Lifting rotary type billet feeding device

A rotary, casting billet technology, applied in the field of continuous casting billet hot transfer, can solve the problems of low red billet hot transfer rate, affecting production rhythm, unstable operation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

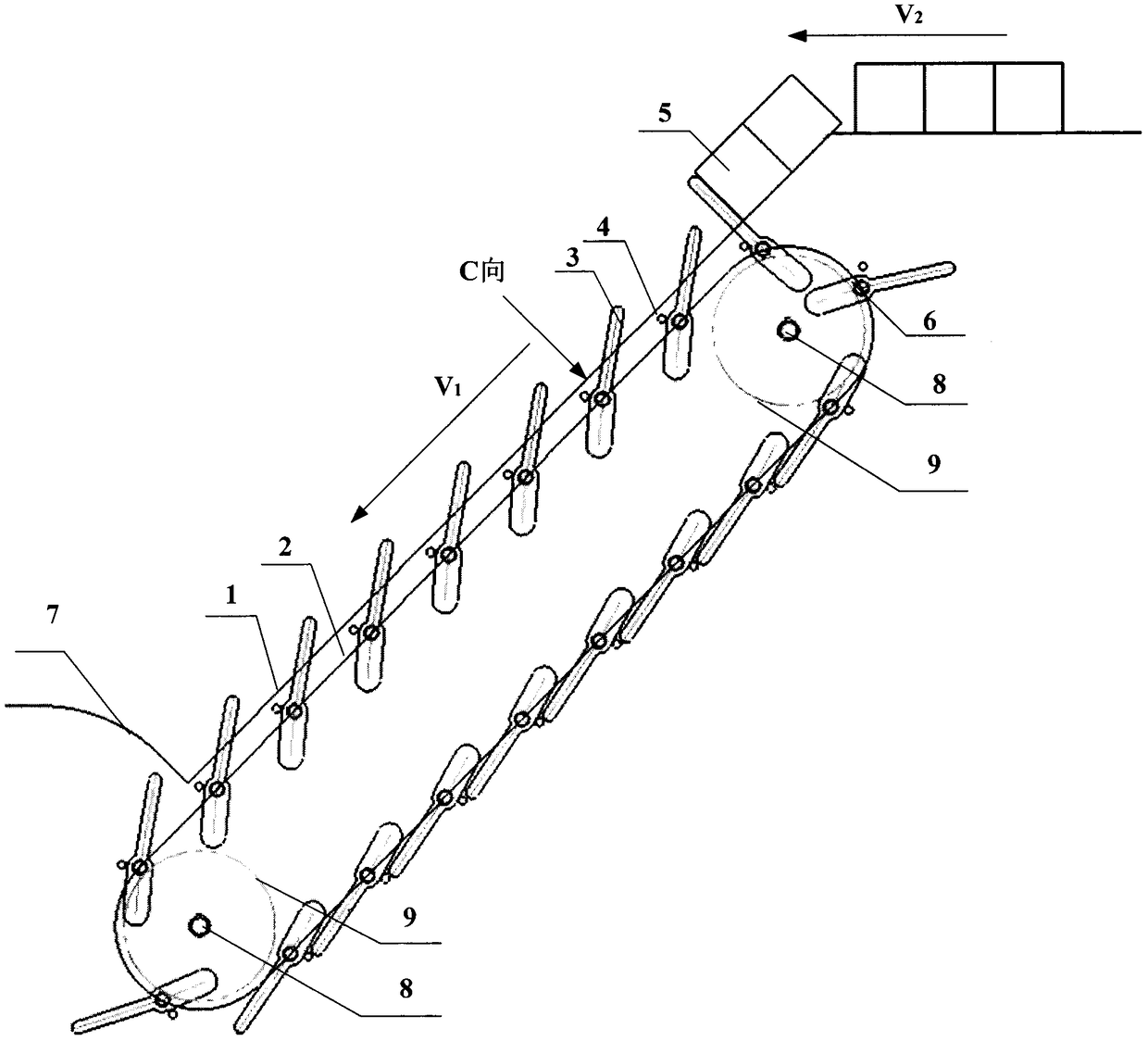

[0017] Example: such as figure 1 Shown is the process of casting slabs sliding down the inclined slide rail, and the embodiment takes pushing 5 slabs at a time as an example. Chain (2) speed V 1 Equal to the pushing speed V of the slab (5) 2 , when the first strand (5) slides to the nearest rotating baffle (3), and when the rotating baffle (3) is perpendicular to the inclined slide rail (1), the axis 1 (4) can limit the rotation of the rotating baffle (3) ) rotation. The back four billets (5) slide down to the inclined slide rail (1) continuously, and because the billets (5) are closely spaced, the rotating baffles (3) in the corresponding range are all pressed under the billets (5).

