Shaft part polishing mechanism with high flexibility and use method thereof

A shaft part and polishing mechanism technology, applied in the polishing field, can solve the problems of complex workstation transfer steps, complex control procedures, etc., and achieve the effects of convenient use, simple device structure and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

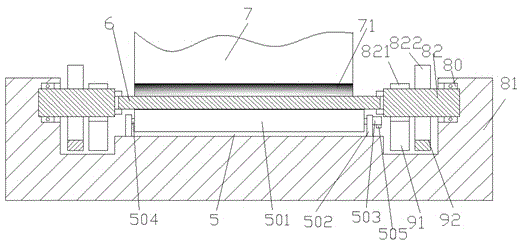

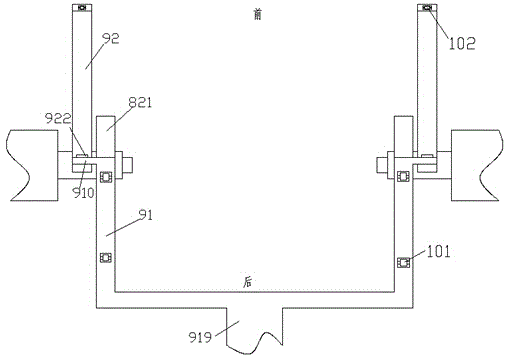

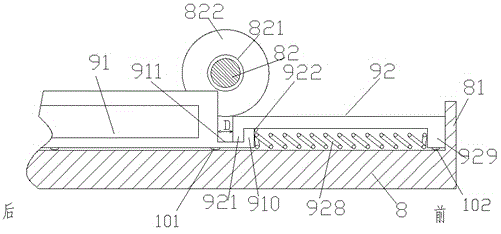

[0010] Combine below Figure 1-3 The present invention will be described in detail.

[0011] A highly flexible polishing mechanism for shaft parts 6 according to an embodiment includes a polishing component 7 with a polishing strip 71 and a support base 8, and the two ends of the support base 8 are rotatably supported by bearings 80 respectively. There are clamping drive parts 82 symmetrically arranged on the left and right, and the two clamping drive parts 82 are arranged opposite to each other so as to clamp the two ends of the shaft part 6 in place. The circumferential surface of each clamping drive part 82 The large gear 822 on the outer side and the pinion gear 821 on the inner side are fixedly installed on it, and are used to respectively mesh with the outer rack 92 and the inner rack 91 arranged symmetrically so as to drive the shaft part 6 against the polishing pad. The bar 71 is relatively rotated with respect to the polishing bar 71 so as to carry out the polishing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com