Method and system for marking objects having surfaces of conductive material

A marking system and a technology for marking objects, applied in the direction of digital marking record carriers, record carriers used by machines, manufacturing tools, etc., can solve problems such as complexity and consumption, and achieve high-capacity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

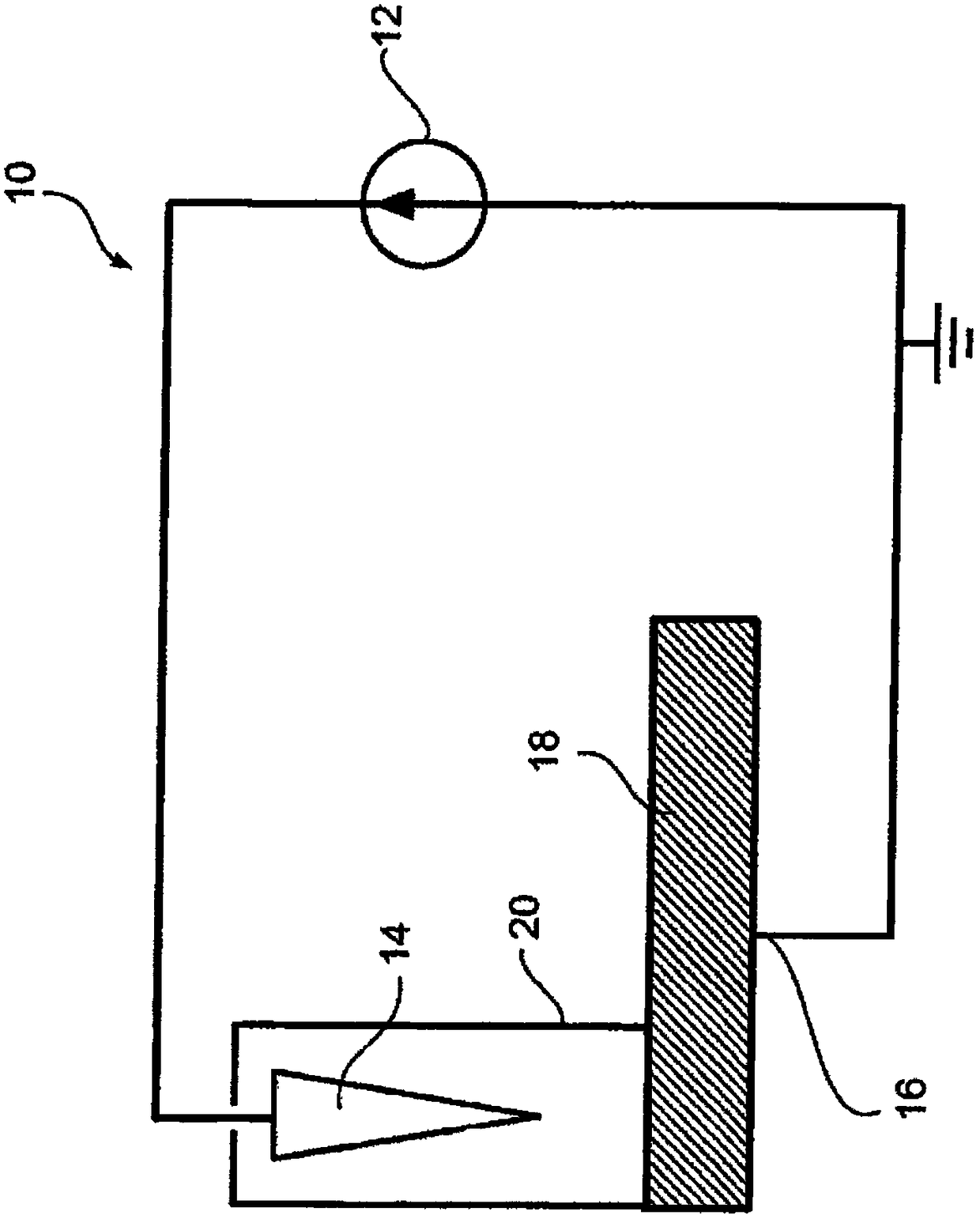

[0068] figure 1 The setup of a system 10 for marking objects 18 according to a preferred embodiment is schematically shown. A system 10 for generating sparks and thereby generating random markings as described above includes a spark generator 12, a counter electrode 14 and a connector 16 for electrically connecting the spark generator 12 to an object 18 to be marked. Optionally, the system comprises a housing 20 for controlling the protective gas environment above the object to be marked. The housing can further confine the shielding gas. Spark generator 12 is electrically connected to counter electrode 14 and object 18 .

