Aqueous solution dispersion system temperature control system based on ammonium nitrate precipitation

A temperature control system, ammonium nitrate technology, applied in the direction of temperature control without auxiliary power supply, can solve the problems of complex technology, high metal cost, poor cooling effect, etc., to achieve the effect of speeding up the recovery rate and strengthening market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

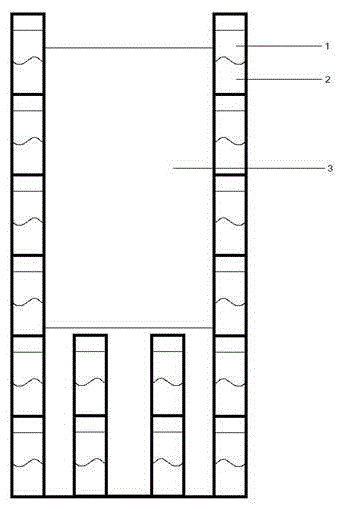

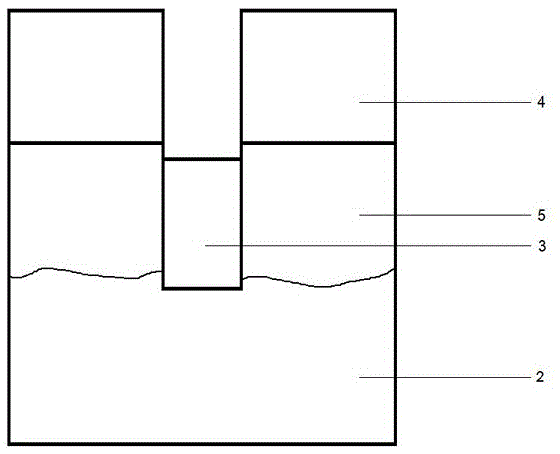

[0032] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

[0033] The invention discloses a temperature control system based on an aqueous solution dispersion system of ammonium nitrate precipitation, which comprises a temperature control fluid, a storage module and a heat exchange module;

[0034] The temperature control fluid is an aqueous dispersion containing ammonium nitrate precipitate;

[0035] The storage module is used to store temperature control fluid;

[0036] The heat exchange module is made of a material with good thermal conductivity, and is used to place objects that need to be controlled in temperature to exchange heat with the temperature control fluid.

[0037] The storage module adopts a material resistant to the acid-base environment of the temperature-control fluid as the outer wall.

[0038] The heat exchange module can be a cavity arranged on the storage module, or it can be arran...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap