Method for compensating failed printing nozzles in inkjet printing system

A technology of inkjet printers and nozzles, applied in printing, printing devices, etc., can solve problems such as hardware redundancy and low efficiency, and achieve the effects of avoiding overcompensation, improving image quality, and eliminating redundant structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

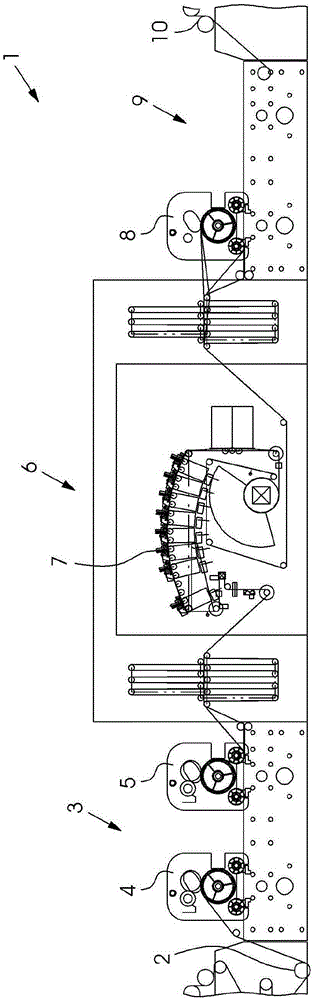

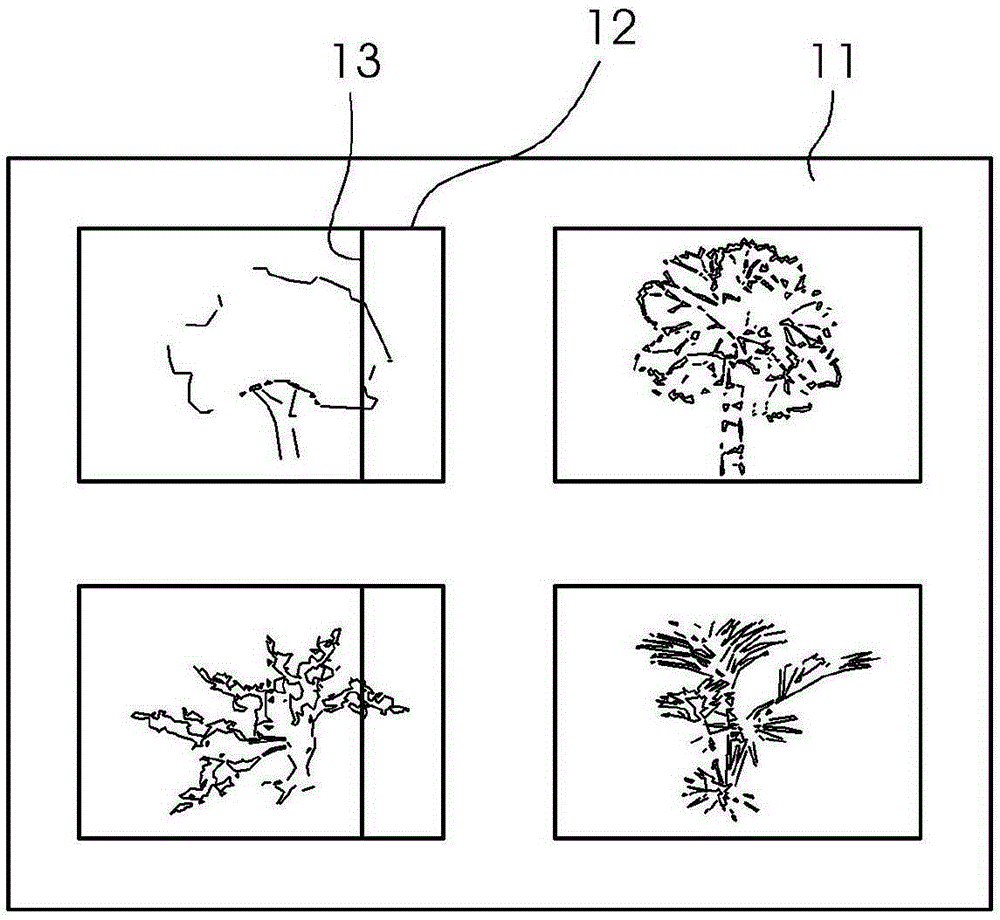

[0047] In a preferred embodiment variant, this field of application is the inkjet printing machine 1 . exist figure 1 An example of a structure for such a machine 1 is shown in . During operation of the printing press 1 , as already explained at the outset, individual printing nozzles in the printing