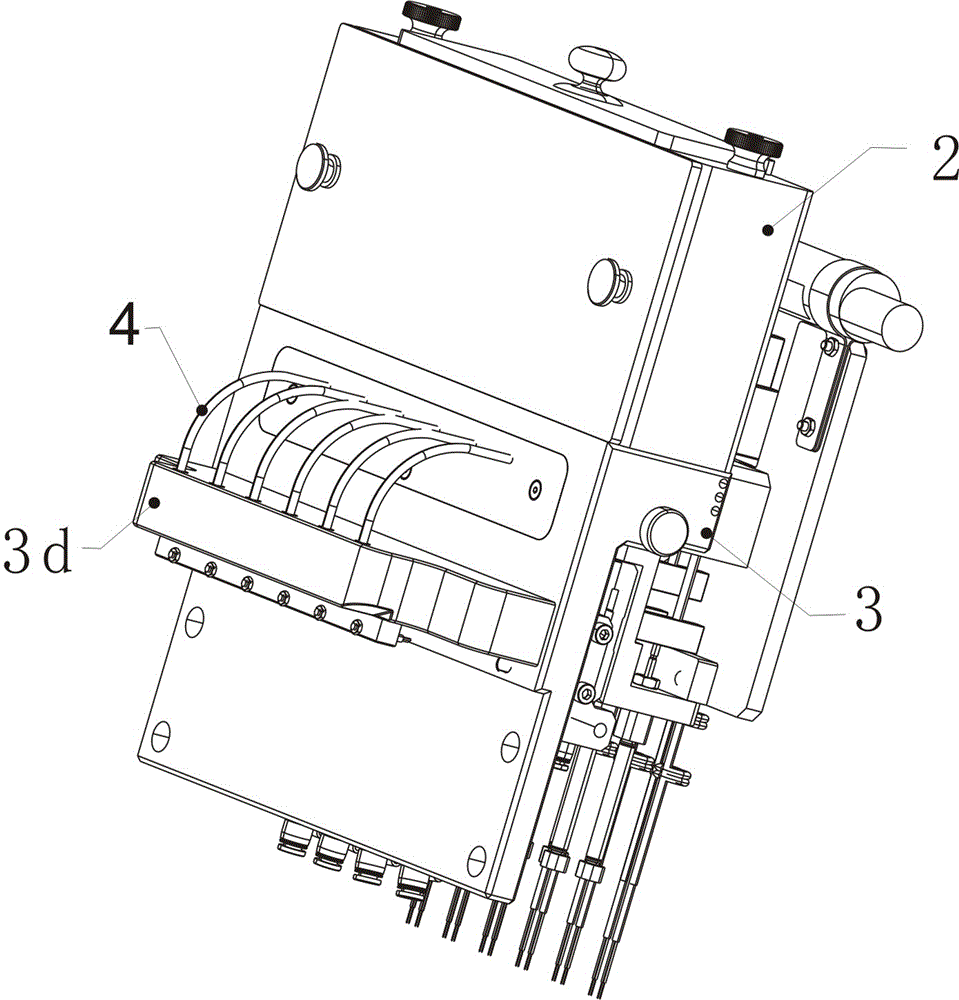

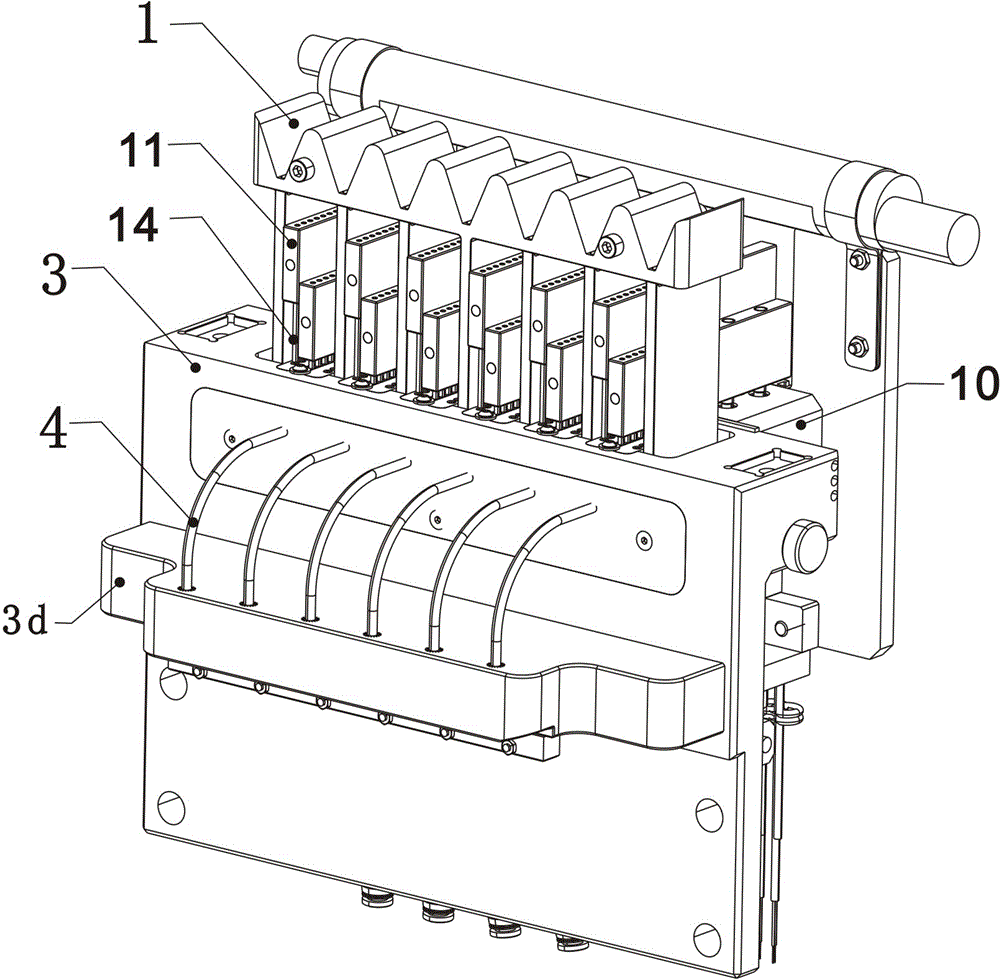

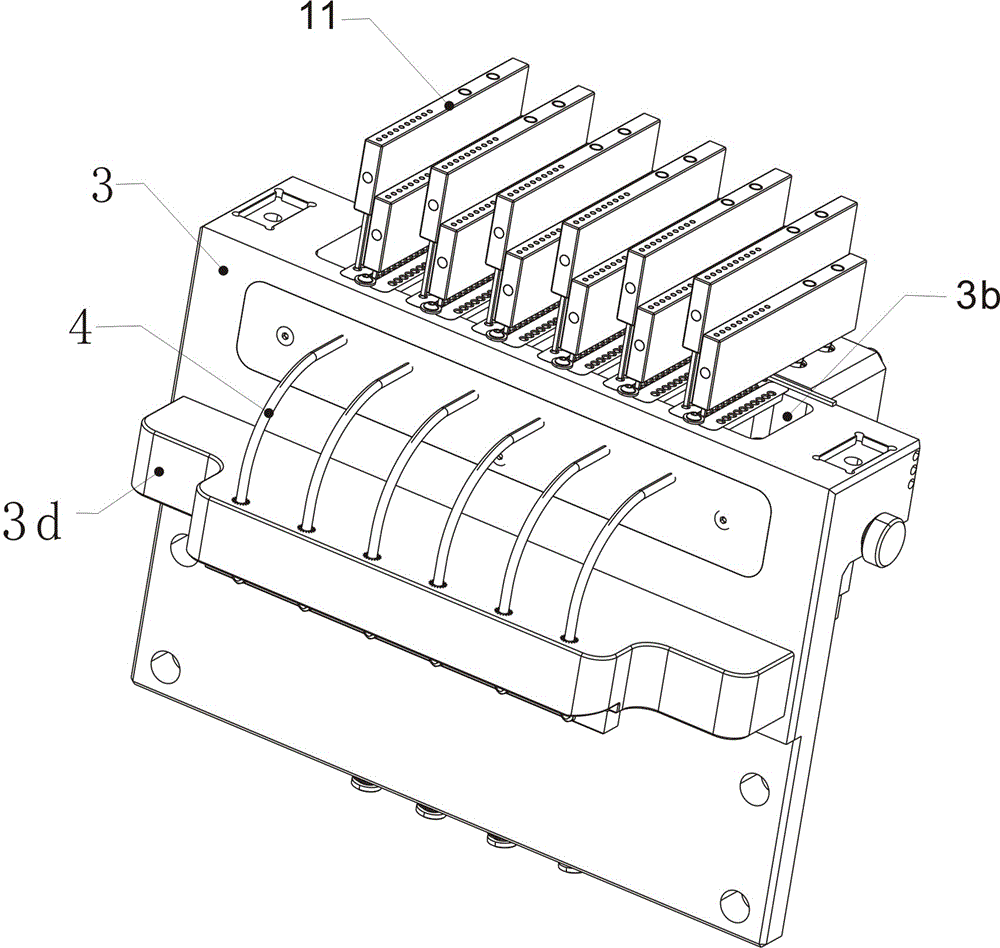

[0038] Embodiment 1: as Figure 1-12 As shown, the present invention provides a kind of automatic counting and filling machine for micropills, including a medicine hopper 1, a medicine blowing part 3, a medicine outlet pipe 4, a moving part 6, a cylinder and a suction pipe mounting part 11; the medicine hopper 1 The support frame 2 is installed on the top of the medicine blowing part 3, and the medicine blowing part 3 is provided with a medicine outlet pipe 4; the suction pipe mounting part 11 is equipped with a suction pipe 14, and there are multiple groups of suction pipe mounting parts 11, and they are installed on the linear guide rail On the linear guide rail in the fixed frame 10, and between the medicine hopper 1 and the medicine blowing part 3, a three-way electromagnetic reversing valve that can blow and inhale is connected through the air pipe at the rear end of the suction pipe mounting part 11; The guide rail is connected with the telescopic rod 5; the linear guide...

