Manufacture method adopting inner layer pattern transfer exposure

A production method and technology of inner layer graphics, applied in the direction of pattern and photolithography, multilayer circuit manufacturing, pattern formation through transfer, etc., can solve the problems of scrapping the whole board, misalignment between the graphics layers on both sides, etc., and achieve convenient and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical features of the present invention will be described in further detail below in conjunction with the accompanying drawings so that those skilled in the art can understand.

[0025] A method for making an inner layer graphic transfer exposure, comprising the following steps:

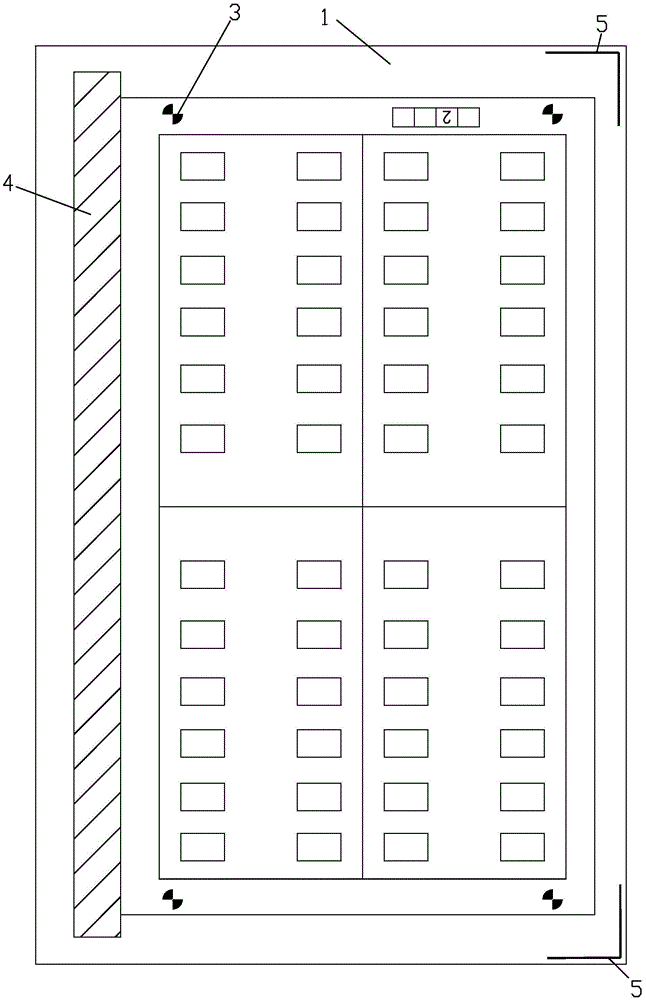

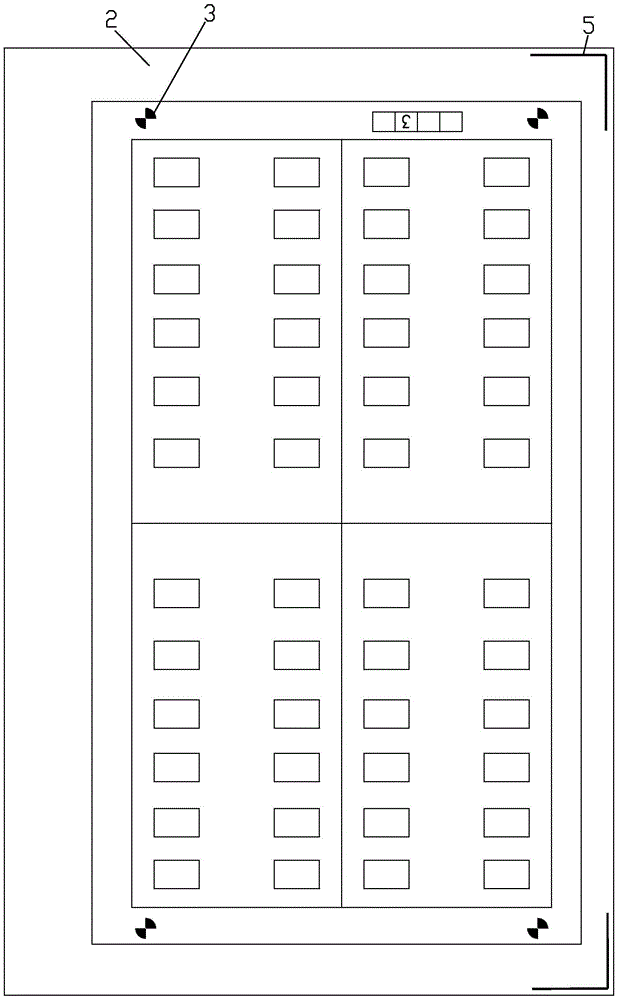

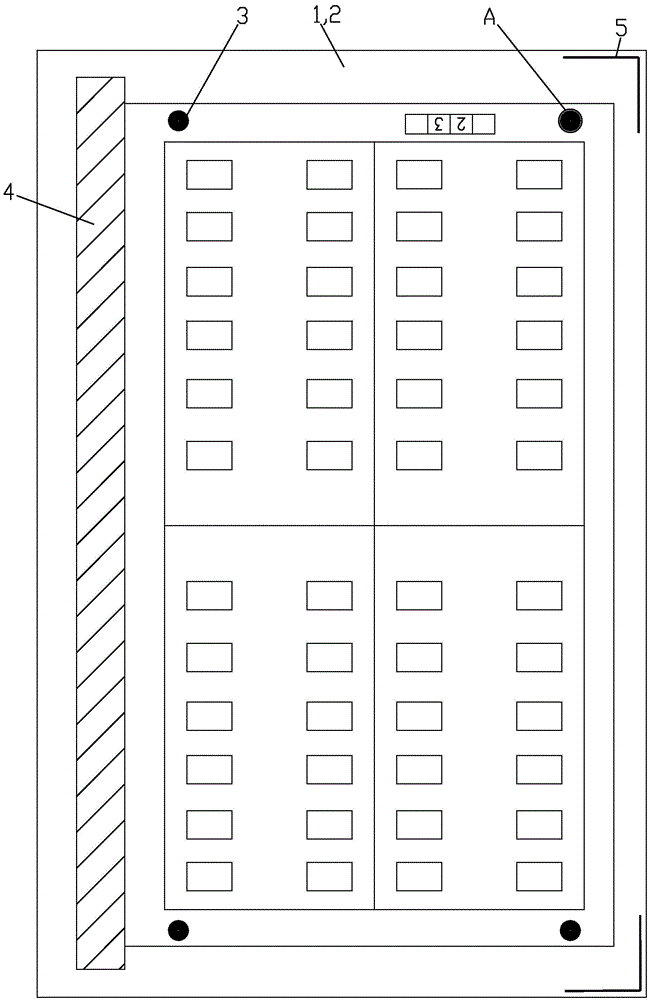

[0026] A. Film production, use CAM to design two films: the lower film 1 and the upper film 2, the circuit board to be exposed is sandwiched between the two films for exposure, and at least three corners of the effective area of the two-sided exposure film are added respectively. Butterfly-shaped PAD3, said butterfly-shaped PAD3 is an image developed on a film;

[0027] B. Carry out film "sandwich" production: stick the bottom of the auxiliary side strip 4 to the periphery of the lower film 1 through double-sided adhesive tape, and stick double-sided adhesive tape on the top of the auxiliary side strip 4;

[0028] C. Align the upper film 2 with the lower film 1 until the correspondi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com