Multifunctional vacuum impregnating equipment

A vacuum immersion and multi-functional technology, applied to electrical components, insulators, circuits, etc., can solve the problems of uncontrollable oil immersion speed, unsatisfactory oil immersion method, and failure to heat the oil tank, etc., to achieve controllable oil immersion flow rate and oil discharge The process is gentle and realizes the effect of low liquid level alarm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

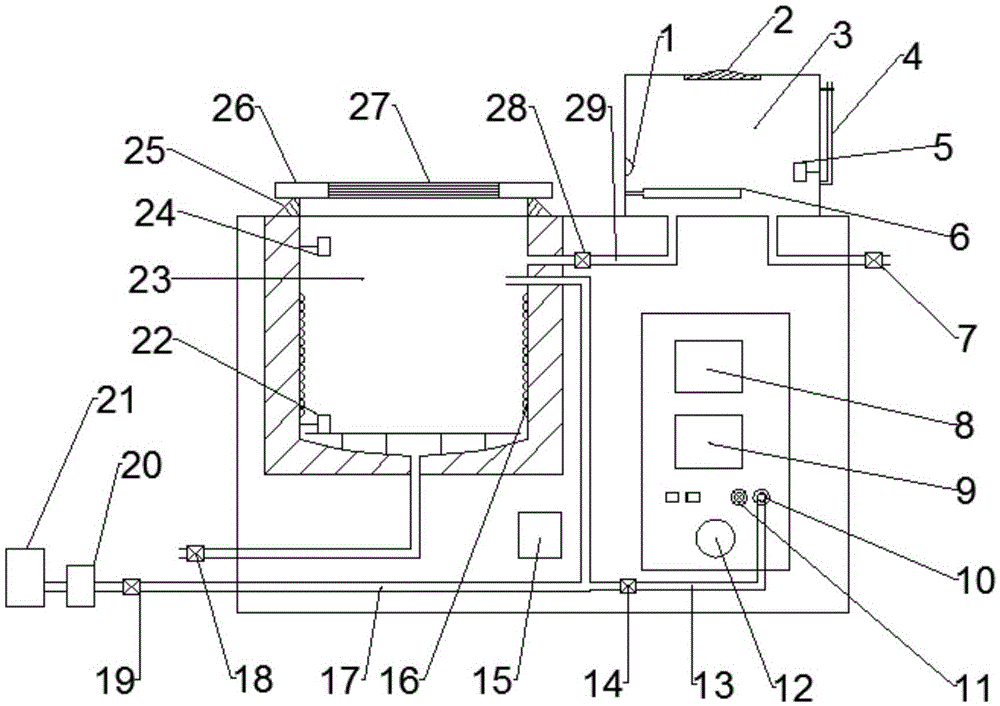

[0024]This experiment is an example of vacuum drying. The heating temperature range of the vacuum tank 23: RT+10-150°C, the heating temperature range of the oil tank 3: RT+10-150°C, the temperature fluctuation: ±1°C, the vacuum degree of the vacuum tank 23≤133Pa , the size of the vacuum tank 23 is φ500×450mm, prepare 20 pieces of insulating cardboard to be dried before the experiment, the thickness of the insulating cardboard is 2mm, and the diameter is 150mm. Put the oil valve 28 and the inflation valve 14 on, put the insulating cardboard to be dried into the vacuum tank 23, close the sealing cover 26, press the sealing gasket 25, and make the vacuum tank 23 completely sealed. Turn on the main power switch and the vacuum switch, set the vacuum degree on the vacuum instrument 12 to -90KPa, the vacuum pump 21 starts to work, and detect the pressure difference between the air pressure in the vacuum tank 23 and the atmospheric pressure through the pressure sensor 22 in the vacuum ...

Embodiment 2

[0026] This experiment is a vacuum drying oil immersion experiment: vacuum tank 23 heating temperature range: RT+10-150°C, oil tank 3 heating temperature range: RT+10-150°C, temperature fluctuation: ±1°C, vacuum tank 23 The vacuum degree is ≤133Pa, the size of the vacuum tank 23 is φ500×450mm, 20 pieces of insulating cardboard to be dried before the experiment, the thickness of the insulating cardboard is 2mm, the diameter is 150mm, a high temperature and corrosion resistant aging tank, and the insulating cardboard sample is put into the aging tank , an appropriate amount of oil sample. First close the oil discharge valve 18 on the discharge pipe at the bottom of the vacuum tank, the oil discharge valve 28 on the connecting pipe 29 connected to the fuel tank 3, and the inflation valve 14, put the aging tank with insulating cardboard to be dried into the vacuum tank 23, close the seal The cover 26 is pressed into the sealing gasket 25 to completely seal the vacuum tank 23, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com