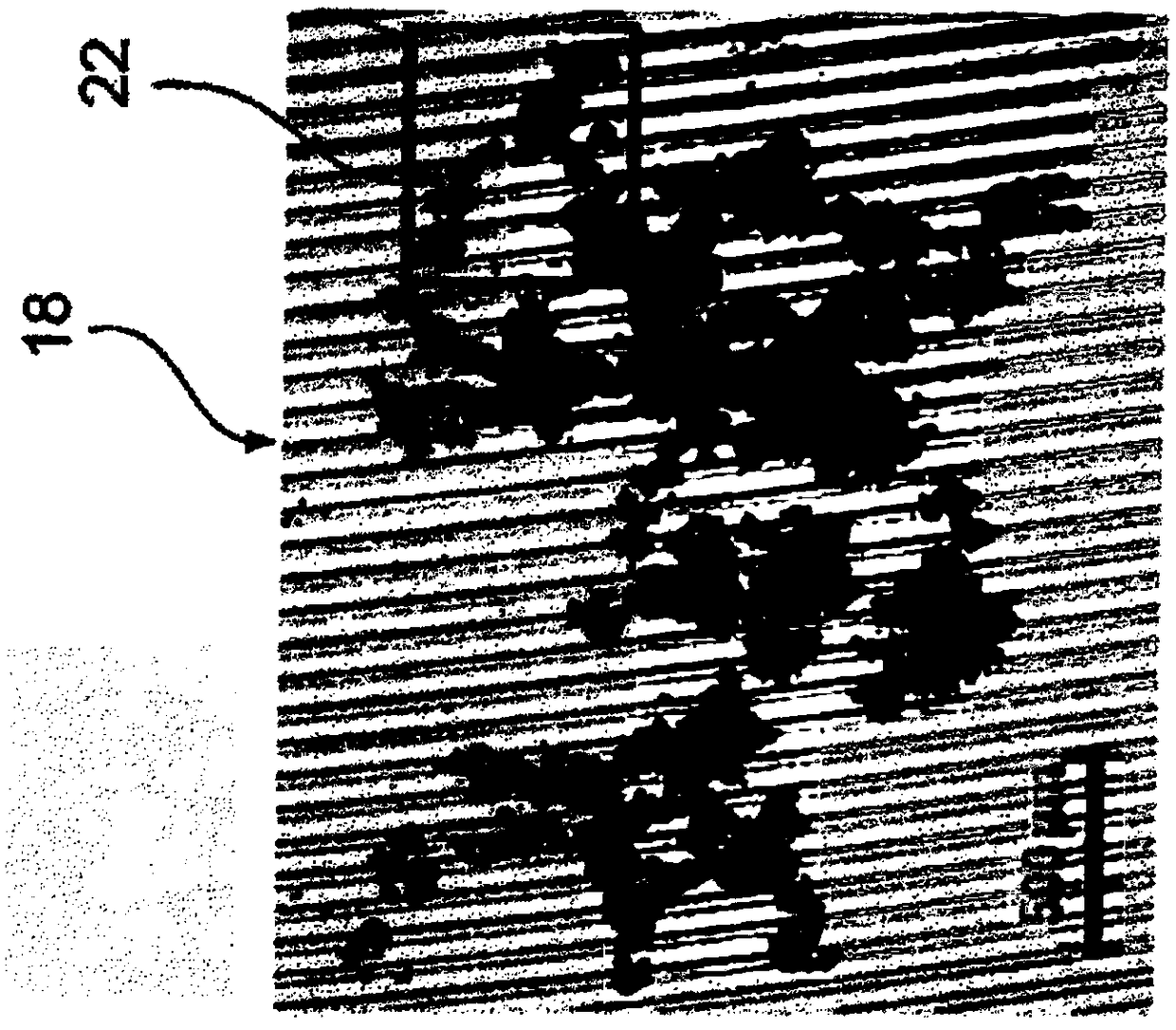

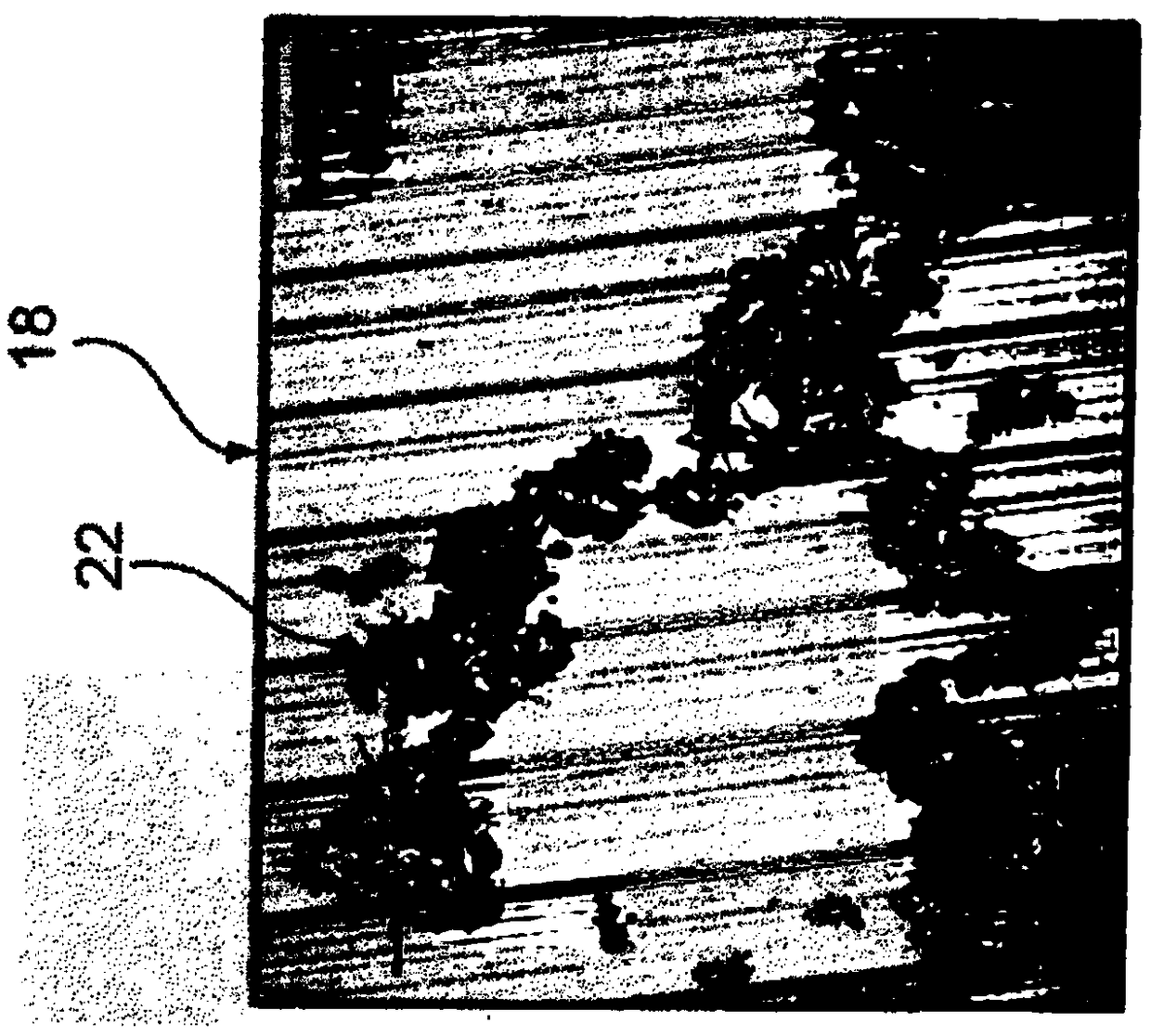

[0069] A single mark 22 obtained from a single spark generated between the counter electrode 14 and the clean and unoxidized metal surface of the object 18 may be distributed within a few square millimeters and may exhibit three-dimensional rough and fine structures. The mark may consist of hundreds of microscopic craters from which material was ablated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com