Tipping mechanism

A tipping bucket and body technology, applied in the field of automatic management machines, can solve the problems of belt lengthening, fatigue damage, high manufacturing cost, etc., and achieve the effects of low manufacturing cost, long service life and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

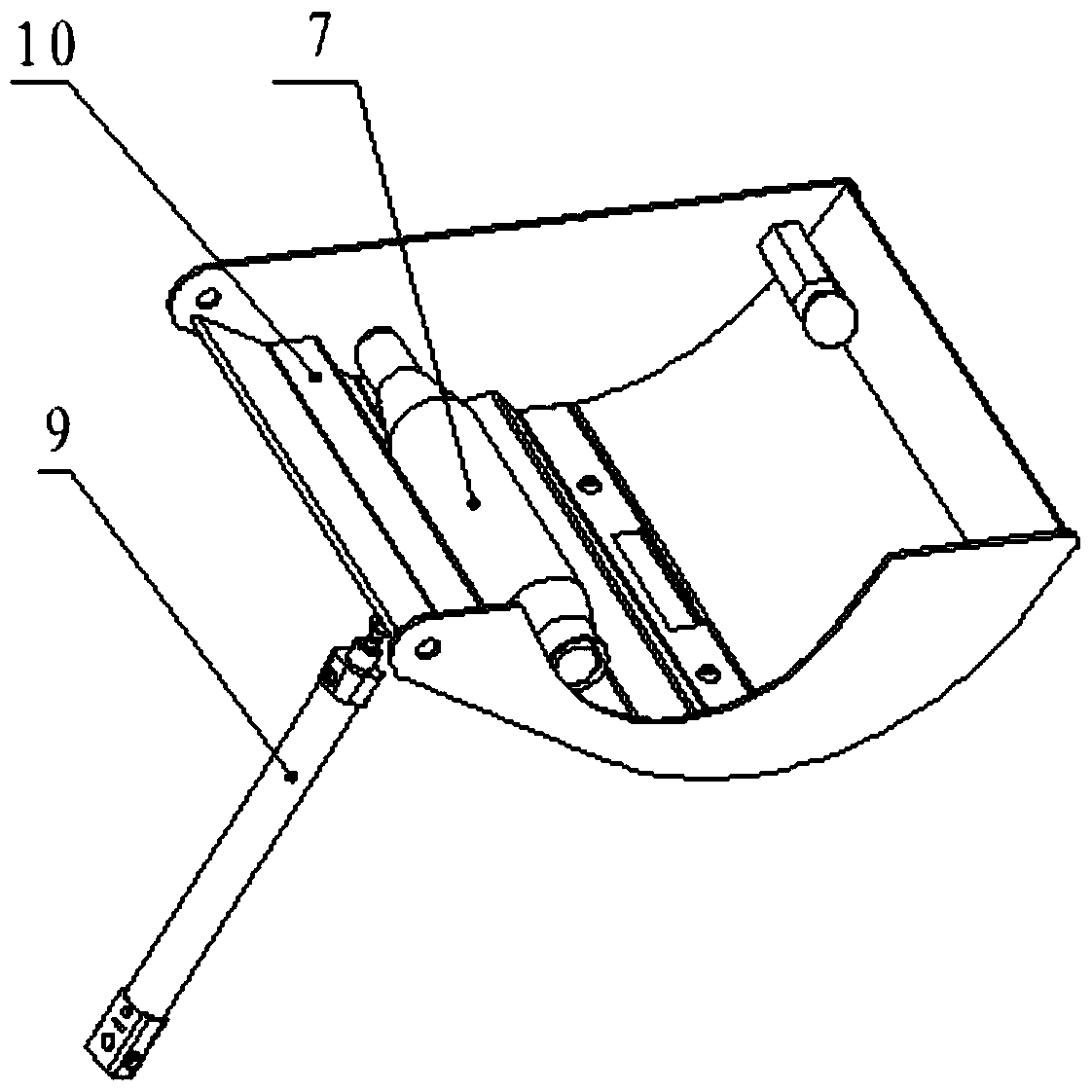

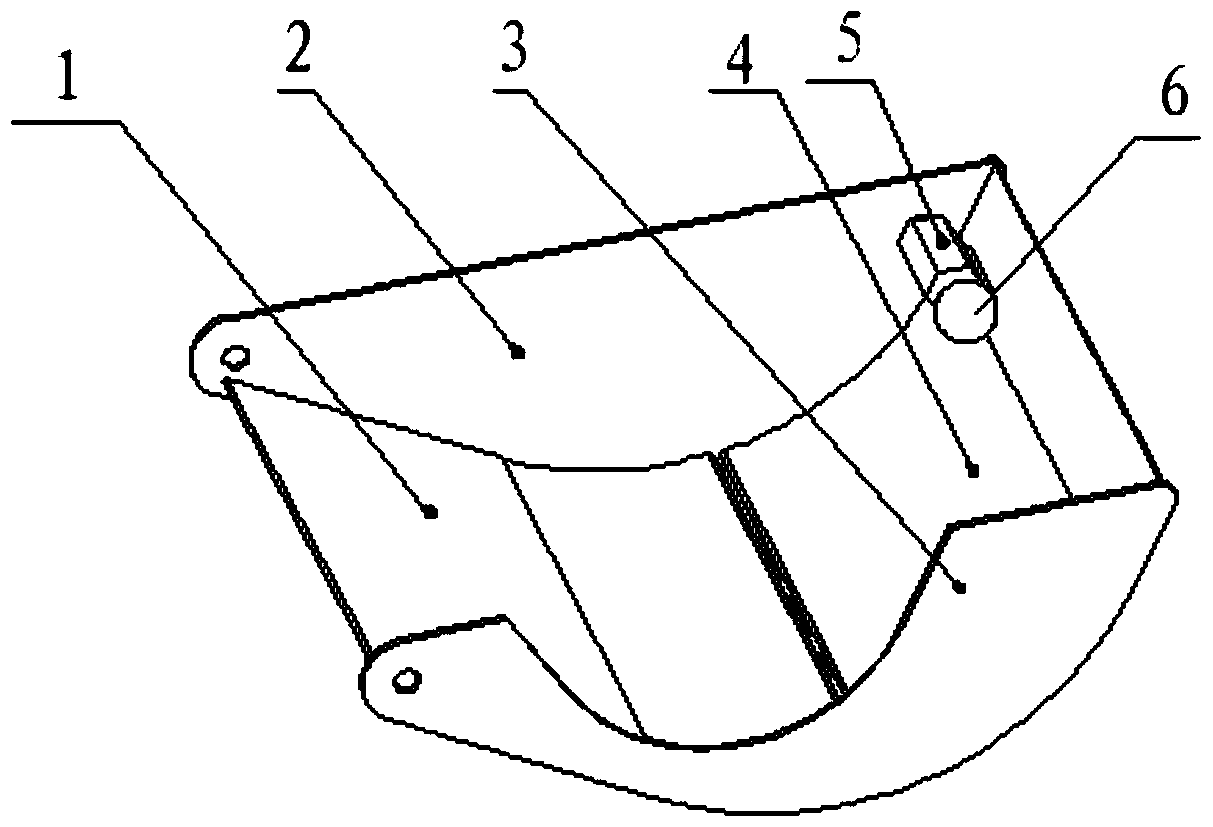

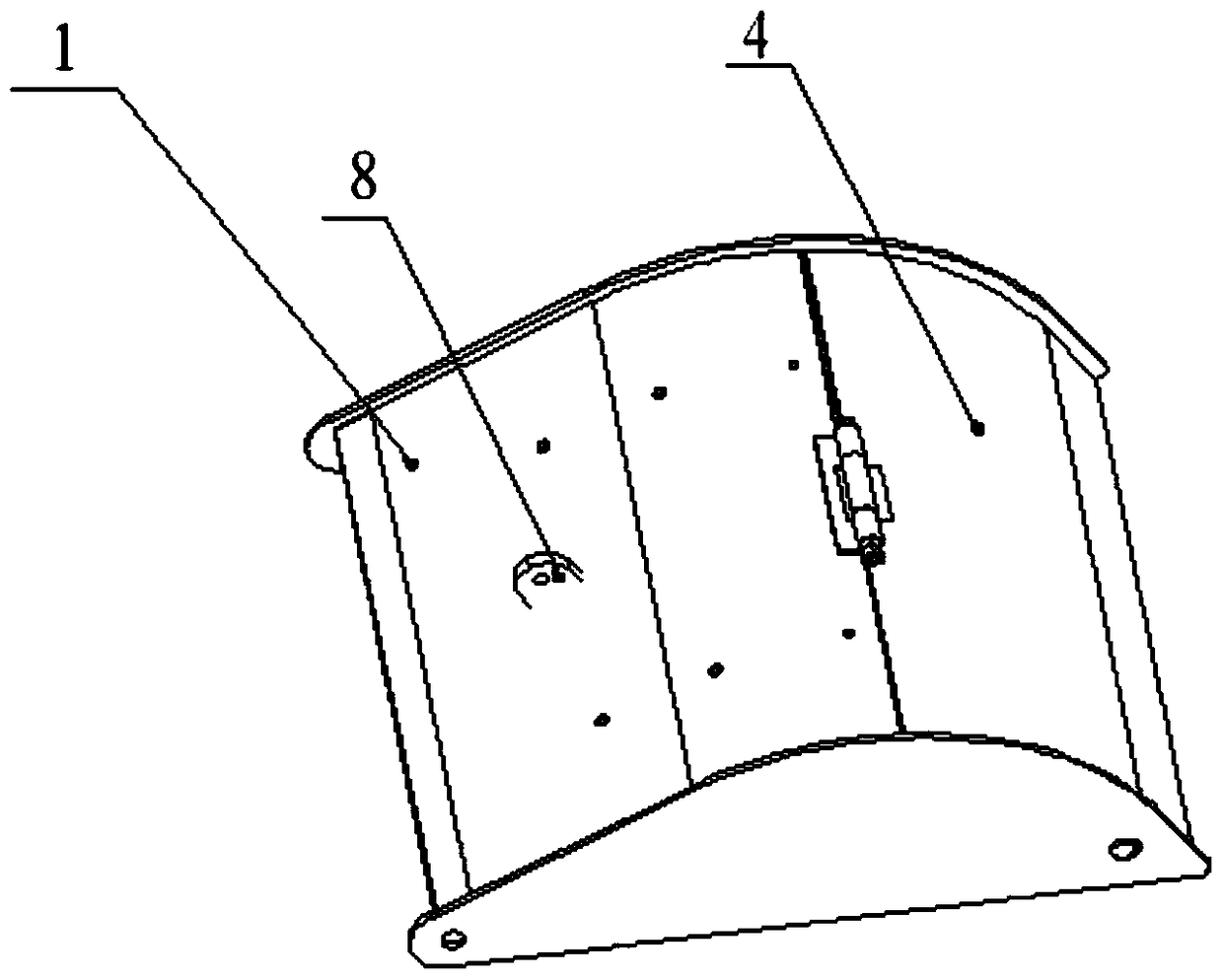

[0020] Embodiment: a dumping mechanism, including a dumping bucket body and a driving device. The bottom surface of the dumping bucket body is in a scoop-shaped arc structure. The dumping bucket body can swing back and forth along the arc curve of its bottom surface on the management machine. The discharge end is formed on one side of the extension direction of the arc-shaped curve of the bottom surface, and an opening is formed on the side wall of the side wall of the tipping bucket body perpendicular to the extension direction of the bottom surface curve. Drive the dump body to swing on the management machine.

[0021] When working, the driving device pushes the body of the tipping bucket to swing within 0°~60°, and the spun bobbin 7 rolls down to the next process in an orderly manner along the inner arc surface of the tipping bucket body to complete the action of taking over and delivering tubes.

[0022] The dump body includes a fixed bottom plate 1, a movable bottom plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com