Embodiment 2

[0040] Embodiment two: as Figure 1-3 As shown: put the pills into the left and right drug tanks 1a of the medicine blowing part 1, ready for use; the main air valve is controlled through the program control operation platform, and the pipes connected from the main air valve are respectively connected to the cylinder, and the medicine blowing part 3, The suction pipe mounting part 11 and the telescopic rod 5; by controlling the operating platform, the suction pipe mounting part 11 is controlled to move up and down to realize the suction pipe 14 moving up and down, and at the same time, the cylinder controls the moving part 6 to slide left and right, thereby driving the suction pipe mounting part 11 to move left and right; When the part 11 moves left and right and moves up and down, after the suction pipe 14 absorbs the medicine, it moves upwards, and then moves left and right to put the suction pipe 14 in the suction pipe groove 3c, so as to realize the blowing out of the pills...

Embodiment 3

[0042] Embodiment three: as figure 1 As shown; a total of two groups of suction pipe mounting parts 11, a suction pipe 14 is installed below the mounting parts, and both groups of suction pipe mounting parts 11 are equipped with a medicine outlet 3a; the size of the medicine outlet 3a matches the number of suction pipe mounting parts 11; The suction pipe groove 3c arranged in the middle of the medicine piece 3, and the number of the suction pipe groove 3c matches the number of the suction pipes 14 on each group of suction pipe mounting parts 11;

[0043] Such as Figure 4 The two groups of suction pipe mounting parts 11 can be designed as a group, and the suction pipe mounting parts 11 can be used as a group when necessary. At this time, only one group of suction pipe mounting parts 11 is needed to complete the process of inhaling and blowing medicine. When necessary, the suction tube installation part 11 can be used as multiple groups, such as 3 groups, 4 groups, etc., and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com