Special pad for self-stabilizing prefabricated pipeline cross reinforcement

A criss-crossing and self-stabilizing technology, applied in the field of block fixation and cross-bar protective layer control, can solve problems such as difficulty in fixing, tying of cushion blocks, and no protective layer for pipeline steel bars, so as to improve the connection firmness and ensure Connection angle, easy to carry by hand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is mainly suitable for fixing steel bars with a diameter of 6mm-20mm. This embodiment takes the situation of fixing a steel bar with a diameter of 8mm as an example to describe the dimensions of each structure of the self-stabilizing prefabricated pipeline crossing steel bar special spacers. The structural dimensions can be based on Adjust accordingly for different diameters of steel bars.

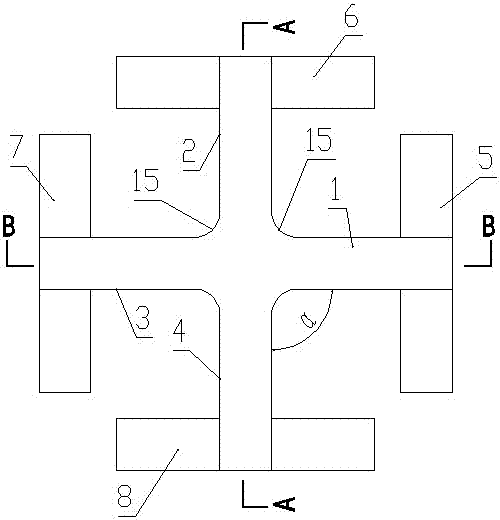

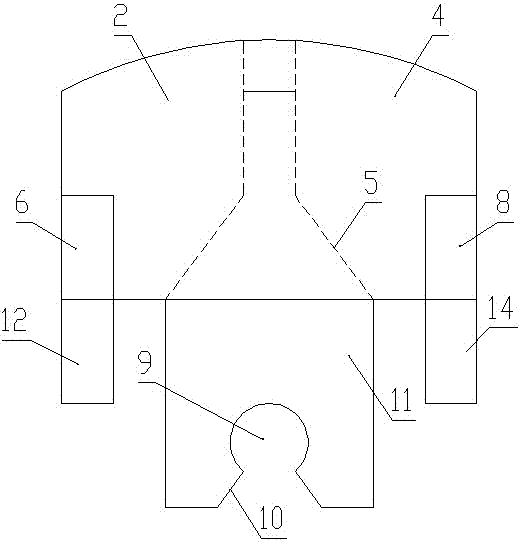

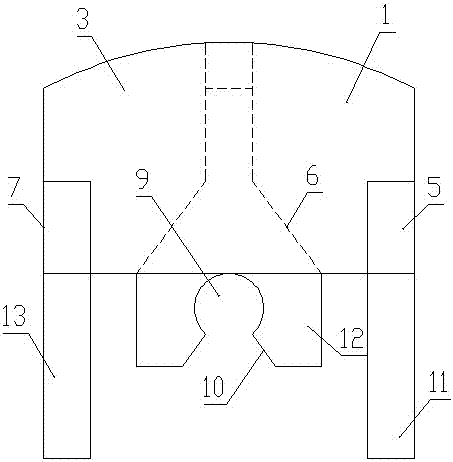

[0020] Such as figure 1 , figure 2 and image 3 As shown, the self-stabilizing prefabricated pipeline cross reinforcement special pad of the present invention includes a cross plate, and the cross plate is bounded by its intersection to form four plate surfaces, which are the first plate surface 1 and the second plate surface 2 in turn. , the third deck 3 and the fourth deck 4, the angle α between two adjacent decks is 90 degrees; the outer ends of the first to fourth decks 1, 2, 3, 4 are all downward An isosceles triangle connecting plate with a narrow top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com