Saturated humidity generator

A humidity generator and closed container technology, applied in humidity control, instruments, non-electric variable control, etc., can solve problems such as poor water vapor pressure accuracy and inability to meet demands, achieve precise control, avoid water vapor pressure fluctuations, and have a simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

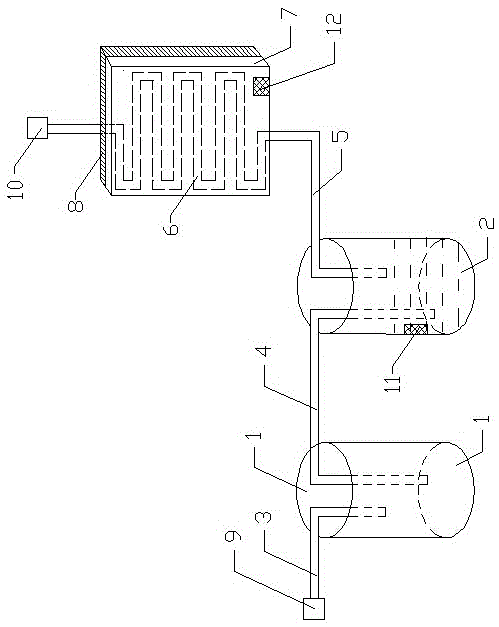

[0015] Such as figure 1 As shown, the saturated humidity generator of the present invention includes a first closed container 1, a second closed container 2 and a cooling system. The first closed container 1 and the second closed container 2 are used to fully contact the input gas with unknown water pressure with deionized water to achieve water vapor saturation; the cooling system is used to cool saturated water vapor to avoid output caused by ambient temperature fluctuations water vapor pressure fluctuations.

[0016] The air inlet end of the first gas path 3 is a gas input end, which is used to input gas with unknown water pressure. The first closed container 1 is mainly used to prevent the water liquid in the second closed container 2 from flowing back under the state of unstable pressure. The air inlet end is located at the lower part of the inner cavity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com