A robot elastic joint with adjustable stiffness

A technology of elastic joints and robots, applied in the directions of manipulators, manufacturing tools, joints, etc., can solve the problems of poor versatility, non-linear adjustment of stiffness, loose flexible joint structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The purpose of the present invention will be further described in detail through specific examples below, and the examples cannot be repeated here one by one, but the implementation of the present invention is not therefore limited to the following examples.

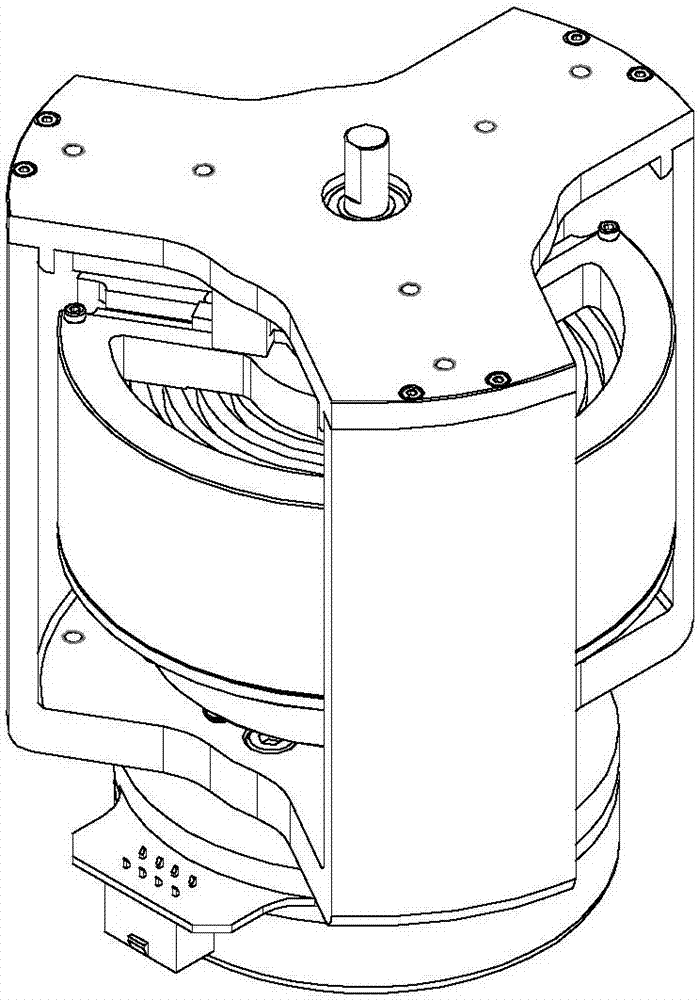

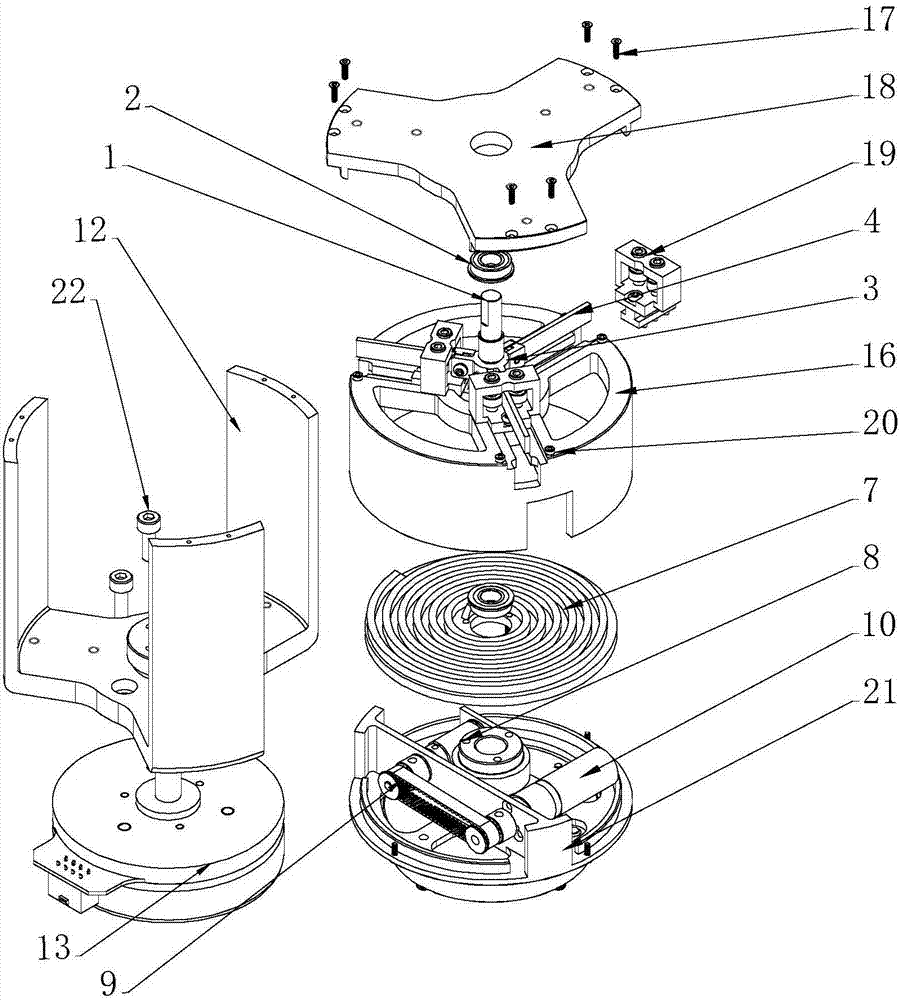

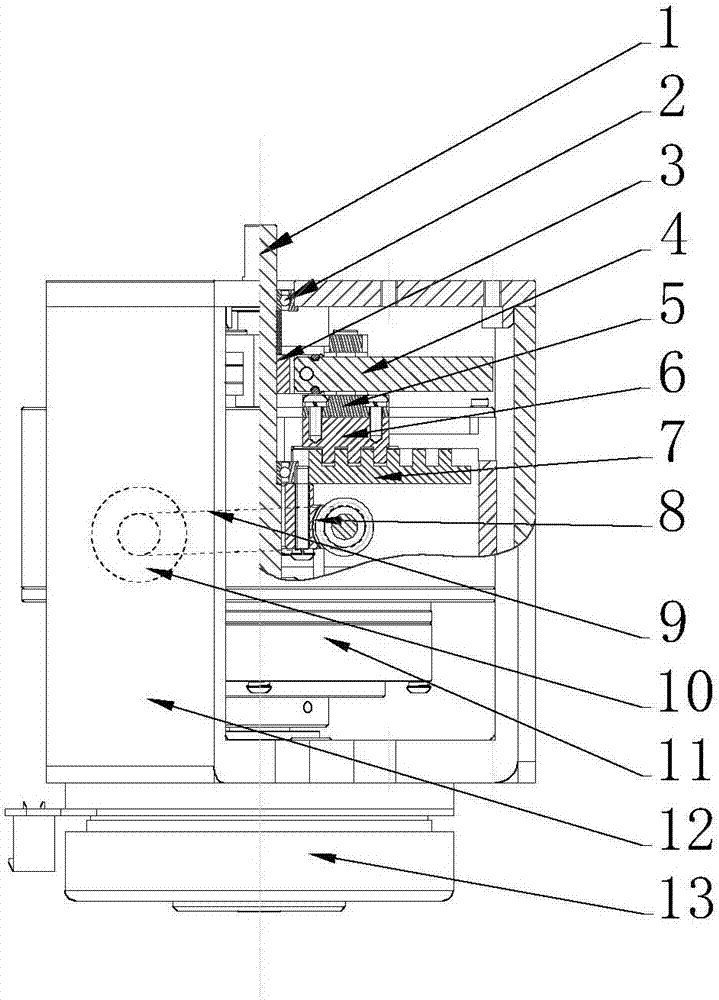

[0026] like Figure 1 to Figure 4 As shown, a robot elastic joint with adjustable stiffness includes a joint skeleton, a driving end and an output shaft 1 respectively arranged at both ends of the joint skeleton, and also includes a 1, the stiffness adjusting device includes a rotating body connected to the driving end, an elastic force transmission member connected between the rotating body and the output shaft 1 and rotating around the axis of the output shaft 1 under the push of the rotating body, When the output shaft 1 is impacted by different loads, it is an adjustment mechanism for adjusting the length of the force arm when the rotating body drives the elastic force transmission component to rotate.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com