Metal circular saws for sawing small cross-sections of finished steel

A technology of metal discs and small cross-sections, which is applied to metal sawing equipment, metal processing equipment, metal processing machinery parts, etc., can solve the problems of affecting the precision of finished products, large vibration of equipment, and low sawing efficiency, so as to improve sawing efficiency. Accuracy, improved production efficiency, good clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

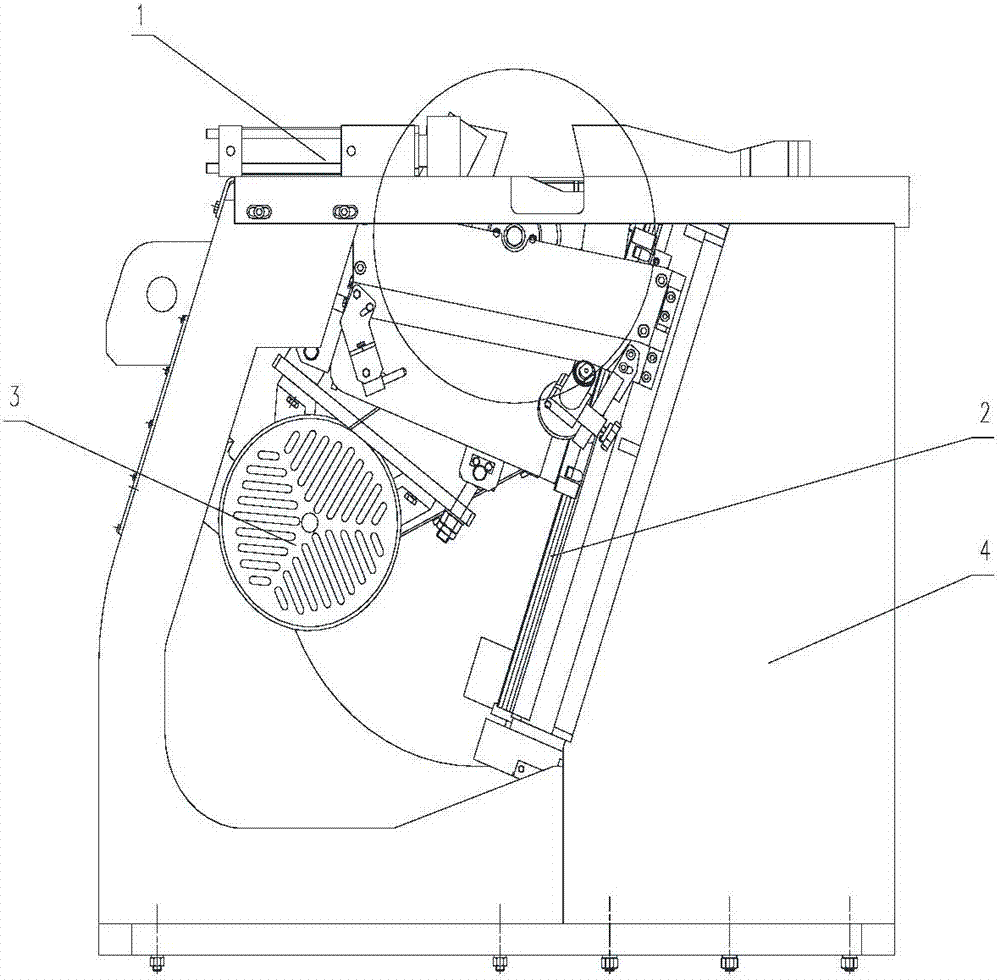

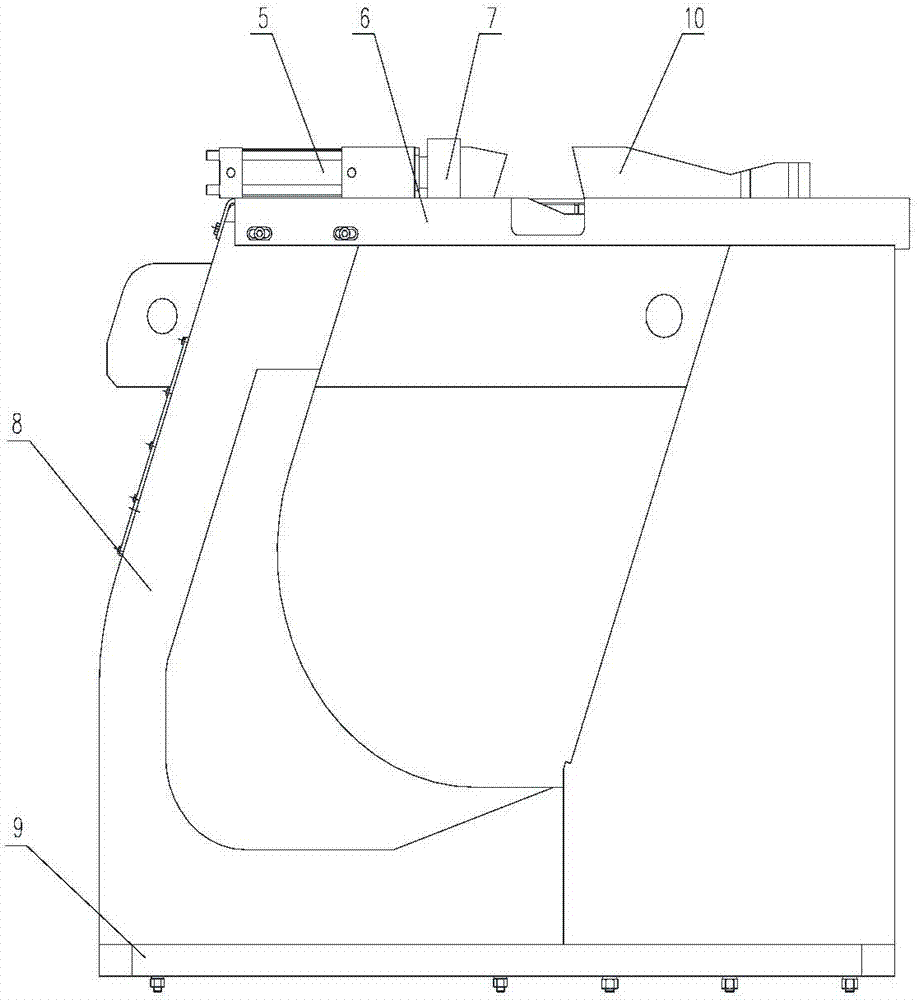

[0030] Such as Figure 1-5 As shown, the metal circular saw for sawing small-section finished steel products in this embodiment mainly includes a box-type frame, and the box-type frame includes a first support 8 and a second support 4 that are oppositely arranged. Both ends of the support 8 and the second support 4 are respectively connected to the second base 9 through the first bottom plate 6, the first support 8 is spliced with the bottom end surface of the second support 4, and the Above the bottom end surface of the first support 8 and the second support 4 forms a space for installing the saw head feeding device 2 and the saw head assembly device 3 , and the table clamping device 1 is fixedly connected to the first bottom plate 6 .

[0031] Wherein, the table clamping device 1 includes a clamping hydraulic cylinder 5; the clamping hydraulic cylinder 5 is fixed on one side of the upper end surface of the first bottom plate 6, and the piston rod end of the clamping hydra...

Embodiment 2

[0040] In the second embodiment, the metal circular saw for sawing small-section finished steel is based on the first embodiment, and a plurality of saw blade clamping parts are arranged symmetrically on both sides of the saw blade.

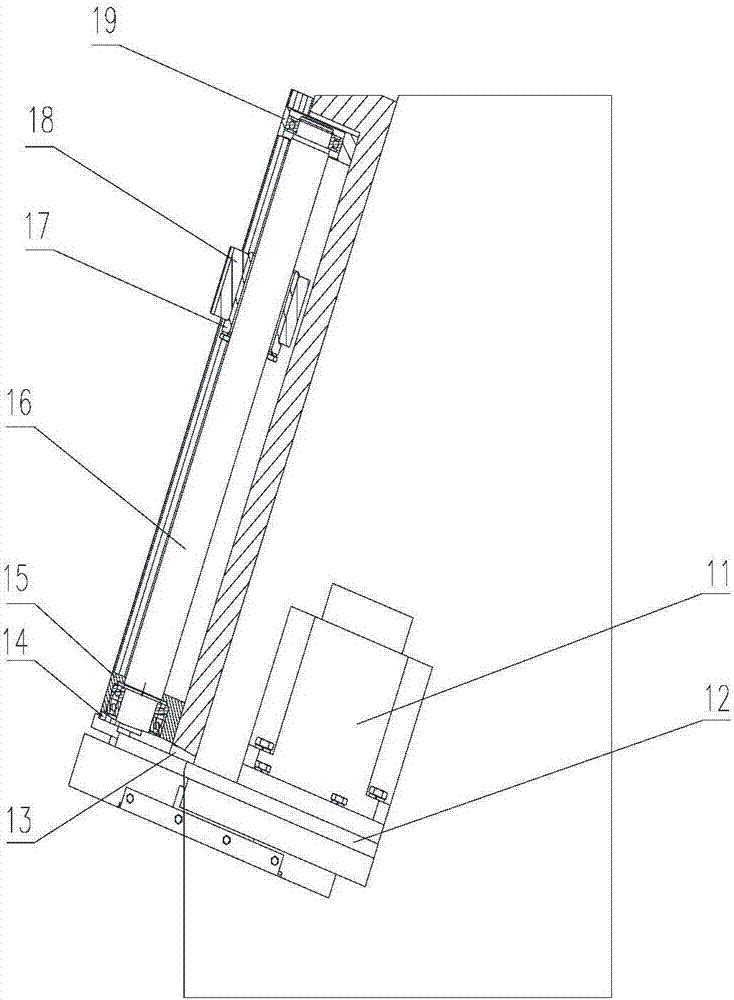

[0041] A clamping connection plate 30 is fixed on the reducer 21 with screws; a saw blade clamping part 31 is fixed on the clamping connection plate 30 with screws. The saw blade clamping parts 31 are symmetrically arranged on both sides of the saw blade, and each saw blade is provided with four saw blade clamping parts 31, and each of the saw blade clamping parts 31 is fixed on both sides of the corresponding saw blade A clamping block 32 is installed. The saw blade clamping part 31 ensures that the saw blade will not produce a large cross-sectional jump during the sawing process, ensures the sawing accuracy, and improves the sawing efficiency to a certain extent. Wherein, the material of the clamping block 32 adopts hard alloy with high hardne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com