head 7 in the printing unit 6 can become deactivated. The result is then a white line 13, or, in the case of multicolor printing, distorted color values. An example of such a white line 13 is in figure 2 shown in .

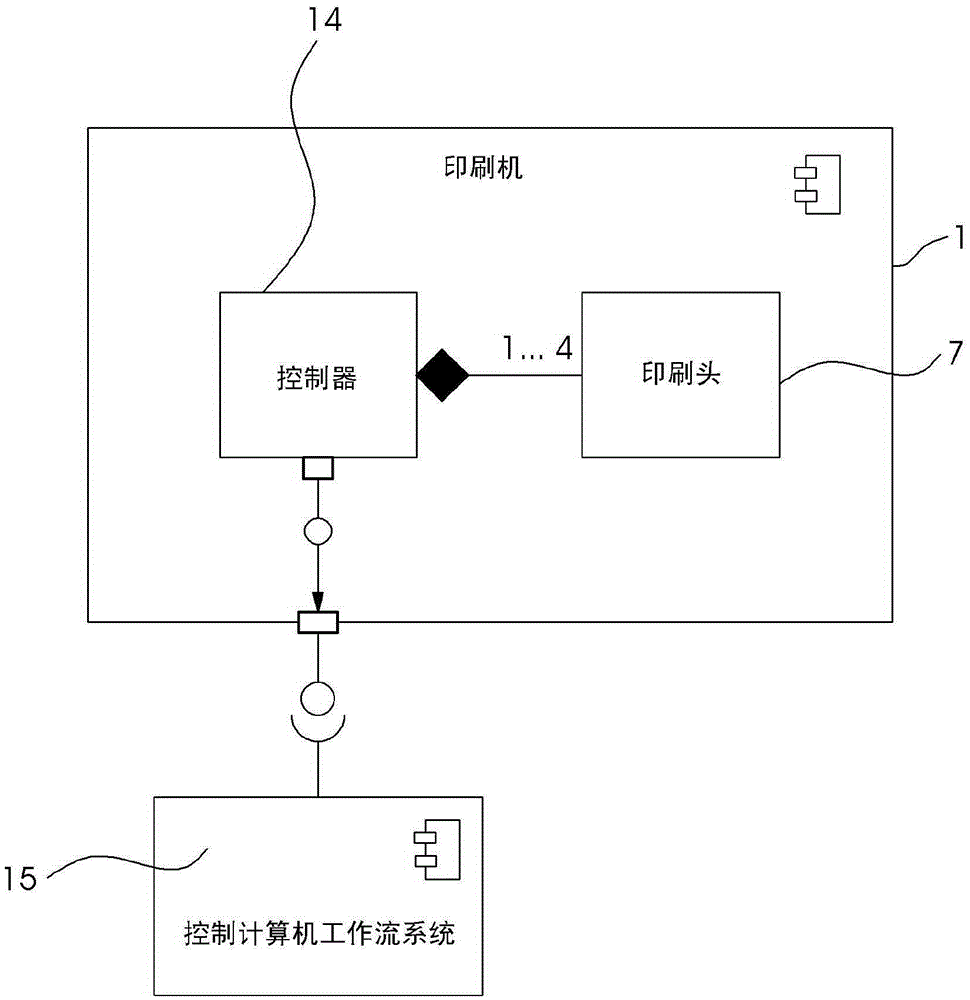

[0048] Since the described method is inefficient to be carried out manually by a user, this execution is carried out automatically by the control computer 14 of the inkjet printer 1 . image 3 An exemplary structure of such a system is shown. This automated method is integrated into the workflow of the printing press 1 here. The configuration of the control computer 15 with respect to the individual method steps can be corrected manually by the user if necessar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com