Attitude detection method of large liquefied natural gas module based on 3D laser detection

A technology of liquefied natural gas and three-dimensional laser is applied in the field of attitude detection of large-scale liquefied natural gas modules, which can solve the problems of low precision and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in combination with specific embodiments.

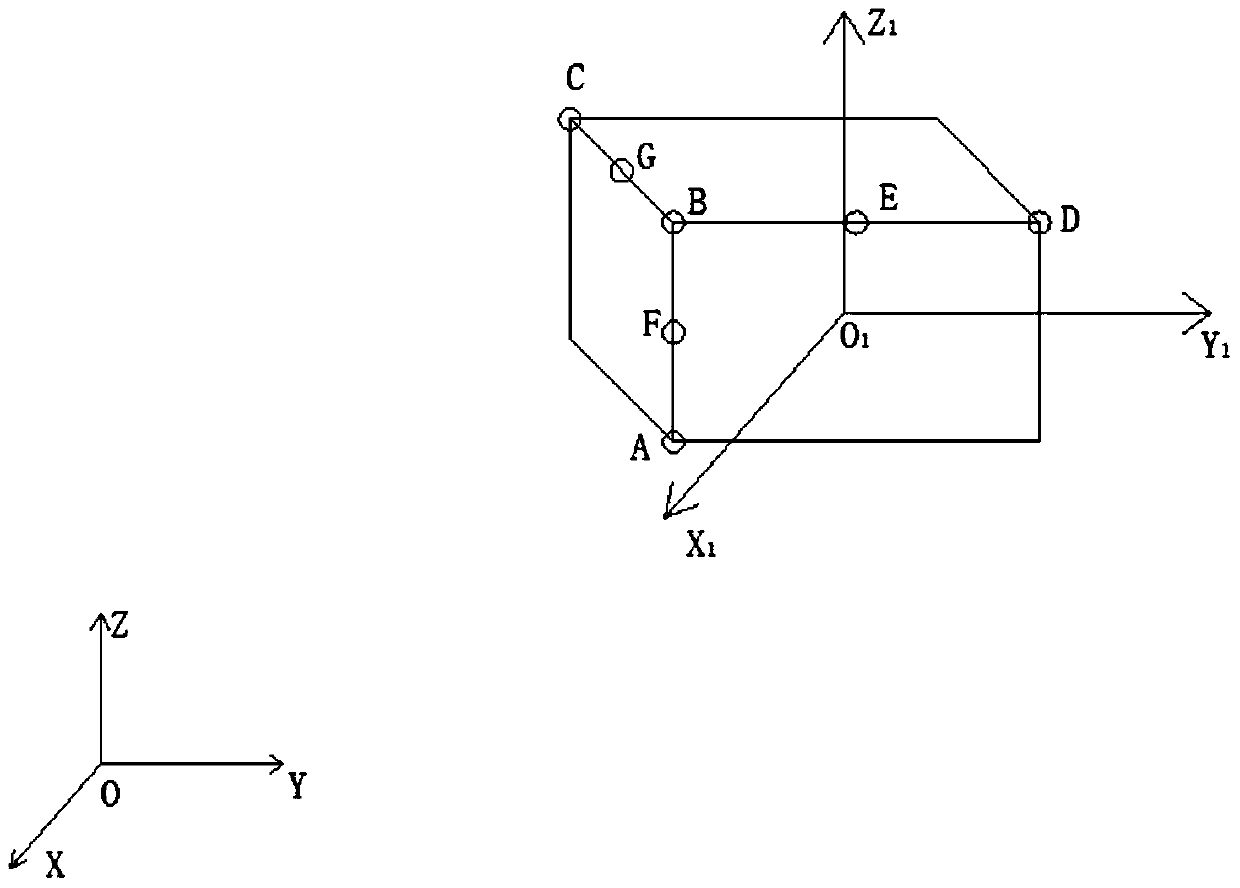

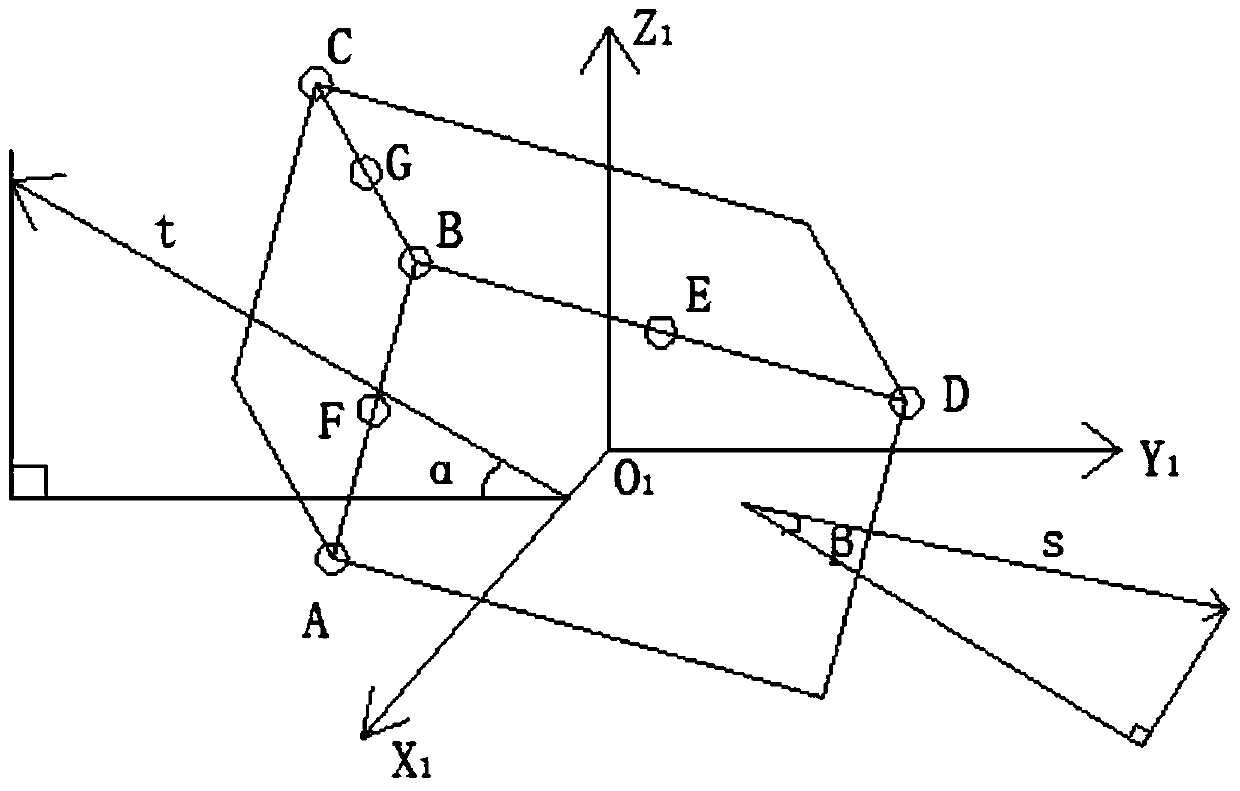

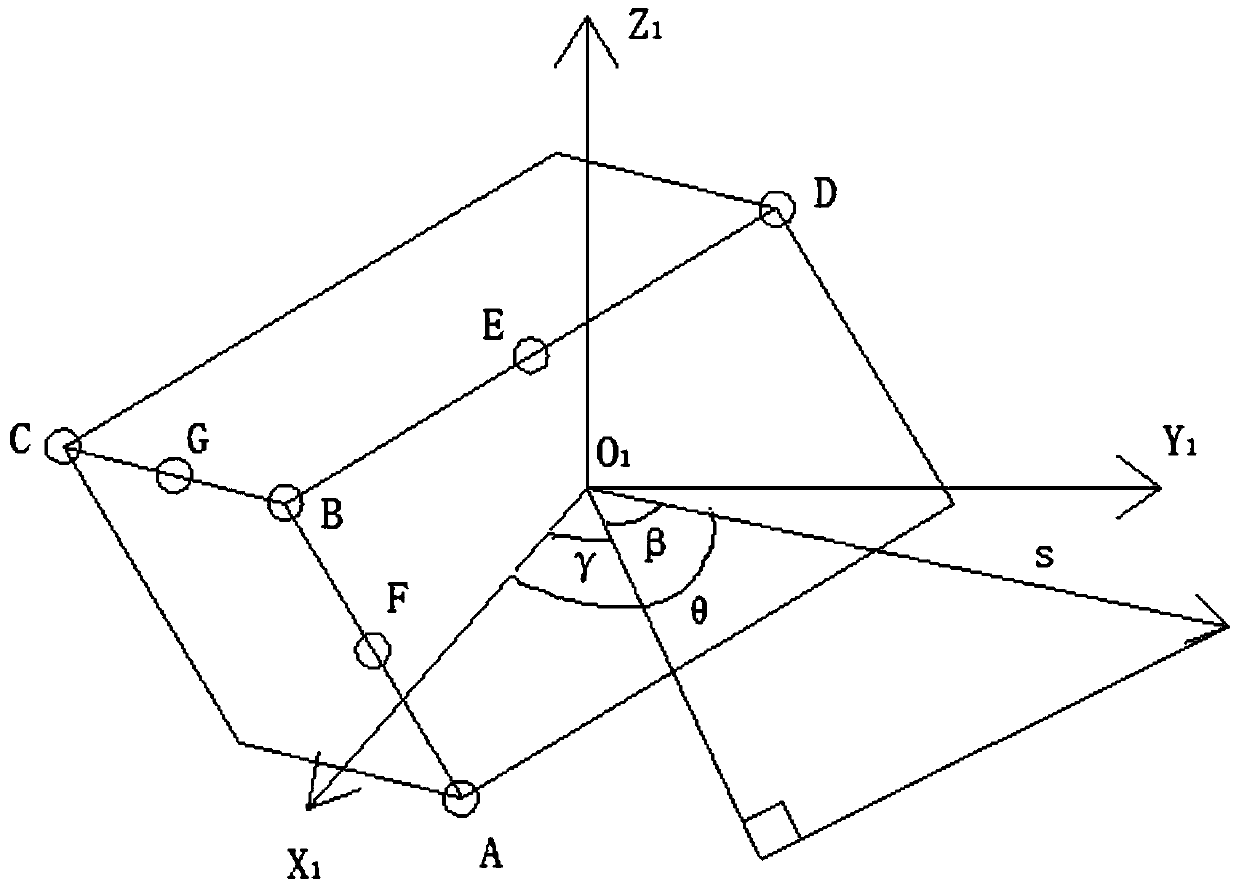

[0020] As shown in the accompanying drawing, the large-scale liquefied natural gas module attitude detection method based on three-dimensional laser detection includes the following steps:

[0021] (1) In the CAD drawing and on the construction site, set one of the two modules to be connected as the reference module and the other module as the module to be connected. The reference module does not move, and drag it in the CAD drawing Move the datum module, so that the coordinate value of the datum module in the CAD drawing is consistent with the coordinate value of the datum module in the construction site;

[0022] (2) Select 7 measurement points respectively at the same position on the CAD drawing and the module to be connected at the construction site, and the 7 measurement points are respectively the four corner points of the three boundary lines of the module to be conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com