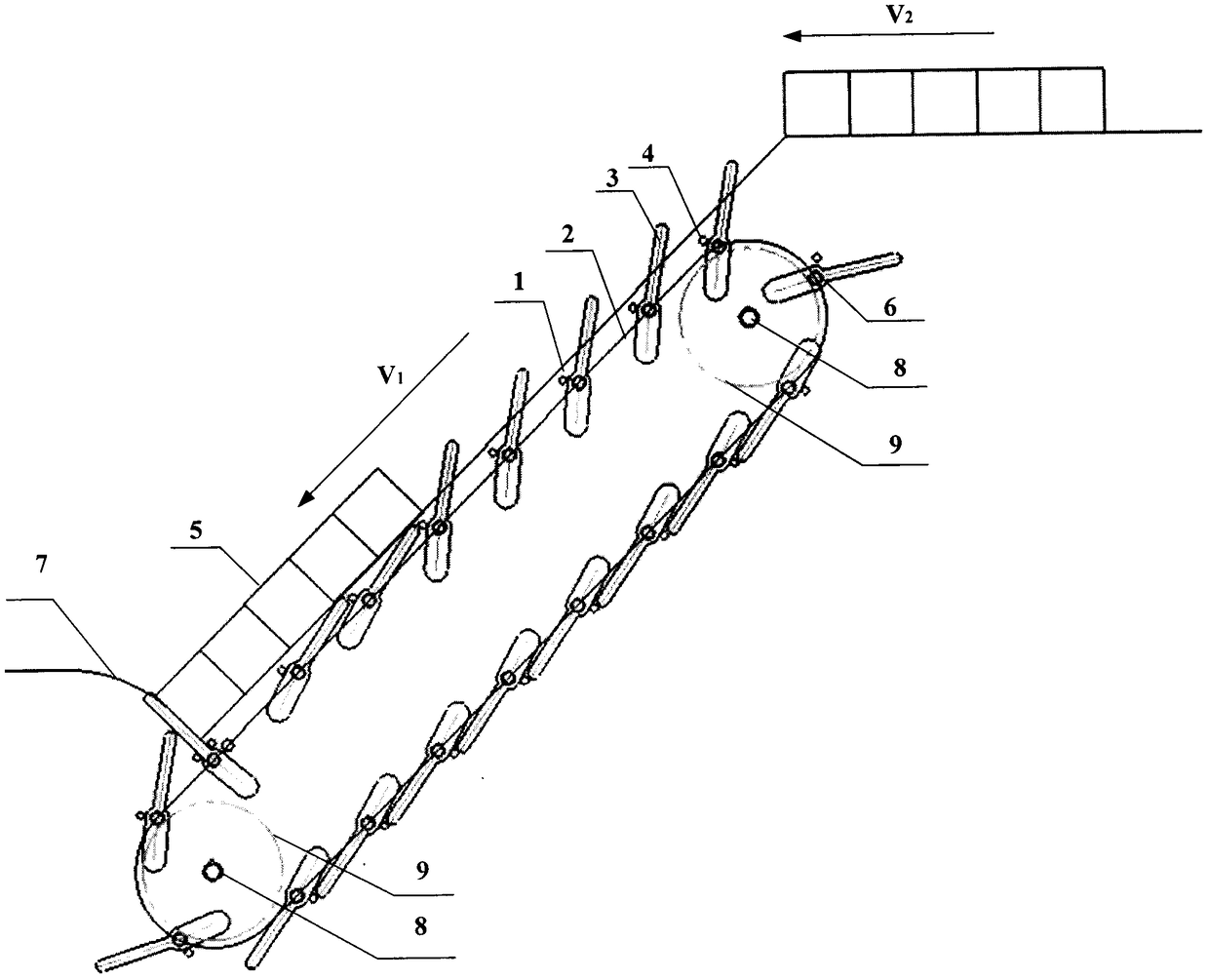

[0018] image 3 It is the process of transporting the billet to the fixed slide rail. The billet (5) arrives at the bottom and is jointly supported by the fixed slide rail (7) and the inclined slide rail (1), waiting for the next process to complete the transfer work of the billet (5). The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com