Data correction device, drawing device, inspection device, data correction method, drawing method, inspection method, and recording medium

A technology for data correction and design data, applied in image data processing, instruments, electrical components, etc., can solve the problem that etching correction takes a long time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

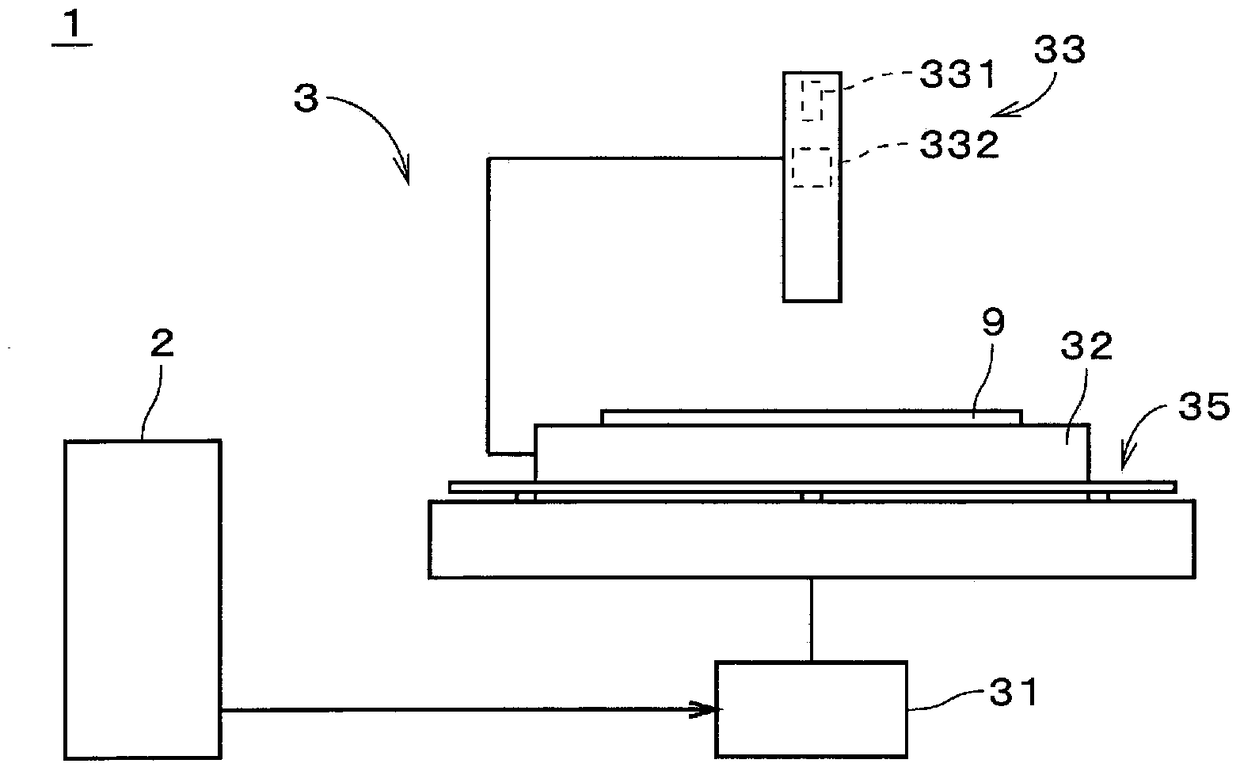

[0034] figure 1 It is a diagram showing the configuration of the drawing device 1 according to the first embodiment of the present invention. The drawing device 1 draws a circuit directly on a resist film by irradiating light to a resist film which is a photosensitive material provided on the surface of a printed board, a semiconductor substrate, a liquid crystal substrate, etc. (hereinafter simply referred to as "substrate 9"). Device for directly drawing images such as patterns. The substrate 9 on which the pattern is drawn by the drawing device 1 is developed and etched in a substrate processing device or the like (not shown). Thus, a pattern is formed on the substrate 9 . The etching of the substrate 9 is, for example, wet etching performed by applying an etchant to the substrate 9 . In addition, as the etching of the substrate 9, for example, dry etching using plasma or the like may be performed.

