Ammonia-nitrogen wastewater resourceful treatment system and treatment method of ammonia-nitrogen wastewater resourceful treatment system

A treatment system, ammonia nitrogen wastewater technology, applied in multi-stage water treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problem of high consumption of iron carbon and hydrogen peroxide, decreased total nitrogen content of ammonium salts, and secondary pollution of the surrounding environment and other problems, to achieve the effect of small solid waste output, small floor space and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

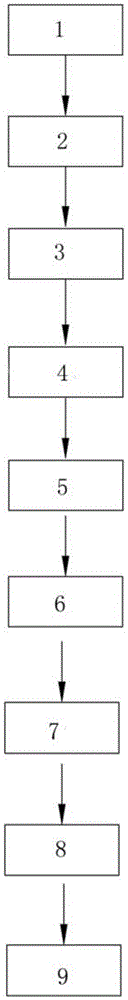

[0041] A resource-based treatment system for ammonia-nitrogen wastewater according to the present invention, the system includes a water collection tank 1, a buffer tank 2, a regulating tank 3, a first buffer tank 4, an MVR evaporation system 5, a regulating tank 6, and an adsorption system 7. The second buffer tank 8, ammonia nitrogen removal system 9; the sump 1, the buffer tank 2, the regulating tank 3, the first buffer tank 4, the MVR evaporation system 5, the regulating tank 6, the adsorption system 7, the second buffer tank 8. The ammonia nitrogen removal system 9 is equipped with an inlet and an outlet;

[0042] The outlet of the sump 1 is connected with the inlet of the buffer tank 2, the outlet of the buffer tank 2 is connected with the inlet of the regulating tank 3, and the outlet of the regulating tank 3 is connected with the inlet of the first buffer tank 4, The outlet of the first buffer tank 4 is connected to the inlet of the MVR evaporation system 5, the outlet...

Embodiment 2

[0070] The difference between embodiment 2 and embodiment 1 is that: the front portion of the sump 1 is provided with a grid device; For large suspended solids, the outlet of the coarse grid is connected to the inlet of the fine grid through pipes, the gap of the fine grid is 8mm, and the outlet of the fine grid is connected to the pipeline sump 1;

[0071] The adjusting kettle 3 adjusts the pH value of the wastewater to 6 during the stirring process; the residence time of the wastewater in the adjusting kettle 3 is 80min, and thiourea dioxide is first added in the kettle, and the added quality of the thiourea dioxide is 0.3% of the wastewater quality, and then the adsorption Powdered activated carbon, the mass of activated carbon added is 0.8% of the waste water quality, the anti-coking agent inhibits the oxidation and polymerization of aromatic organic matter in waste water to produce tar-like substances under high temperature conditions, activated carbon absorbs and removes ...

Embodiment 3

[0094] The difference between embodiment 3 and embodiment 1 is that: the front portion of the sump 1 is provided with a grid device; For large suspended solids, the outlet of the coarse grid is connected to the inlet of the fine grid through pipes, the gap of the fine grid is 10mm, and the outlet of the fine grid is connected to the pipe sump 1;

[0095] The regulating kettle 3 is stirring to adjust the pH value of the wastewater to 5, and the residence time of the wastewater is 30min. In the kettle, dimethyl disulfide is first added, and the quality of dimethyl disulfide is 0.5% of the wastewater quality, and then the adsorbent is added Powdered activated carbon, the mass of activated carbon added is 1.5% of the waste water quality. The anti-coking agent inhibits the oxidation and polymerization of aromatic organic matter in waste water to produce tar-like substances under high temperature conditions. Activated carbon absorbs and removes organic matter in waste water, thereby ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap