Automatic steel bar feeding device and cutting-off machine

An automatic feeding and bar material technology used in cutting devices and cutting machines. ,Feeding device, in the field of automatic steel bar feeding device, it can solve the problems of inability to use cutting machine, surface damage of steel bar, high labor intensity, etc., to avoid scratches on the surface of steel bar, high shear force, and increase the number of shears.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

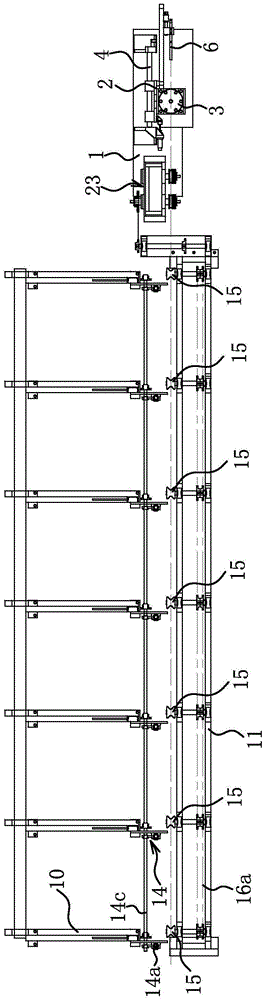

[0027] The steel bar automatic feeding device comprises a bar storage rack 10 and a bar delivery rack 11 .

[0028] The bar stock storage rack 10 has a material placing platform 10a arranged obliquely. The bar storage rack 10 includes a storage base frame 10b and a bar bracket 10c; the upper surface of the bar bracket 10c is an adjustable inclination angle of the material placing table 10a. One side edge of the bar bracket 10c is hinged to the storage base 10b, and the other side of the bar bracket 10c is connected to the storage base 10b through multiple sets of screw lifters 10d; specifically , the body of the screw lifter 10d is hinged with the storage base frame 10b, and the screw mandrel of the screw lifter 10d is hi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap