Waterproof patched elastic key

A patch type, button technology, applied in electrical components, electrical switches, circuits, etc., can solve problems such as inapplicability and inability to meet high-density application requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

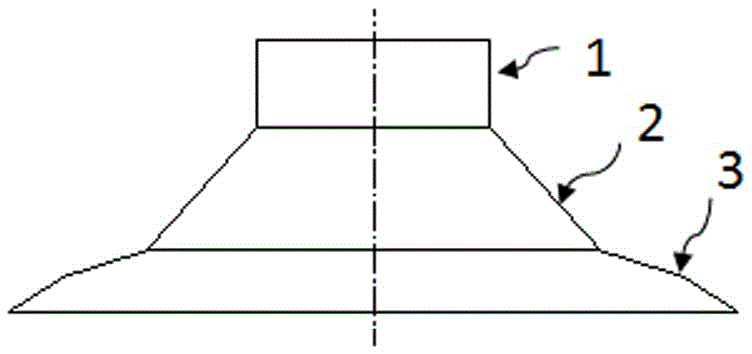

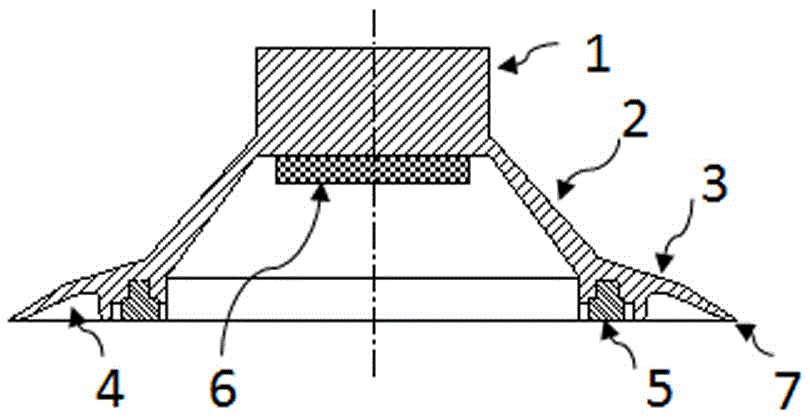

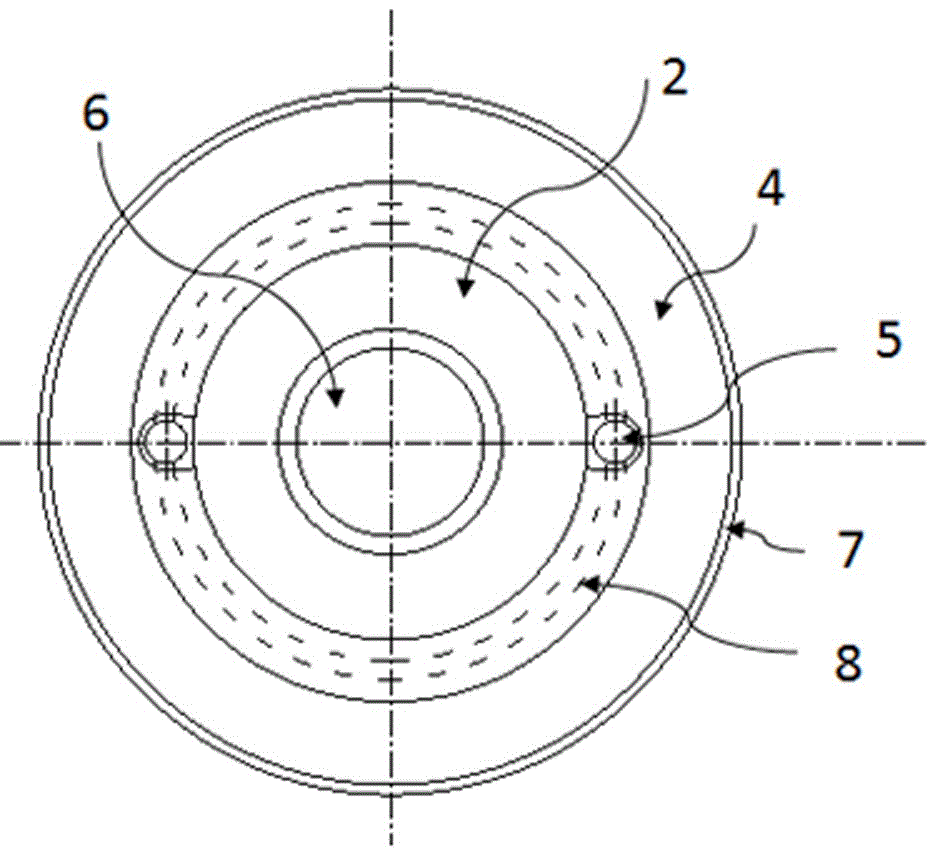

[0026] See Figure 1-4 , A waterproof patch type flexible button, including a base 3 and button software, the button software includes a button convex body 1, flexible software 2 and conductive contacts 6, the flexible software 2 is in the shape of a conical cylinder, the flexible software The inner edge of the small mouth of 2 is connected with the key convex body 1, the large mouth end of the elastic software 2 is connected with the upper surface of the base 3, and the middle of the base 3 has a through hole corresponding to the large mouth end of the elastic software 2, and the conductive contact 6 is provided On the lower end surface of the key convex body 1, the outer side of the base 3 is provided with a waterproof soft side 7, and at least one waterproof cavity 4 is provided in the waterproof soft side 7.

[0027] The bottom of the base 3 is provided with a built-in welding foot 5 protruding downward, the built-in welding foot 5 is not exposed outside the base 3, the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com