Vehicular hydraulic braking supercharger and braking pressure distributing system

A hydraulic brake and supercharger technology, which is applied in the direction of brakes, brake transmissions, vehicle components, etc., can solve problems such as hidden dangers of unloading spring failure, eliminate hidden dangers of booster function disappearance, and improve safety and reliability The effect of low resistance and processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

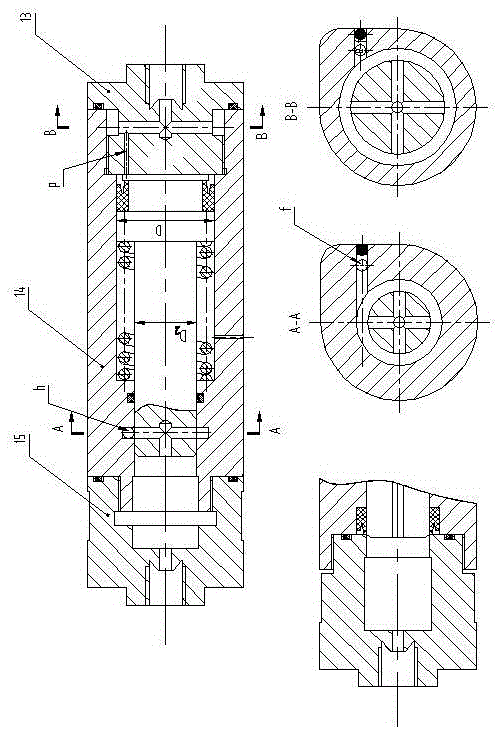

[0017] control figure 1 The first embodiment of the hydraulic brake booster of the present invention will be described in detail.

[0018] The hydraulic brake booster includes a housing 1, a booster piston rod 2, a return spring 3 and a sealing ring 4 for the hole. The booster piston rod 2 is provided with a large end and a small end, and the diameter of the small end is D 2 , the big end diameter is D 1 and D 1 >D 2 ; The housing 1 is composed of a high-pressure chamber housing 11 and a low-pressure chamber housing 12, which are connected by threads. The high-pressure brake fluid output port O is set on the high-pressure chamber housing 11 1 and the high-pressure chamber K, and the brake fluid input port O is set on the low-pressure chamber housing 12 2 and low-pressure chamber G, after housing 1 is assembled, the brake fluid input port O 2 , low-pressure chamber G, high-pressure chamber K, high-pressure brake fluid output port O 1 The low-pressure chamber G and the hi...

Embodiment 2

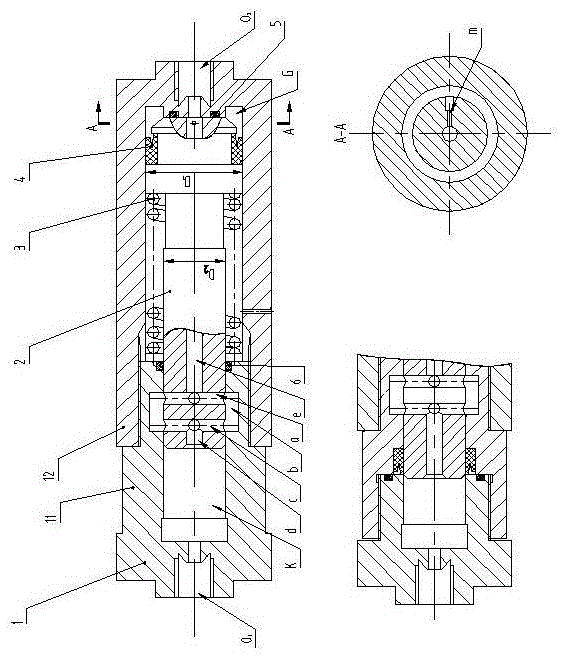

[0029] figure 2 It is another embodiment of the hydraulic brake booster of the present invention.

[0030] The forms of the first through hole and the first lead-out hole in this embodiment are the same as those in the previous two embodiments. The form of the second lead-out hole is an annular groove b corresponding to the first lead-out hole, and the second through hole consists of a hole f drilled in the axial direction of the housing 1 and a radially drilled hole corresponding to the position of the ring groove b h, brake fluid input port O 2 It communicates with hole h.

[0031] figure 2 Among them, the housing 1 includes an end cover 13, and the end cover 13 is provided with a low-pressure brake fluid input hole O 2 , the input hole O 2 Communicate with the second through hole.

[0032] The throttle hole is in the form of a hole p processed axially along the end cover 13, and the hole p is connected with the low-pressure brake fluid input hole O 2 connected. In...

Embodiment 3

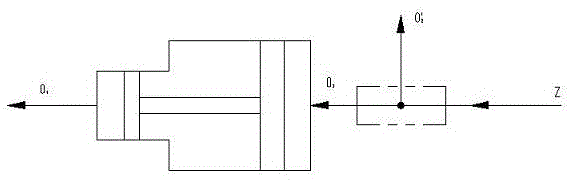

[0037] image 3 It is a working principle diagram when the vehicle brake control system is constructed by adopting the above embodiments.

[0038] booster and tee fittings ( image 3 The part surrounded by double dotted lines) constitutes the brake pressure distribution system. The low-pressure brake fluid is input from the Z port, divided into two routes through the three-way pipe joint, and one route is O’ 2 The port outputs low-pressure brake fluid to the low-pressure wheel brake cylinder, and the other path passes through the supercharger from O 1 Output high-pressure brake fluid to the high-pressure brake wheel cylinder.

[0039] The braking method shown in this embodiment is also a general implementation mode when the existing hydraulic brake booster needs to distribute high and low pressure brake fluid, and its characteristic is that a three-way pipe joint or similar parts must be used to realize pressure division.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com