Oil supply type compressor

一种压缩机、供油的技术,应用在旋转活塞式机械、机械设备、机器/发动机等方向,能够解决电动机负担增大、压缩空气供给量不足等问题,达到避免起动迟滞、缩短压力降低时间的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

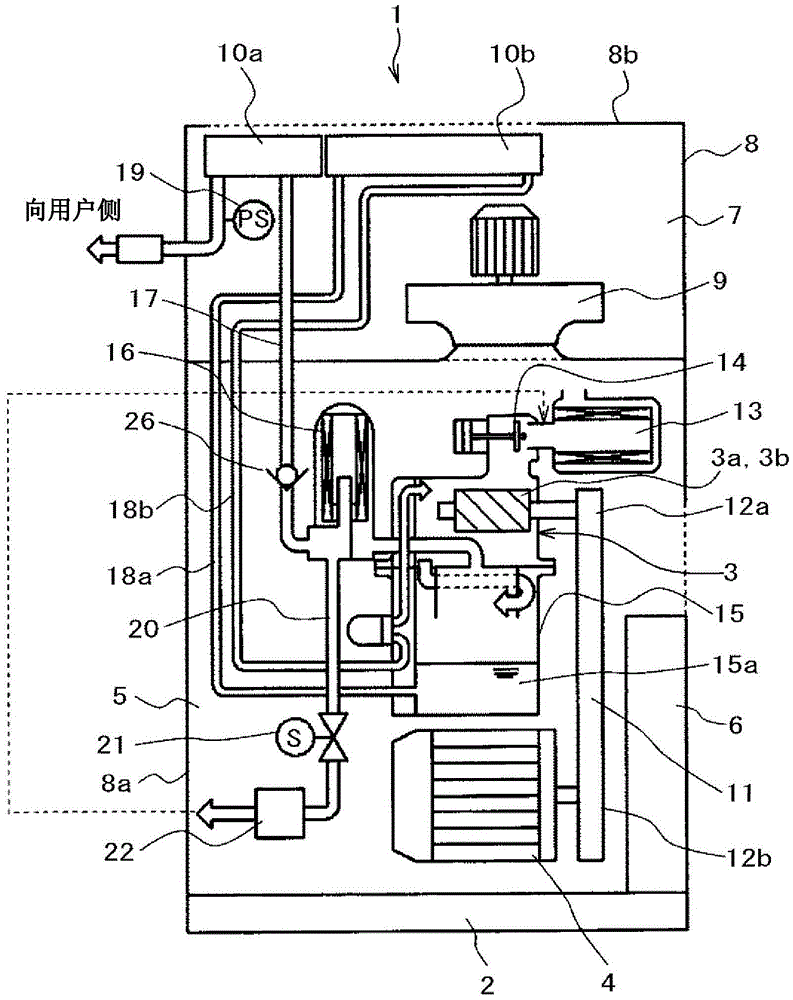

[0041] For the embodiment 1 of the oil-supply compressor of the present invention, take the situation applied to the oil-supply screw compressor as an example, use Figure 1 ~ Figure 4 Be explained.

[0042] according to figure 1 , to describe the overall structure of the oil-supplied screw compressor of the first embodiment.

[0043] figure 1 The illustrated oil-supply screw compressor (hereinafter also simply referred to as a compressor) 1 is a device for producing compressed air, and is configured as a package type. This package type oil supply type screw compressor 1 has a base 2 as a base and a package 8 provided on the base 2 , and the inside of the package 8 is divided into a lower machine room 5 and an upper cooling room 7 . The package 8 is constituted by soundproof covers 8a, 8b for suppressing the propagation of noise to the outside of the machine.

[0044] In the above-mentioned machine room 5, a compressor main body 3 for producing compressed air, a motor 4 fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com