A method for controlling residual stress and machining deformation of precision structural parts

A precision structural parts, processing deformation technology, applied in the field of residual stress and processing deformation control of precision structural parts, can solve the problems of large processing deformation of precision structural parts, long production cycle, unstable process, etc., to shorten the production cycle and reduce labor Intensity, inhibition of gradual cumulative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below with reference to specific embodiments. The exemplary embodiments and descriptions of the present invention are used to explain the present invention, but are not intended to limit the present invention.

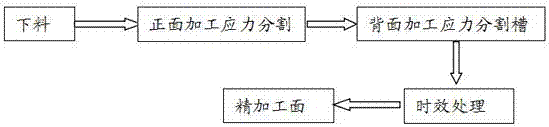

[0026] like figure 1 A method for controlling residual stress and machining deformation of precision structural parts is shown, including the following steps:

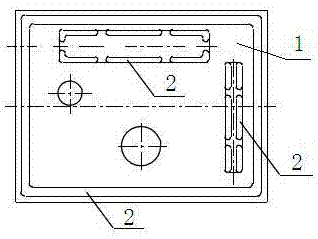

[0027] 1) A stress separation groove is machined on the front of the precision structural part at a distance of 8-10mm from the periphery. The groove width is 10-16mm, and the groove depth is 0.5mm allowance to the finished product size. Cutting parameters:

[0028] Speed: 6000~8000 r / min,

[0029] Feed rate: 400~600 mm / min,

[0030] Cutting depth: 1~1.5 mm,

[0031] Tool: carbide tool;

[0032] 2) Repeat step 1) to machine the stress dividing groove on the back of the precision structural part;

[0033] 3) The above-mentioned precision structural part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com