Counting transmission wheel train for gas meter counter

A transmission wheel train and counter technology, applied to instruments, volume metering, measuring devices, etc., can solve the problems of inflexible rotation, increase the serial movement of driven exchange gears, and reduce the adjustment efficiency, so as to improve the counting accuracy and The effect of adjusting efficiency, reducing the amount of matching deformation, and high motion precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the scope of the described embodiments.

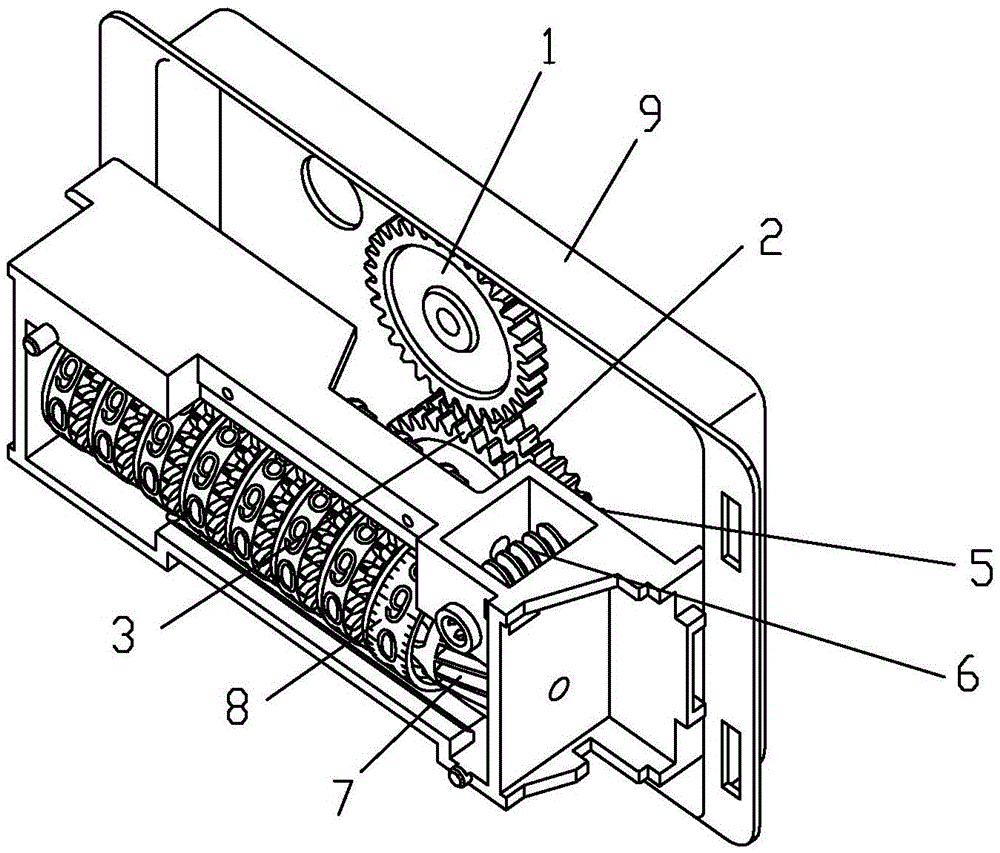

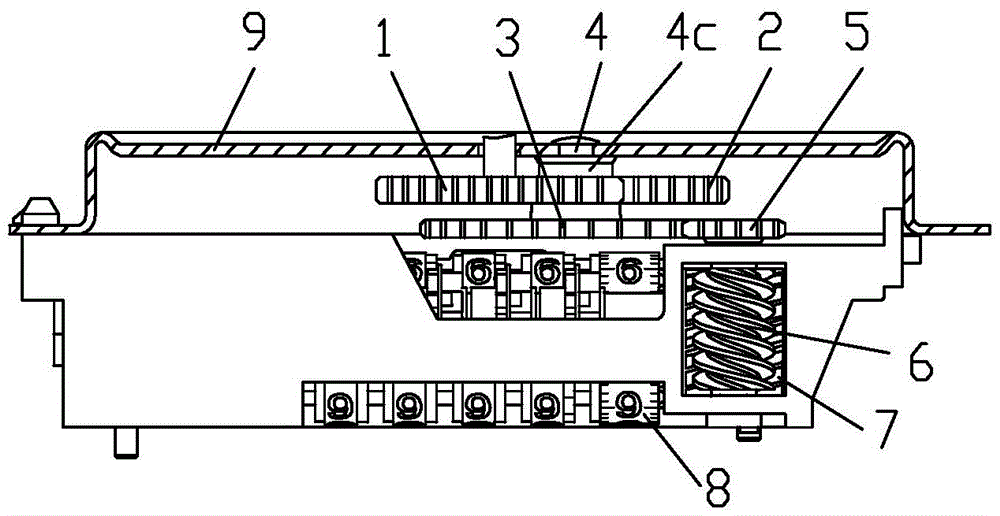

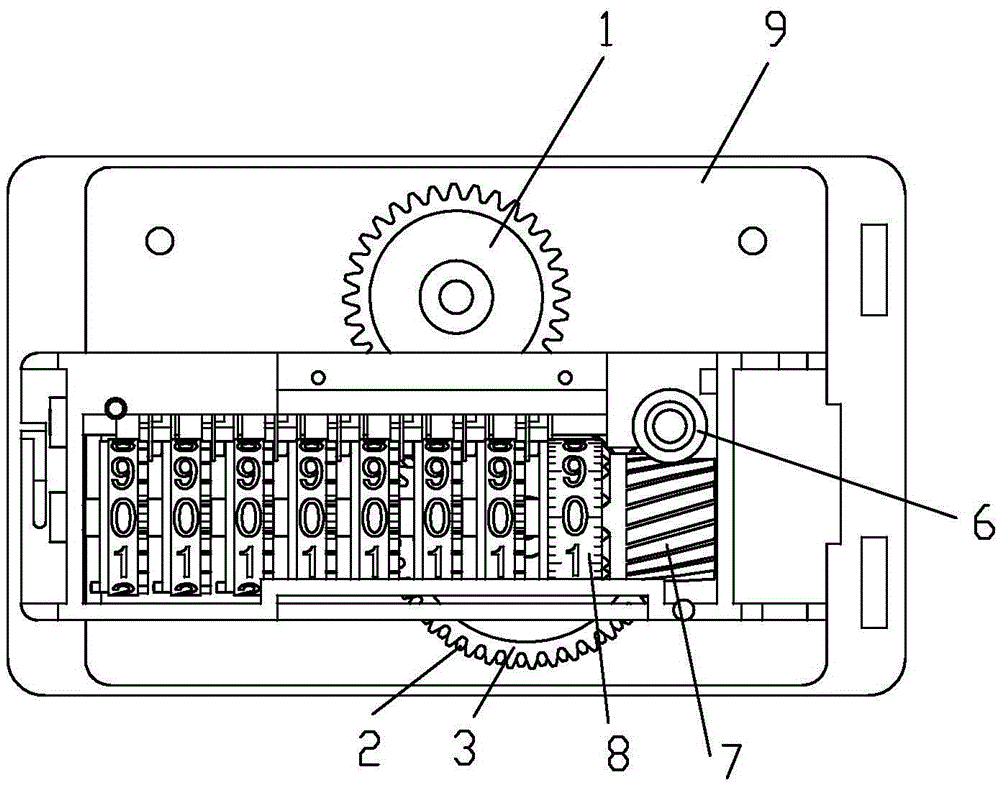

[0021] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , a counting transmission gear train for a gas meter counter, including a pair of exchange gears and a transition gear pair, the active exchange gear 1 of the exchange gear pair constitutes the input end of the gear train, and the driven exchange gear 2 of the exchange gear pair passes through the transition gear The convex ring section 3a formed in the middle of the active transition gear 3 is tightly fitted on the active transition gear 3, and the driven exchange gear 2 forms a coaxial fixed connection through the active transition gear 3, and the two are rotatable through the inner hole of the active transition gear 3 Fitted on the support shaft 4, the driven exchange gear 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com