Cyanamide hydrolysis and desolventization system device

A system device, cyanamide technology, applied in the field of cyanamide hydrolysis and desolventization system device, can solve the problems of slow production efficiency, low safety factor, large space occupation, etc., achieve energy saving, increase production, and simple design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

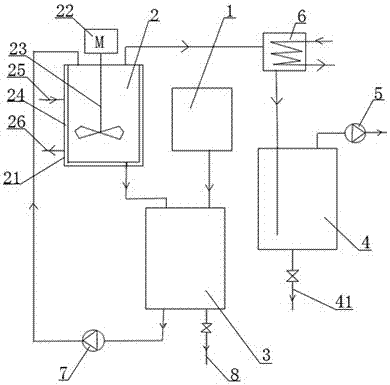

[0012] Refer to attached figure 1 , a cyanamide hydrolysis and desolventization system device, which includes a hydrolysis mechanism 1, a thin film evaporator 2, a storage tank 3, a water removal tank 4, a vacuum pump 5, and a condenser 6, and the hydrolysis mechanism 1 is connected to the upper end of the storage tank 3 through a pipeline , the outlet pipe at the lower end of the thin film evaporator 2 is connected to the upper end of the storage tank 3, the upper end of the thin film evaporator 2 is connected to the water removal tank 4 through a pipeline, the upper end of the water removal tank 4 is connected to the vacuum pump 5 through a pipeline, and the connection between the water removal tank 4 and the thin film evaporator 2 A condenser 6 is installed on the intermediate pipeline, the lower end of the storage tank 3 is connected to the upper end of the thin film evaporator 2 through a circulation pipeline, the delivery pump 7 is installed on the circulation pipeline, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com