Test piece tensile test system for optical strain field measurement under ultralow temperature environment

A tensile test and measurement system technology, applied in the direction of applying stable tension/pressure to test material strength, etc., can solve the problems of area refinement, failure to obtain mechanical performance parameters of welded joints, etc., to meet test requirements and improve welding quality , The effect of stable system operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

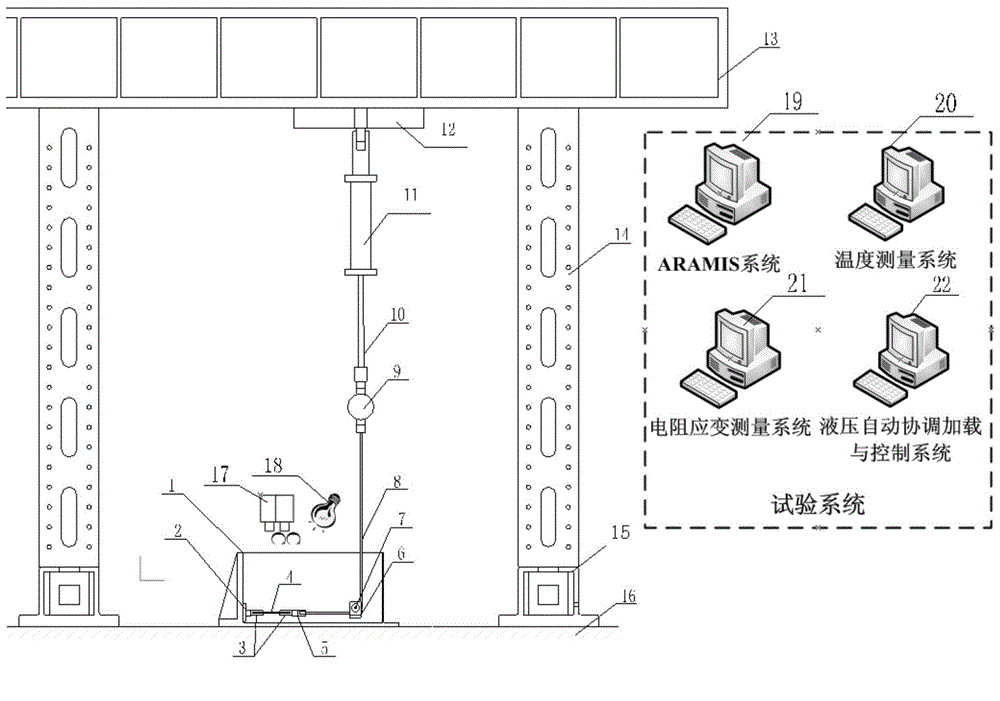

[0022] Such as figure 1 As shown, the test piece tensile test system for optical strain field measurement under the ultra-low temperature environment of the present invention includes: liquid nitrogen tank 1, fixed flange 2, test piece chuck 3, tensile test piece 4, transfer tooling 5 , pulley bracket 6, fixed pulley 7, steel wire rope 8, force sensor 9, connecting rod 10, actuator 11, adjustment plate 12, load-bearing beam 13, upright column 14, base 15, load-bearing ground rail 16, CCD camera 17 , LED light source 18, ARAMIS optical measurement system 19, temperature measurement system 20, resistance strain gauge measurement system 21, hydraulic automatic coordinated loading and control system 22;

[0023] The liquid nitrogen tank 1 is fixed on the load-bearing ground rail 16 through connecting bolts, and the fixed flange 2 is connected to the side load-bearing plate of the liquid nitrogen tank 1, and the fixed flange 2 and the first specimen chuck 3 pass through the M16 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com