Mercerizing penetrant for cotton fabrics and preparation method thereof

A technology of mercerizing penetrating agent and cotton fabric, which is applied in plant fiber, textile, papermaking, fiber treatment, etc. It can solve the problems of volatilization of irritating gas, corrosion of pipes, impact on human health, etc., and achieves the promotion of mercerizing treatment and good penetration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

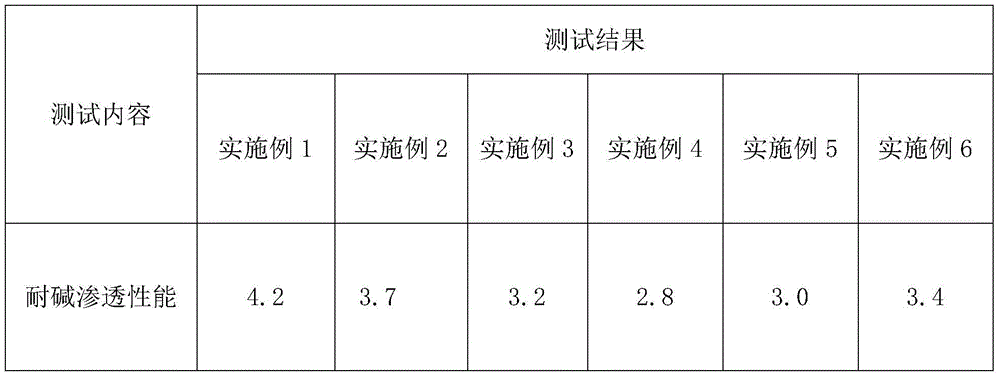

Examples

Embodiment 1

[0023] (1) Dissolve 60 parts of fatty alcohol succinate, 10 parts of sodium laurate and 5 parts of acrylic acid in a solvent, stir well, add 25 parts of emulsifier, stir and emulsify at high speed, evaporate the solvent, add 10 parts of glycerin and 25 parts deionized water, stir well;

[0024] (2) Add NaOH solution to the mixed solution produced in the previous step to adjust the pH to 7 to obtain a mercerizing penetrant for cotton fabrics.

Embodiment 2

[0026] (1) Dissolve 56 parts of fatty alcohol succinate, 18 parts of sodium laurate and 6 parts of acrylic acid in a solvent, stir evenly, add 22 parts of emulsifier, stir and emulsify at high speed, evaporate the solvent, add 8 parts of glycerin and 30 parts of deionized water, stir well;

[0027] (2) Add NaOH solution to the mixed solution produced in the previous step to adjust the pH to 7 to obtain a mercerizing penetrant for cotton fabrics.

Embodiment 3

[0029] (1) Dissolve 53 parts of fatty alcohol succinate, 12 parts of sodium laurate and 10 parts of acrylic acid in a solvent, stir evenly, add 20 parts of emulsifier, emulsify with high-speed stirring, evaporate the solvent, add 9 parts of glycerin and 15 parts deionized water, stir well;

[0030] (2) Add NaOH solution to the mixed solution produced in the previous step to adjust the pH to 7 to obtain a mercerizing penetrant for cotton fabrics.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com