Quantum dot light-emitting compound used for 3D printing and preparation method thereof

A technology of quantum dot luminescence and 3D printing, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of agglomeration, strong light scattering effect, easy precipitation of phosphors and polymer colloids, etc., to achieve the effect of enhancing luminous intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0027] Example 1

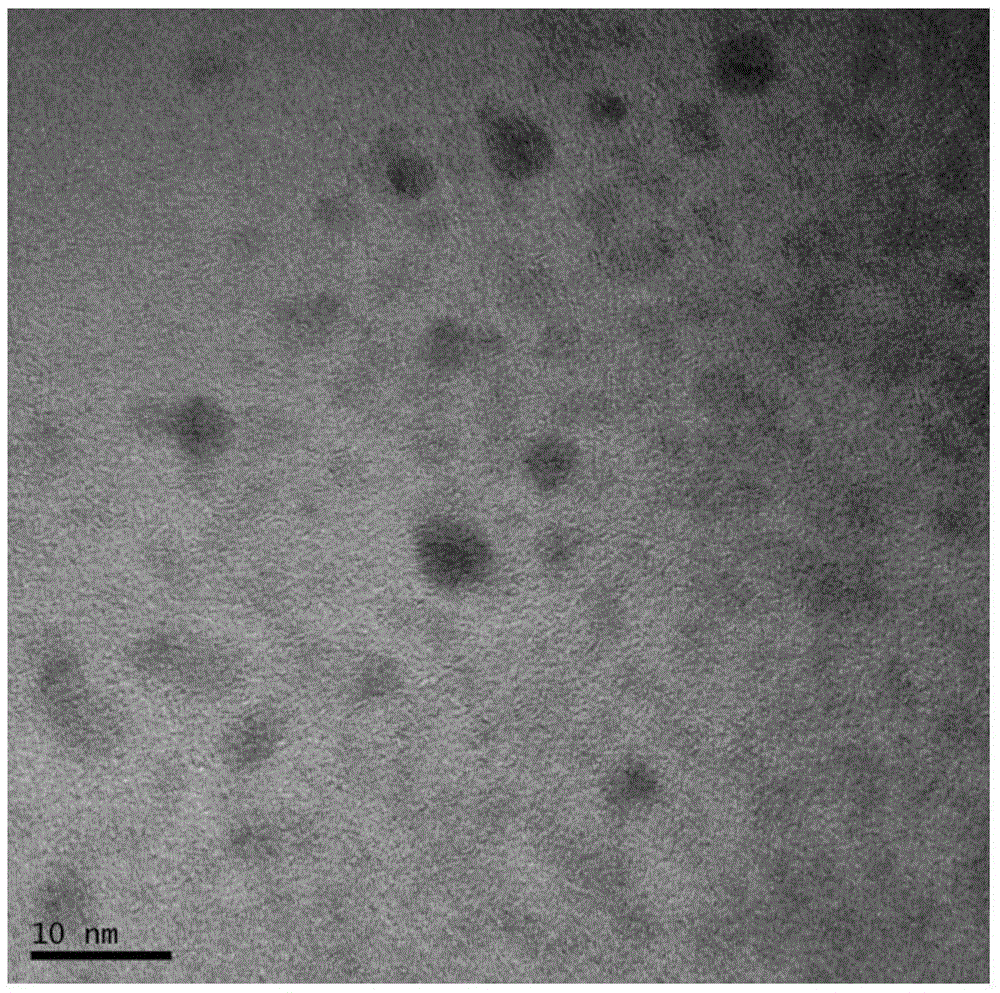

[0028] 1) Evenly mix nano-titanium dioxide, ethanol and CdZnS / ZnS quantum dots, after mixing, dry at 60° C. for 6 hours until ethanol is completely volatilized, wherein the CdZnS / ZnS quantum dots are 20 parts by mass, the nano-titanium dioxide is 10 parts by mass, and the ethanol is Excessive amount to make the nano-titania and CdZnS / ZnS quantum dots mix evenly;

[0029] 2) Put ABS resin, PLA resin, 1) the obtained mixture and benzoyl peroxide into a twin-screw extruder for melting, uniformly mix and then extrude, naturally cool, and pelletize to obtain a quanta for 3D printing. The point light-emitting compound, wherein the ABS resin is 40 parts by mass, the PLA resin is 45 parts by mass, the benzoyl peroxide is 1.3 parts by mass, the extrusion temperature is 190° C., and the screw speed is 220 rpm.

