Collection and purification system for thermal processing and oil fume processing

A technology of oil fume purification and purification system, which is applied in the direction of smoke removal, chemical instruments and methods, cleaning methods and utensils, etc., which can solve the problems of easy inhalation of flames, large air volume, wind speed and negative pressure, oil fume overflow, etc., to ensure oil fume Collection effect, effect of securing the ventilation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

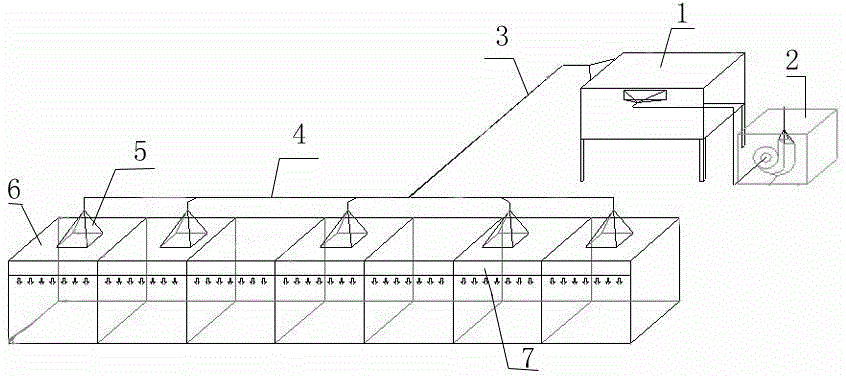

[0018] The present invention as figure 1 As shown, the oil fume collection and purification system of the heat treatment quenching line is taken as an example.

[0019] Heat treatment oil fume treatment and collection evolution system, including oil fume purification device 1, oil fume purification device 1 with suction fan 2, oil fume purification device 1 connected with main air duct 3, main air duct 3 is connected with sub-air duct 4, sub-air duct 4 A plurality of exhaust top covers 5 are connected with an integral wind cover 6, the two ends of the integral wind cover 6 are closed, and the front and rear sides are provided with air curtains 7 to lock the wind vertically.

[0020] A plurality of exhaust top covers 5 are cone-shaped, and the negative pressure zone of the air suction port of the exhaust top covers 5 is 2-2.5 meters away from the liquid surface of the oil tank.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com