Gypsum plaster board, preparation method and use method thereof

A paper-faced gypsum board and gypsum technology, which is applied to other household appliances, chemical instruments and methods, applications, etc., can solve problems such as dirt, poor overall appearance, and limited use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The application also provides a preparation method for the perforated gypsum board, which includes the following steps:

[0046]A preparation method for perforated gypsum board, comprising the following steps:

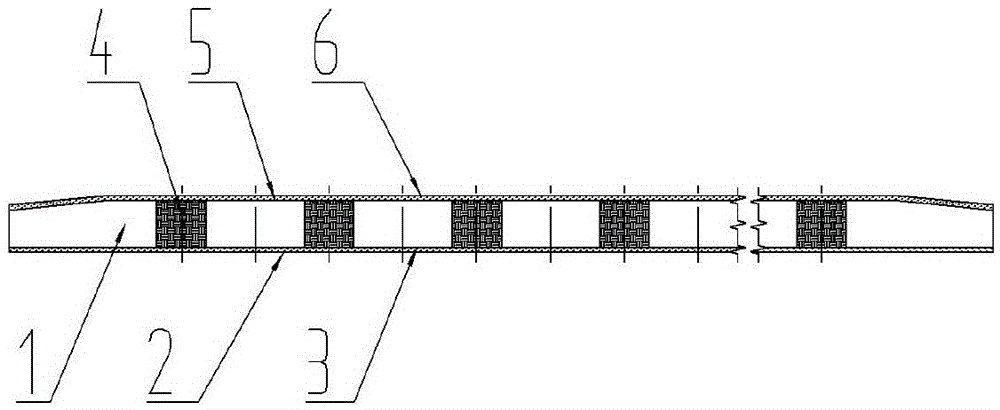

[0047] A), perforate in the direction perpendicular to the plasterboard;

[0048] B), the upper surface and the lower surface of the gypsum board obtained in step A) are respectively laid with the first face paper and the second face paper, and the mixed powder formed by the following components is sprayed on the first face paper : 40wt% ~ 55wt% diatom ooze, 1 ~ 3g / kg nano TiO 2 / Diatomite composite photocatalytic material and 3-4g / kg hydrogen-containing silicone oil;

[0049] Spray gypsum-based diatom mud on the surface of the hole, and the gypsum-based diatom mud includes nano-TiO 2 / Diatomite composite photocatalytic material;

[0050] Lay a sticking film on the surface of the second face-protecting paper.

[0051] In the process of preparing the perfora...

Embodiment 1

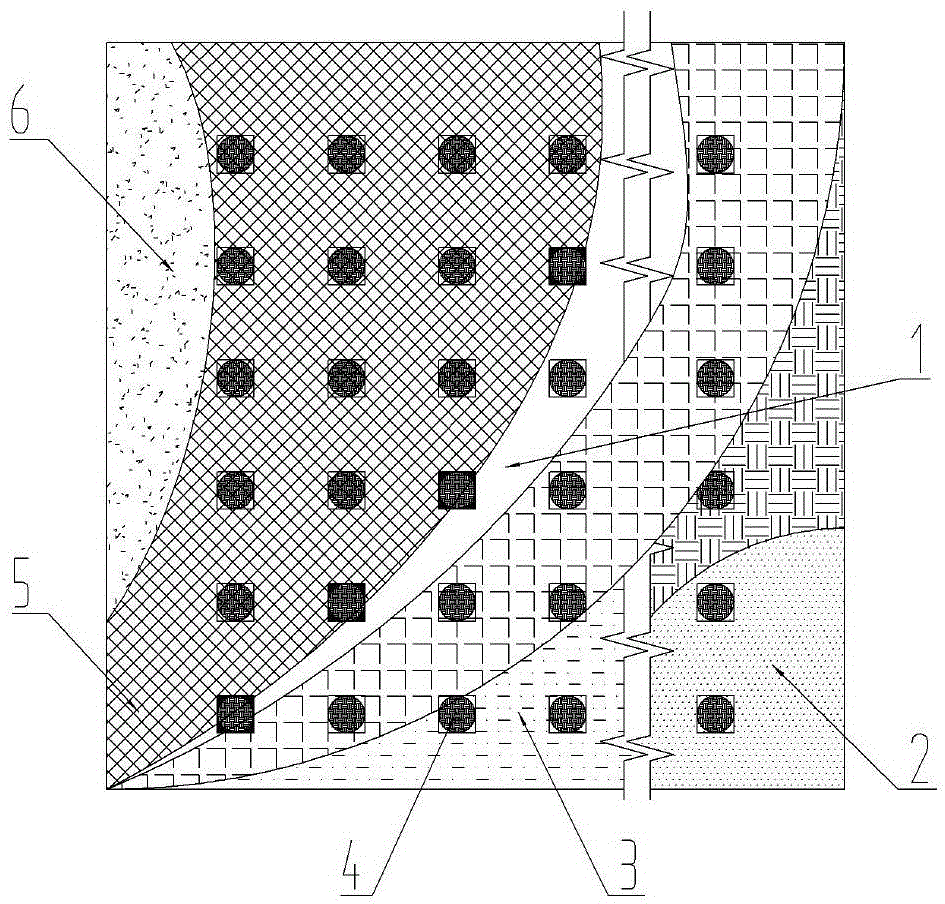

[0063] Perforate the base gypsum board with a size of 600×600mm and a thickness of 9mm, lay a protective paper on the upper surface of the paper-faced gypsum board, lay a water-resistant protective paper on the lower surface, and spray the following components on the surface of the water-resistant protective paper. Mixed powder (the diatom ooze of 45wt%, the nanometer TiO of 3g / kg 2 / diatomite composite photocatalytic material, 4g / kg hydrogen-containing silicone oil, 45wt% hemihydrate gypsum, 10wt% lime and 30g / kg inorganic pigment), spray twice to form a 3mm thick finish layer, In-pore spraying of gypsum board containing 3wt‰ nano-TiO 2 The diatom ooze of / diatomite composite photocatalytic material is laid on the surface of the protective paper, and the film is a film obtained by a two-way PET stretched corona film through surface aluminization, forming such as Figure 7 The perforated plasterboard.

Embodiment 2

[0065] The same as the preparation method of Example 1, the difference is: the raw materials in the finishing layer include: 52wt% diatom ooze, 1g / kg nano TiO 2 / diatomite composite photocatalytic material, 3.5g / kg hydrogen-containing silicone oil, 41wt% hemihydrate gypsum, 7wt% lime and 20g / kg inorganic pigment. The formaldehyde decomposition rate of the perforated gypsum board obtained in this example can reach 75-80% after being exposed to light for 72 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com