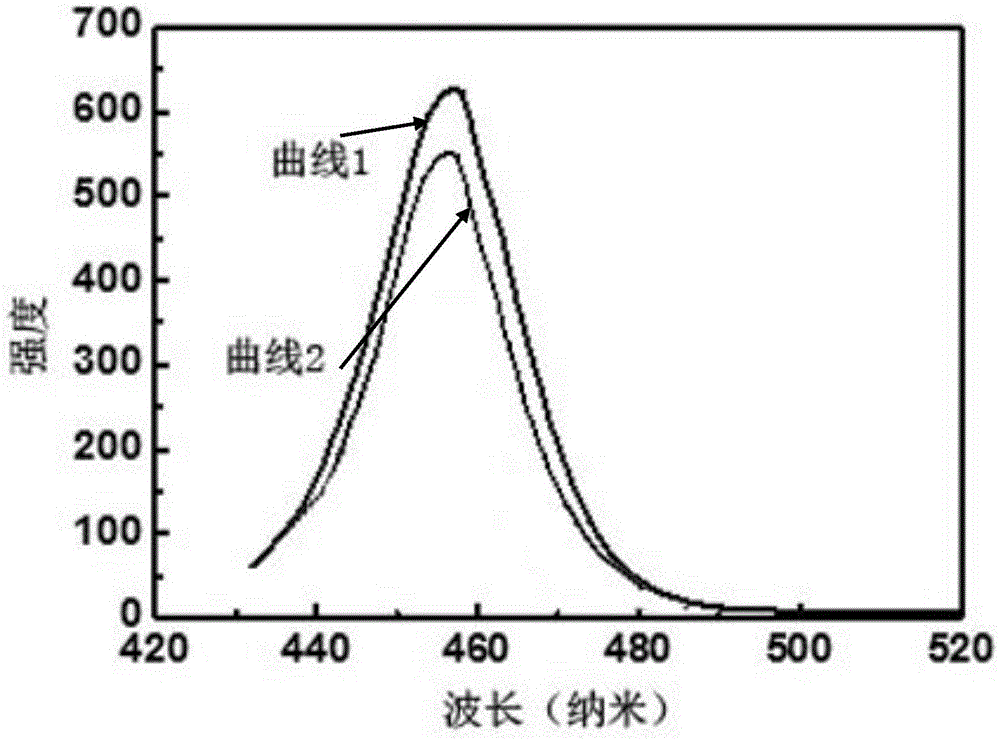

[0030] Test the emission spectrum of the quantum dot luminescent complex obtained in Example 1 according to the above test method: under the excitation of bl...

Example Embodiment

[0031] Example 2

[0032] Example 2 does not add inorganic nano-titanium dioxide compared to Example, namely:

[0033] 1) Evenly mix ethanol and CdZnS / ZnS quantum dots, and after mixing, dry at 60° C. for 6 hours until ethanol is completely volatilized, wherein the CdZnS / ZnS quantum dots are 20 parts by mass, and the amount of ethanol is excessive so that the CdZnS / ZnS quantum dots are mixed distributed;

[0034] 2) Put ABS resin, PLA resin, 1) the obtained mixture and benzoyl peroxide into a twin-screw extruder for melting, uniformly mix and then extrude, naturally cool, and pelletize to obtain a quanta for 3D printing. The point light-emitting compound, wherein the ABS resin is 40 parts by mass, the PLA resin is 45 parts by mass, the benzoyl peroxide is 1.3 parts by mass, the extrusion temperature is 190° C., and the screw speed is 220 rpm.

[0035] Test the emission spectrum of the oil-soluble quantum dot luminescent complex obtained in Example 2 according to the above-me...

Example Embodiment

[0036] Example 3

[0037] 1) Mix the nano-titanium dioxide, ethanol and CdSeS quantum dots uniformly, and dry at 70° C. for 6 hours after mixing until the ethanol is completely volatilized, wherein the CdSeS quantum dots are 35 parts by mass, the nano-titanium dioxide is 25 parts by mass, and the amount of ethanol is excessive so that the The inorganic matter and CdSeS quantum dots are mixed evenly;

[0038] 2) Put ABS resin, PLA resin, 1) the obtained mixture and dicumyl peroxide into a twin-screw extruder for melting, uniformly mix and extrude, naturally cool, and pelletize to obtain a 3D printing material. The quantum dot light-emitting compound, wherein the ABS resin is 45 parts by mass, the PLA resin is 47 parts by mass, the dicumyl peroxide is 1.9 parts by mass, the extrusion temperature is 180° C., and the screw speed is 220 rpm, that is, to obtain Quantum dot luminescent complexes for 3D printing.

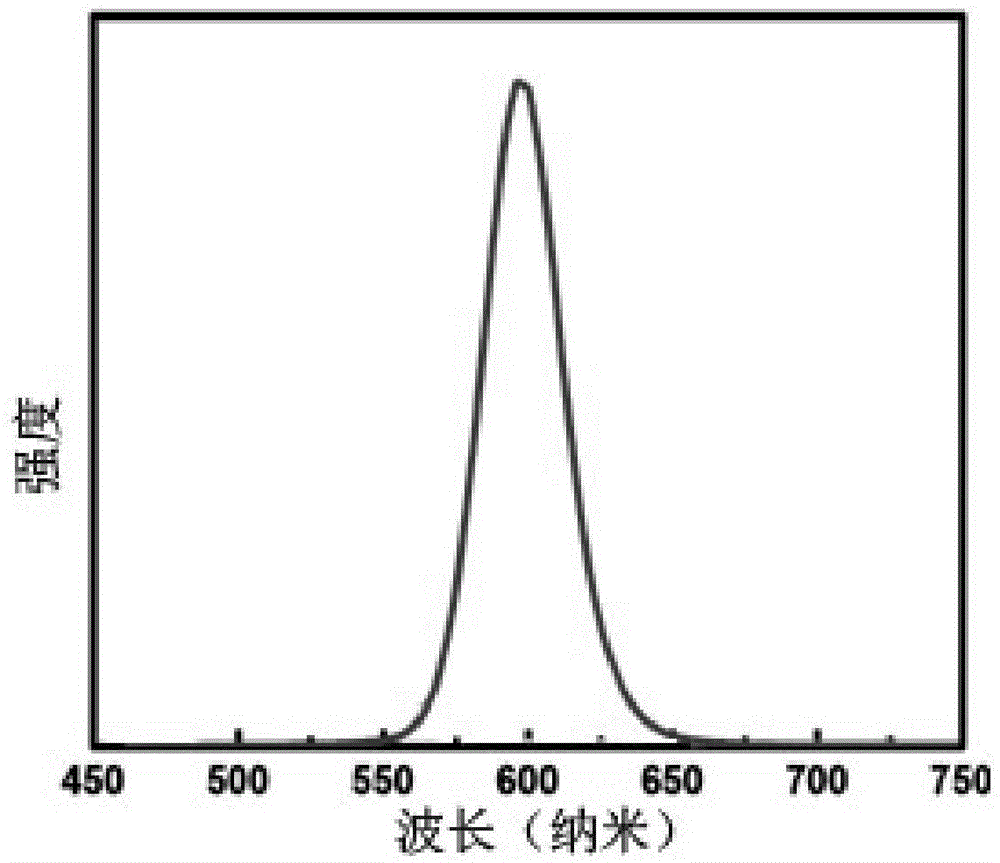

[0039] Test the emission spectrum of the quantum dot luminescent com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com