A snap-ring flange connection device for assembled inner support of foundation pit

A connecting device and prefabricated technology, which is used in infrastructure engineering, excavation, construction, etc., to achieve the effect of speeding up assembly, saving erection time, and reducing deformation of foundation pits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

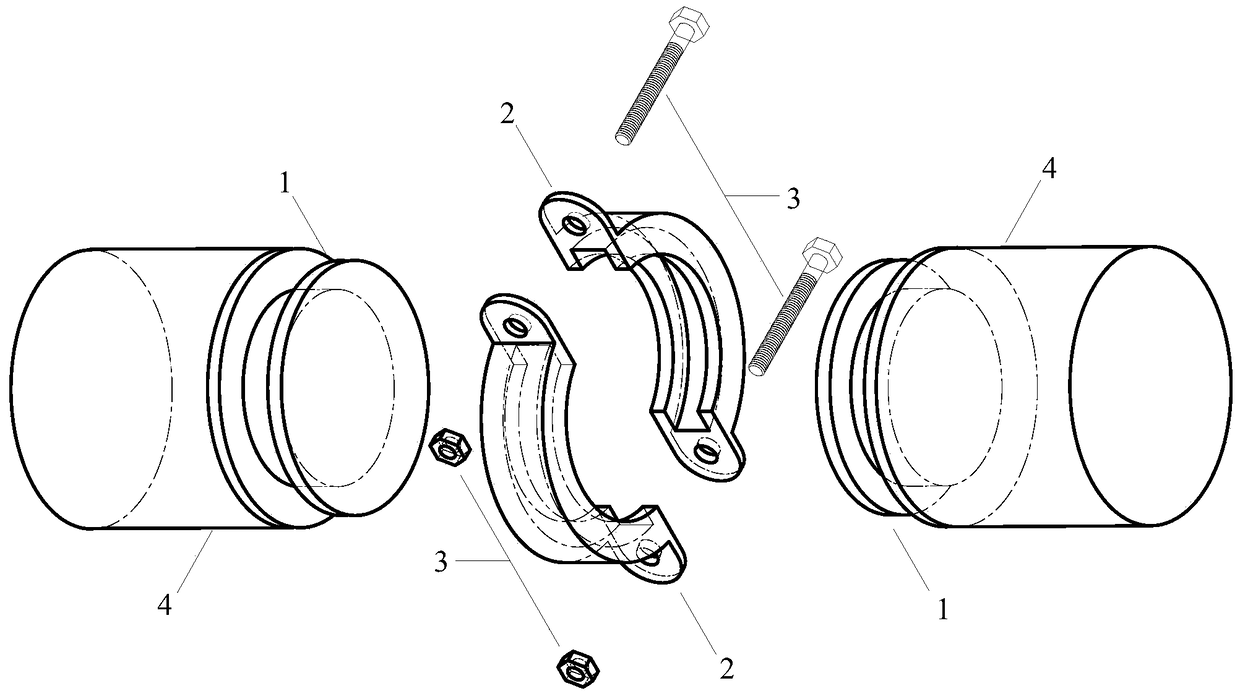

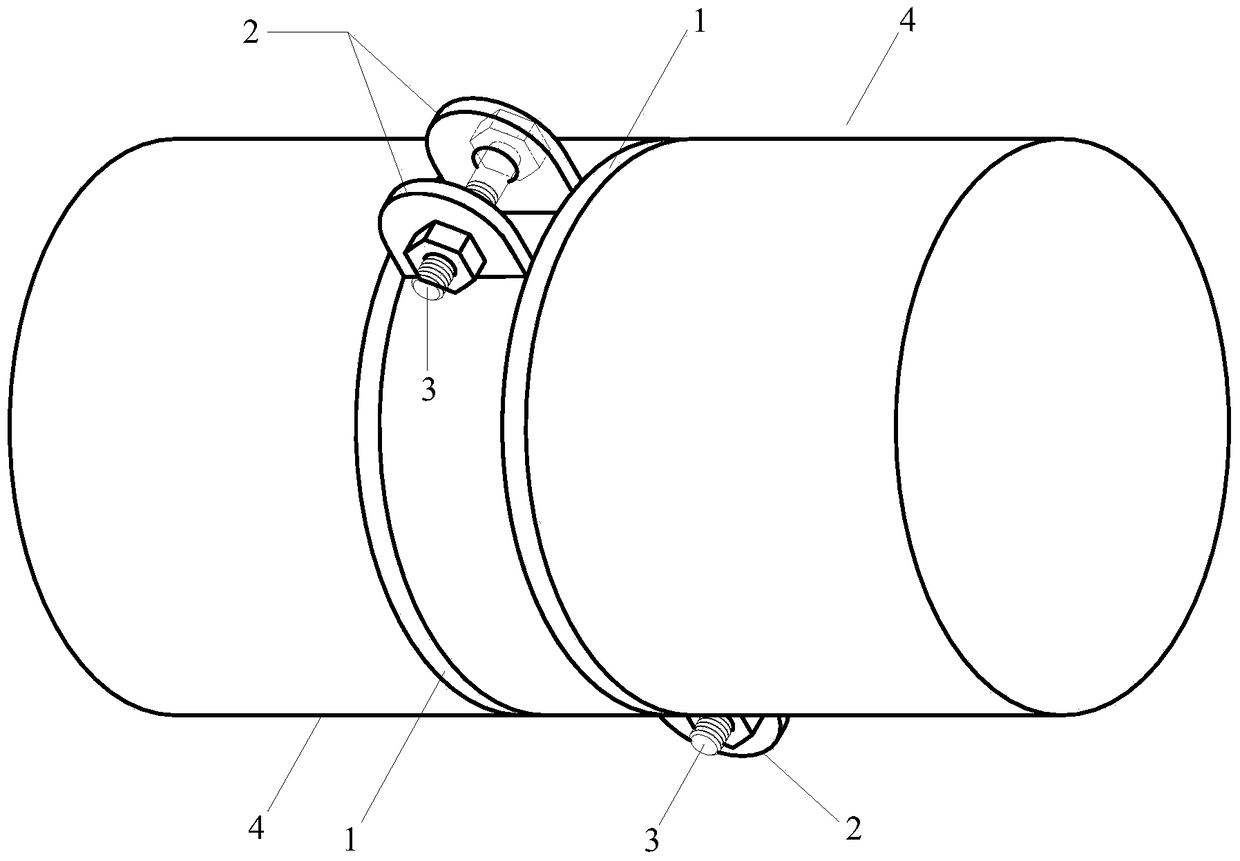

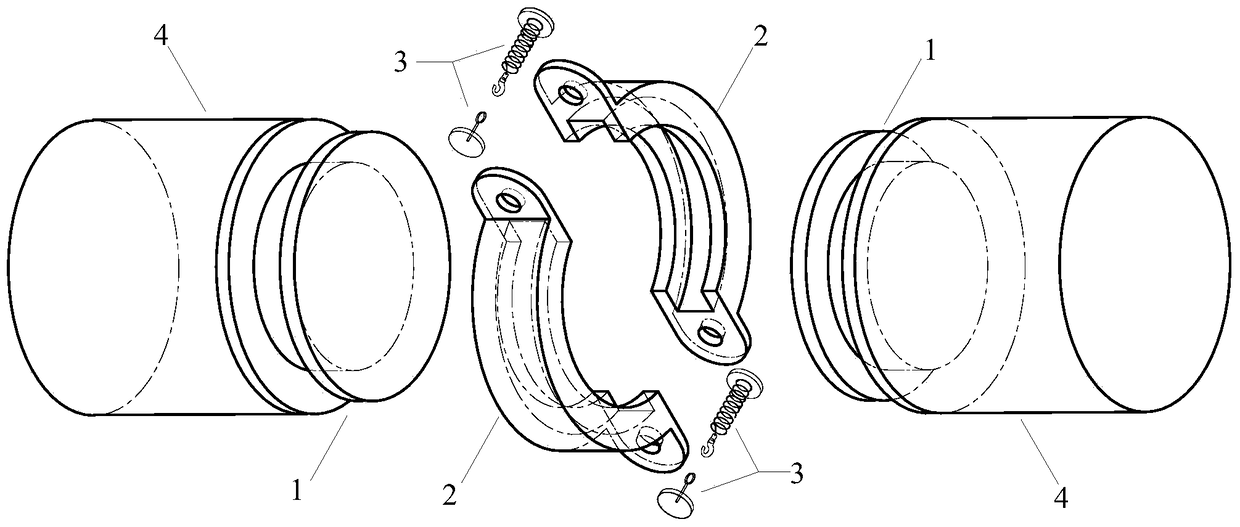

[0031] The installation steps of the present invention and the principle of action between the components are as follows:

[0032] Firstly, one surface of the bevel flange (1) is fixed to the end part (4) of the support member, and the other surface is closely attached to the surface (1) of the other bevel flange.

[0033] Then, a piece of rubber pad is hooped on the groove flange (1) to avoid stress concentration on the contact surface of the groove flange (1) and the snap ring type splint (2), and prevent surface wear caused by rigid contact.

[0034] Then, buckle the two grooved flanges (1) along the ring direction with a snap ring splint (2). The bevel angle of the bevel flange (1) is equal to the inner angle of the groove of the clasp type splint, and the two are closely attached and extruded on the contact surface, thereby producing the effect of fastening and strengthening.

[0035] Finally, the fastener (3) penetrates the bolt hole (10) of the snap ring splint (2), pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com