A permanent magnet ball joint with built-in attitude sensor and its measuring method

A measurement method and attitude sensing technology, which is applied in the field of magnetic field sensing, can solve the problems of high precision manufacturing of spherical rolling bearings, complex structures of universal joints and Hooke hinges, and the inability to guarantee the accuracy of motion, so as to reduce vibration and Noise, good lubrication, effect of reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

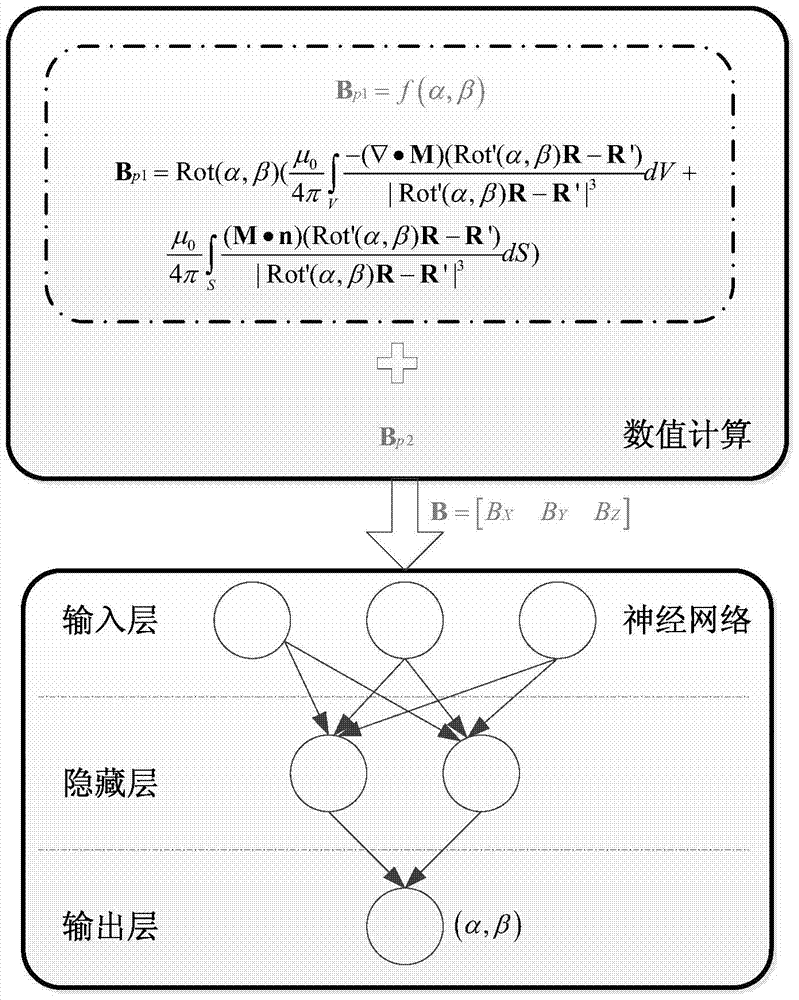

[0036] The gist of the present invention is to overcome the deficiencies of the prior art, and provide a permanent magnet ball joint with its own attitude sensor and its measurement method, which belongs to the passive magnetic bearing in the above-mentioned magnetic levitation bearing, and uses the magnetic force generated by the permanent magnet to realize the rotation of the rotor. Levitation, the Hall sensor can measure the magnetic induction intensity of the point in real time. The following will describe in detail with reference to the accompanying drawings in conjunction with the embodiments, so as to further explain the technical features and advantages of the present invention.

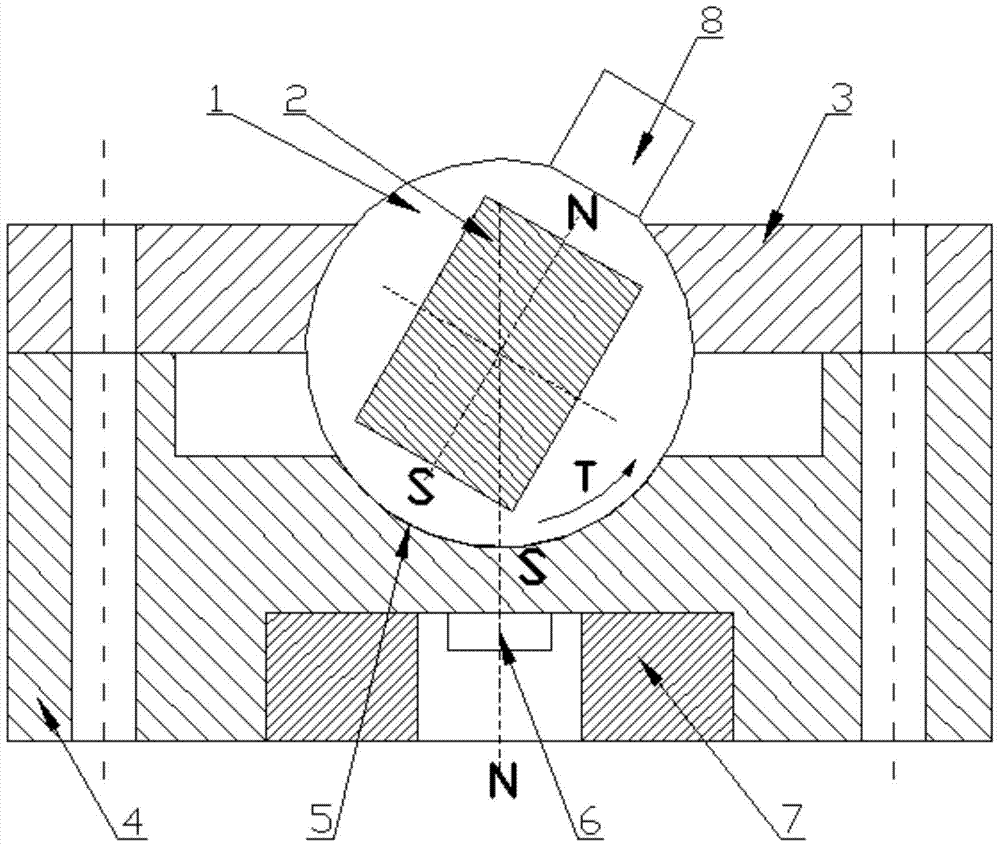

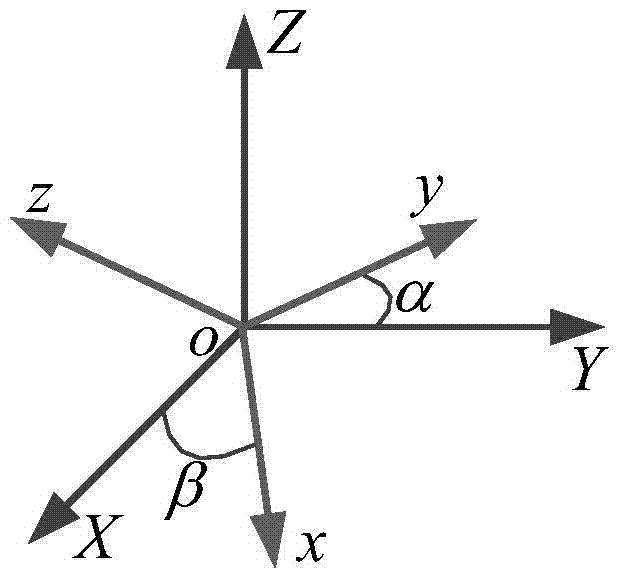

[0037] The structure diagram of the present invention is as figure 1 As shown, a permanent magnet ball joint with attitude sensing includes a permanent magnet 2, a permanent magnet 2 7, a rotating shaft 8, a spherical shell 1, an upper base 3, a lower base 4 and a Hall sensor 6; The magnet o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com