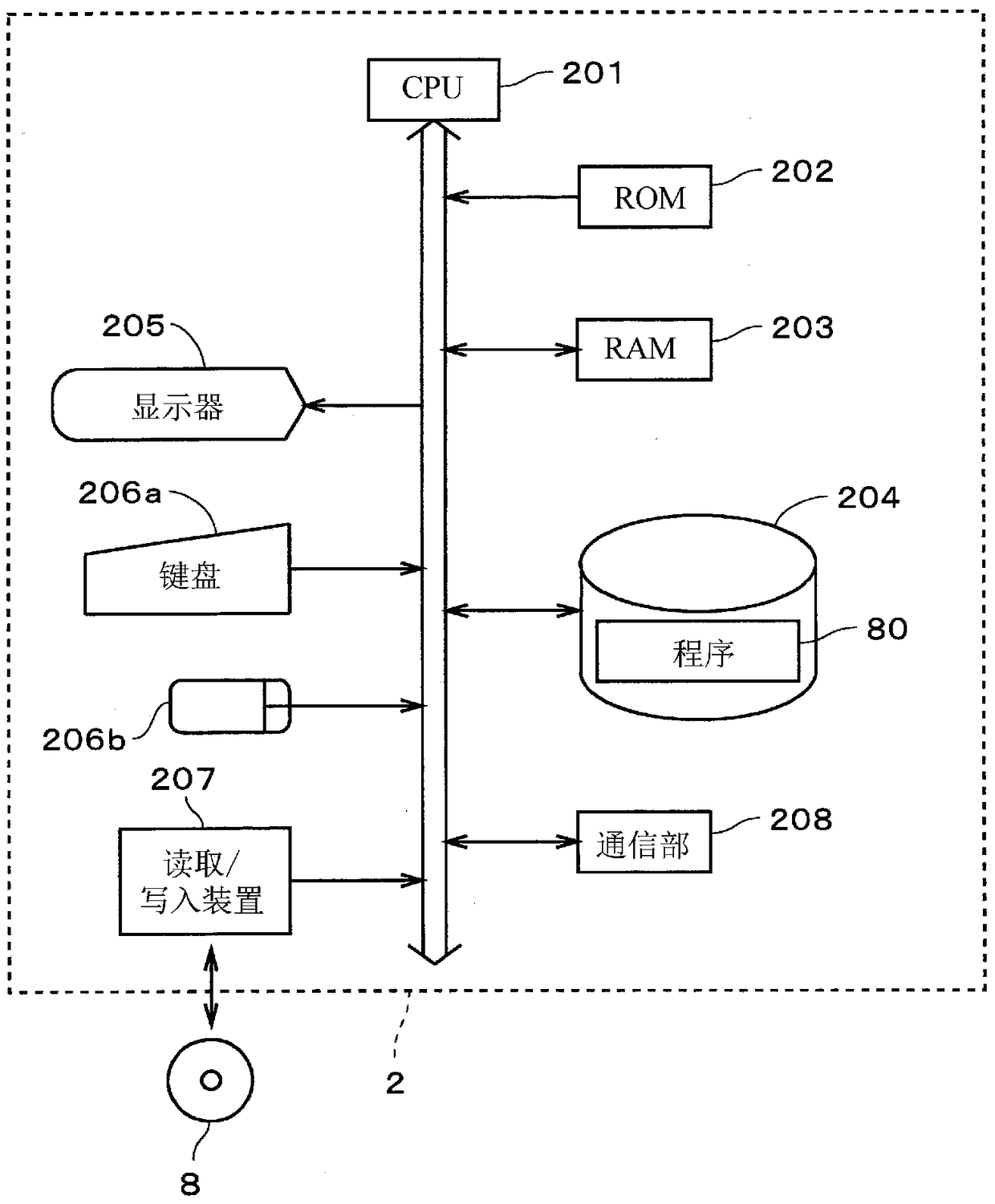

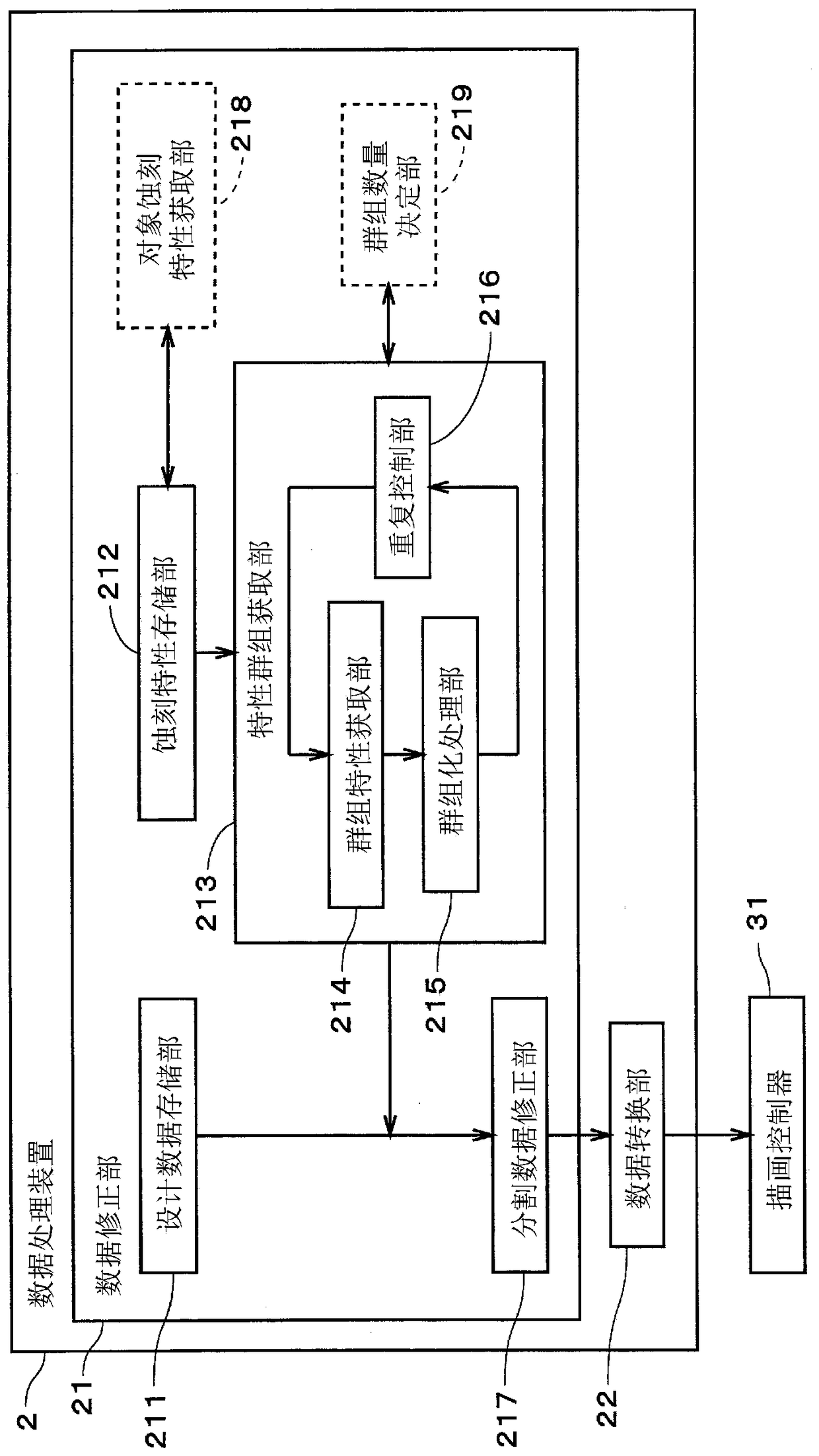

[0035] The drawing device 1 includes a data processing device 2 and an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com