Starter overload protection structure

An overload protection and starter technology, which is applied to engine components, engine starting, machine/engine, etc., can solve the problems of high temperature melting of the external circuit of the vehicle or the starter, and vehicle fire, so as to reduce the burning phenomenon and reduce the ablation. , to avoid the effect of ablation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

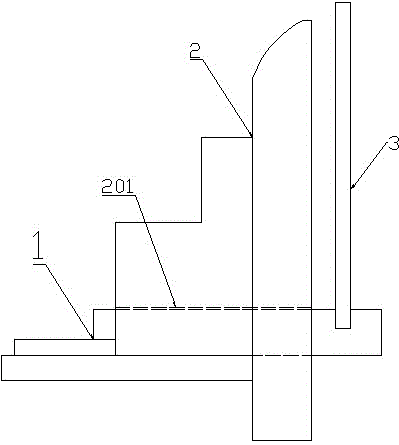

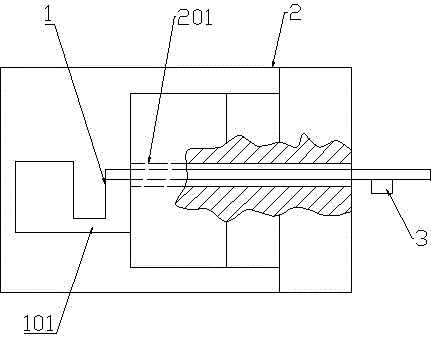

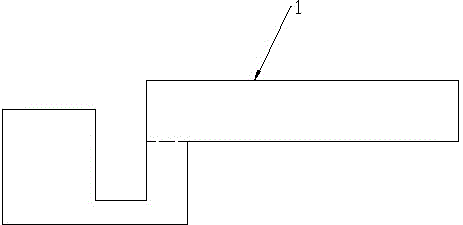

[0011] As shown in the figure, the starter overload protection structure includes a sheath 2, and a central groove 201 is provided in the sheath 2, and a fuse 1 is inserted in the center groove 201 of the sheath 2, and the two ends of the fuse 1 are led out to the protective cover. Outside the cover 2, the root 101 of the lead-out end of the fuse link 1 corresponding to the front of the sheath 2 is bent. The lead-out end of the fuse link 1 corresponding to the front of the sheath 2 is provided with a notch 102. The cross-sectional area of other positions of the piece 1, the lead-out end of the fuse piece 1 corresponding to the back of the sheath 2 is welded with a brush copper wire 3, and the fuse piece 1 is fixed in the center groove 201 of the sheath 2 through the welding spot of the brush copper wire 3 Inside.

[0012] In operation, when the current passes through the fuse 1, since the cross-sectional area of the fuse 1 corresponding to the notch 102 is the smallest, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com