Precise calculation method for winding stator mode of AC (alternating current) motor

A technology of AC motors and calculation methods, applied in calculation, electrical digital data processing, design optimization/simulation, etc., to achieve the effects of high calculation accuracy, improved accuracy, and accurate axial modal calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the purpose, technical solutions and advantages of the present invention more understandable, the present invention will be further described in detail in conjunction with specific examples.

[0031] In the present invention, in order to test and analyze the modal parameters of the winding stator, the winding stator of the motor is selected, and the modal test is carried out in the following manner;

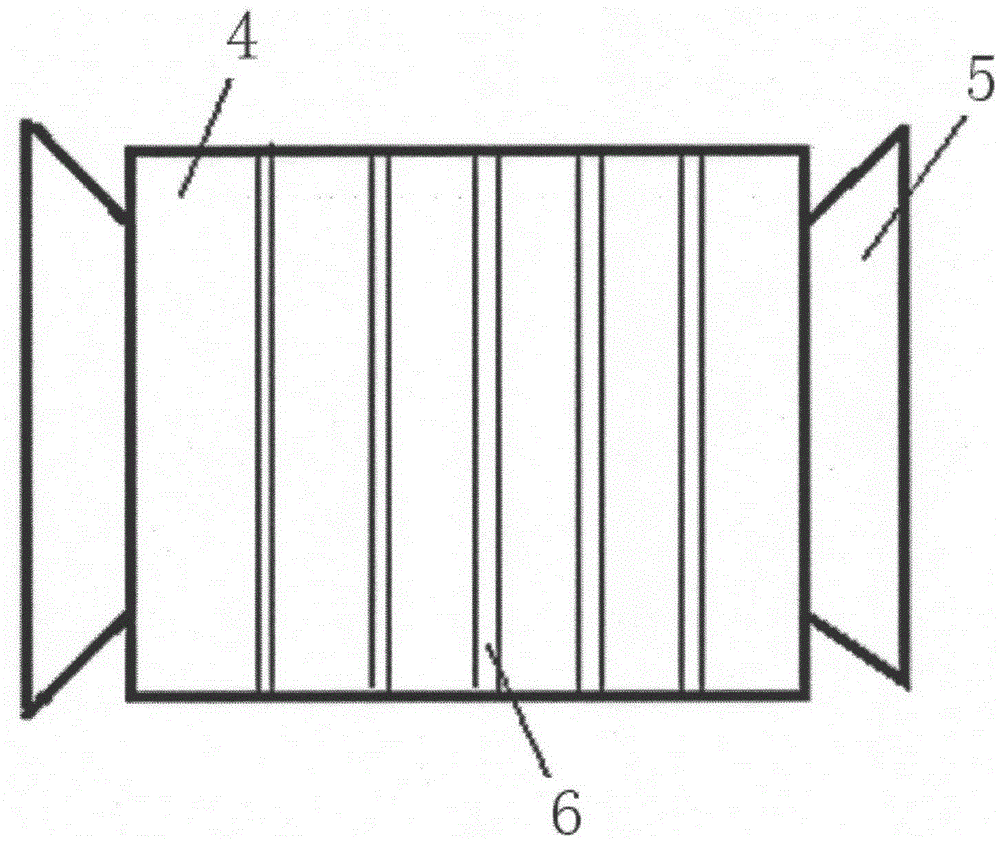

[0032] 1) Select the actual product of the stator with windings. The product includes a stator core composed of silicon steel sheets, a coil wound by copper wires, slot insulation, winding insulation and insulating varnish;

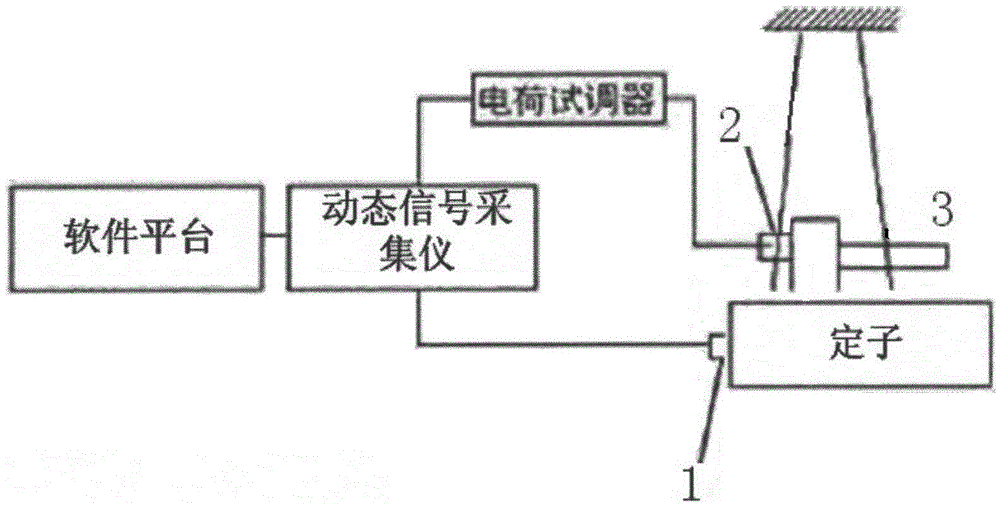

[0033] 2) Carry out modal test on the selected winding stator. Such as figure 1 As shown, the modal test will have a winding stator using springs and nylon ropes to suspend the stator in the air. Divide the outer surface of the stator into 8 equal parts along the circumferential direction, and each equal part distributes 3 measurin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com