Optical fiber distributed sensing system of U-type sensing fiber deployment structure

A technology of optical fiber distribution and sensing optical fiber, which is applied in the field of optical fiber optics, information acquisition and perception, and optical engineering. It can solve the problem of the minimum integration time limiting the spatial resolution, etc., and achieve the effect of high-resolution positioning and speed measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

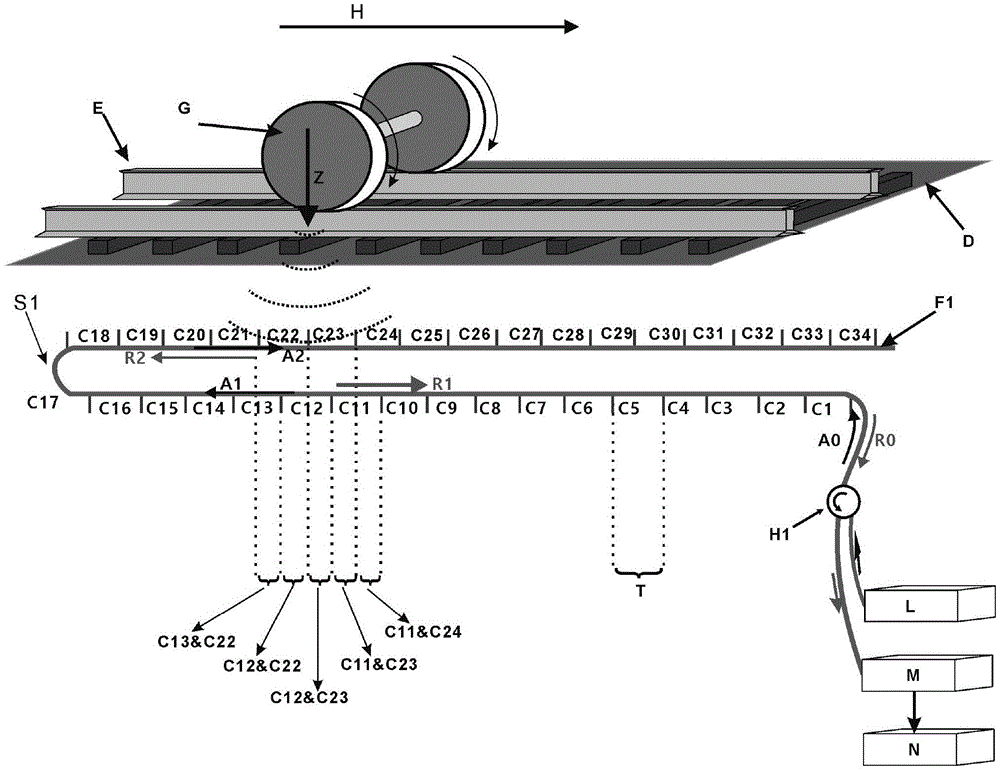

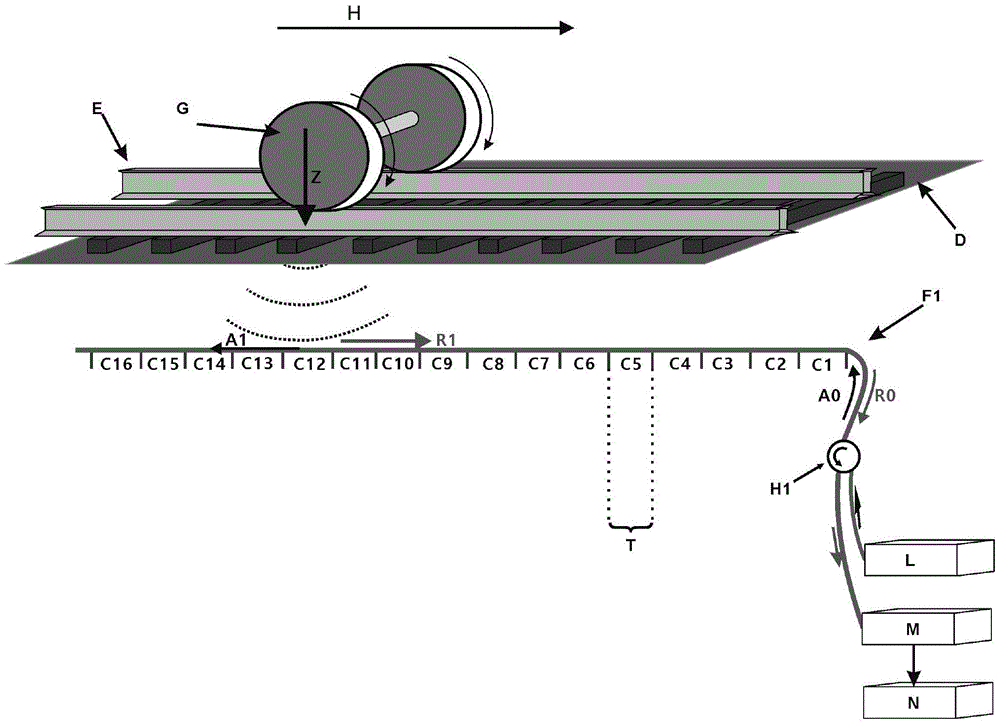

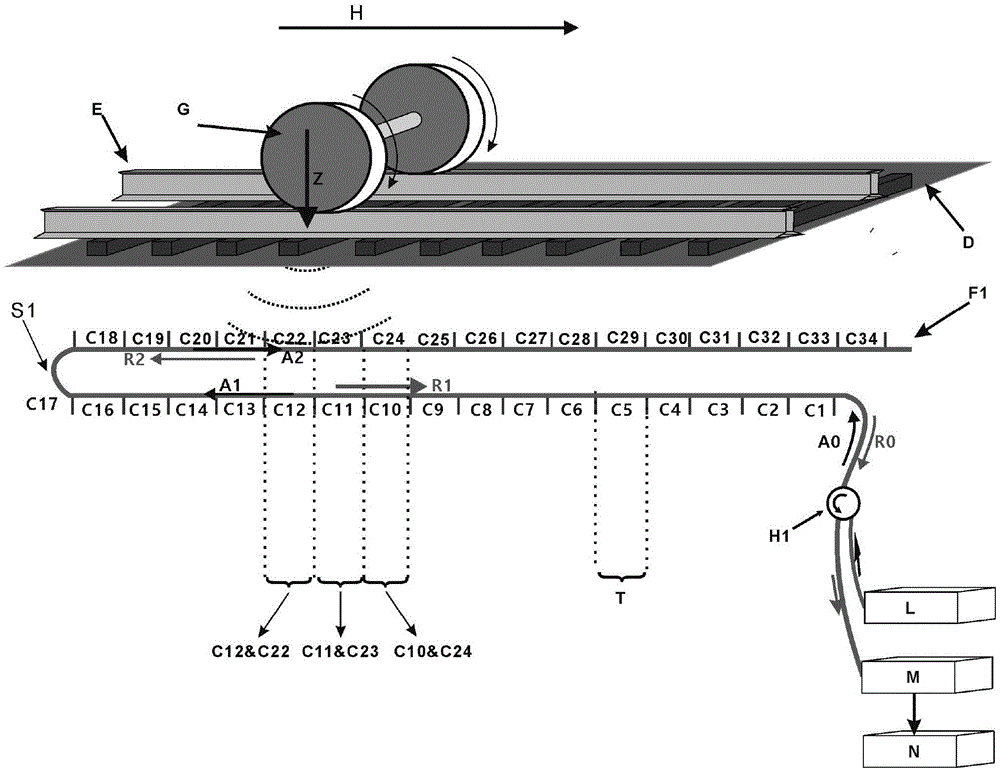

[0028] Optical fiber distributed sensing system based on single U-shaped optical fiber distribution structure

[0029] figure 1Demonstrated an optical fiber distributed sensing system based on a single U-shaped sensing optical fiber distribution structure, a single U-shaped optical fiber F1 is buried shallowly in the soil below the surface along the track, parallel to the train track and kept 20cm to the train track The linear distance of 30cm ensures that the sensing fiber maintains high sensitivity to vibration. The vibration signal (Z) generated by the movement of the locomotive on the track will act indirectly on the sensing fiber to change the transmission and scattering characteristics of the sensing fiber. According to the pulse width (T) of the pulsed laser used in the system, the sensing fiber is sequentially divided into continuous channels (C1, C2, C3...C34) with a length of (T / 2) from the laser incident end, and the incident pulsed laser A0, A1 passes through the...

Embodiment 2

[0042] Optical Fiber Distributed Sensing System Based on 3U Optical Fiber Distribution Structure

[0043] Such as Figure 5 As shown, on the basis of the above-mentioned single U interleaved distribution structure, a 3U optical fiber distribution structure can be further adopted, in which the corresponding channels have a dislocation of 1 / 4 channel length. 5-A is the vibration signal (Z) waveform generated by the wheel during motion, and 5-B is the backscattered light signal sampled by channels C55, C56, C57, C58, C59, and C60 when the light pulse is transmitted in the optical fiber Waveform, 5-C is the backscattered light signal waveform sampled by channels C49, C48, C47, C46, C45, and C44 when the optical pulse is transmitted in the optical fiber, 5-D is the channel C21 when the optical pulse is transmitted in the optical fiber , C22, C23, C24, and C25 sampled backscattered light signal waveforms, 5-E is the backscattered light signal waveform sampled by channels C13, C12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com