Adaptive adjusting method for material production

A self-adaptive adjustment and material technology, applied in the control/regulation system, sequence/logic controller, program control, instruments, etc. The effect of ensuring traceability, improving production efficiency and reducing defective rate

Active Publication Date: 2016-05-25

BOZHON PRECISION IND TECH CO LTD

View PDF11 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the traditional automated production line, machines replace manual labor to achieve automation and automatically produce products. However, when the defective rate of production materials is relatively high, the problem can only be analyzed and processed manually, and intelligent adaptive adjustment cannot be achieved, which reduces production efficiency and quality.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

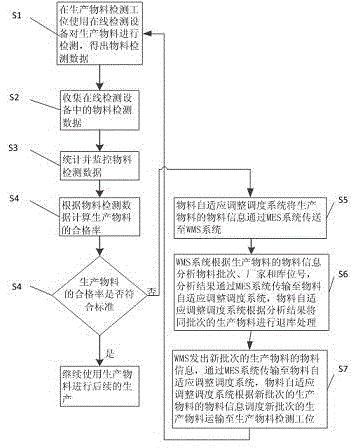

[0024] like figure 1 As shown, a method for adaptive adjustment of production materials in this embodiment includes the following steps:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention reveals an adaptive adjusting method for material production, and the method can detect and monitor material detection data of material production in real time. When an abnormality is monitored to happen in material production, abnormal data is automatically uploaded to an upper computer for analysis, and the method carries out automatic withdrawal from a database, and dispatches production materials of a new batch. The beneficial effects of the invention are as follows: 1, the method does not need manual operation, can adaptively dispatch the production materials, and achieves the intelligentization of a production system; 2, the method can inspect the abnormal conditions timely, guarantees the normal operation of production, reduces the reject ratio, improves the quality of products, and improves the production efficiency; 3, the method guarantees the traceability of information, and achieves the informatization of the production system.

Description

technical field [0001] The invention belongs to the technical field of production automation, in particular to an adaptive adjustment method for production materials. Background technique [0002] With the proposal of Made in China 2025, the traditional manufacturing industry has been promoted to develop in the direction of intelligent information production. In the traditional automated production line, machines replace manual labor to achieve automation and produce products automatically. However, when the defect rate of production materials is relatively high, the problem can only be analyzed and processed manually, and intelligent adaptive adjustment cannot be achieved, which reduces the efficiency and quality of production. [0003] MES is the abbreviation of manufacturing execution system (manufacturing execution system). Process production information management and data processing, including order data release, production instruction data release, production process...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G05B19/05

CPCG05B19/05G05B2219/25268

Inventor 吕绍林杨愉强徐小武吕文昌时伟生高俊汪丽群

Owner BOZHON PRECISION IND TECH CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com