Device for suctioning off waste products from production machine

A kind of equipment and machine technology, which is applied in the field of suction production machines, can solve problems such as interference geometry, blockage, and unreliable suction of waste products, and achieve the effect of avoiding blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

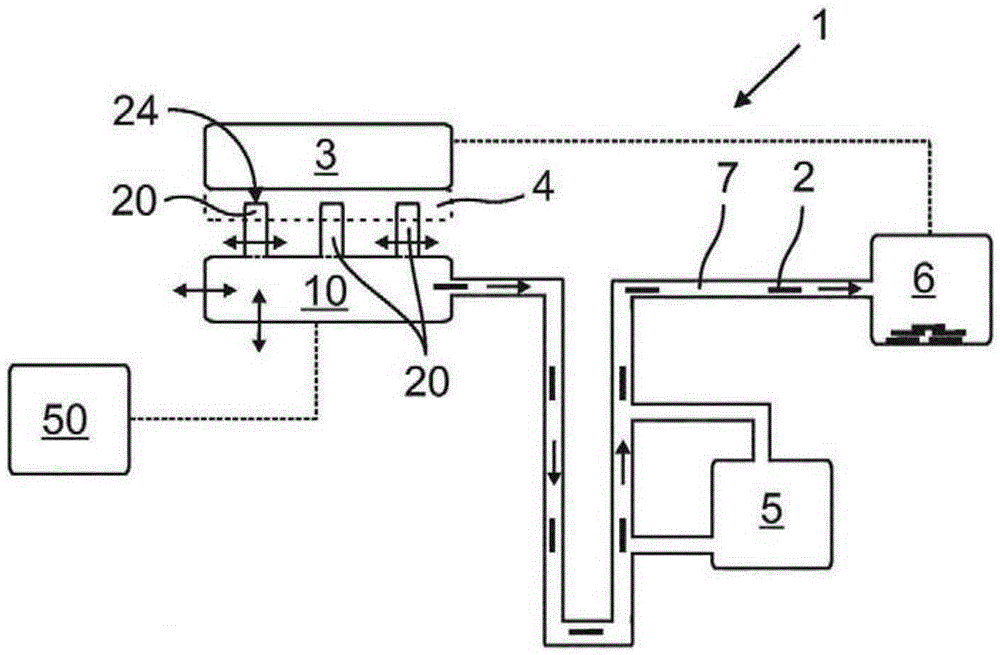

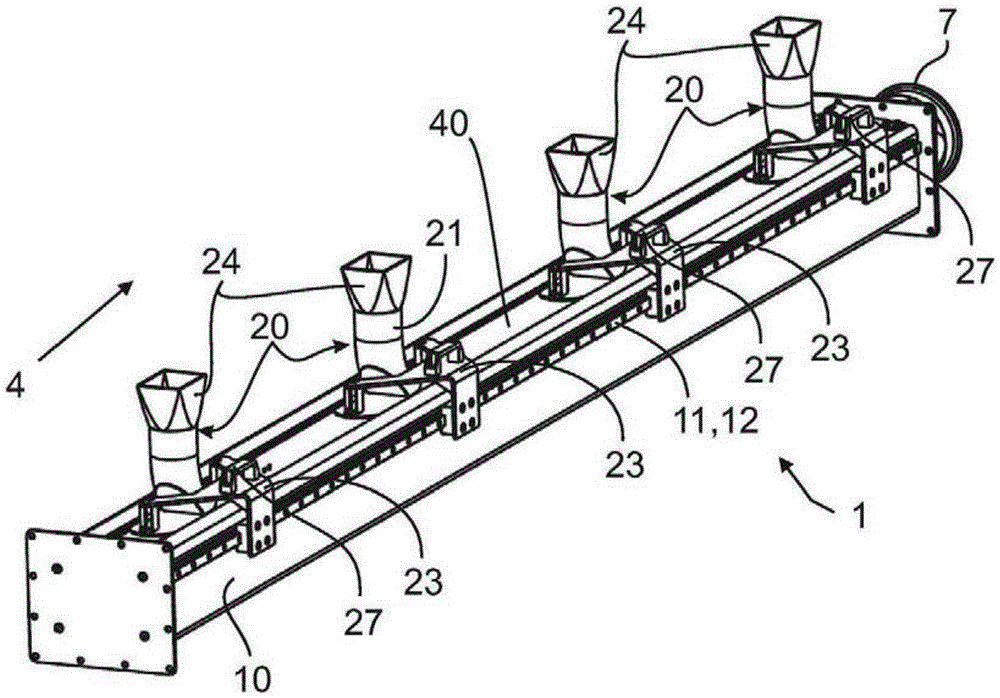

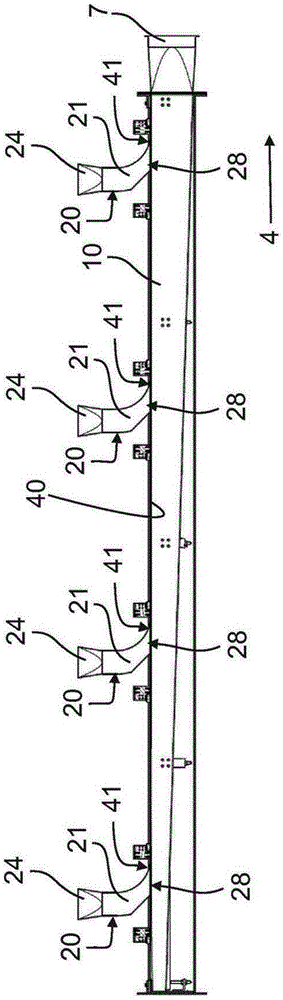

[0048] figure 1 A device 1 for suctioning off waste products 2 of a production machine 3 is shown. The production machine 3 may be a machine for the manufacture of flexible packaging elements, in which waste products 2 occur during production, from which waste products 2 are to be removed, because otherwise they may be produced during production or in the production machine 3 Unexpected interference during operation. The production machines 3 may be blown and cast film equipment, flexographic and gravure printing presses, machines for refining and treating paper, film and plastic fabrics, or packaging machines. The waste product 2 can consist of plastic or paper. Here, the surface properties of the waste product 2 may vary. For example, it is conceivable that the waste product 2 is sticky and / or matte and / or smooth.

[0049] For the purposeful removal of these waste products 2 from the region of the production machine 3 , a device 1 for suctioning out the waste products 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com