Contact tube positioning tool and contact tube machining method

A technology for positioning tooling and processing methods, applied in metal processing, metal processing equipment, conductors, etc., can solve the problems of difficulty in on-site debugging, affecting the power supply of the power grid, and unqualified three-phase products in the same period, so as to overcome the dependence of large-scale equipment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments of the present invention will be further described below in conjunction with the drawings.

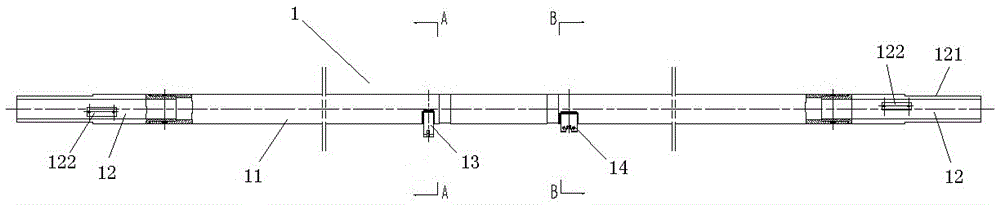

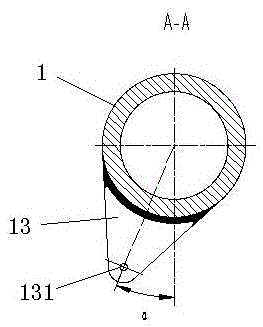

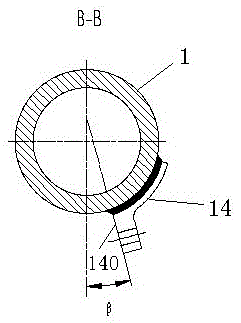

[0029] Specific embodiments of the conductive tube positioning tool of the present invention, such as Figure 4 to Figure 12 As shown, the conductive tube positioning tooling includes a workbench 2, on which a tooling positioning piece is installed. The tooling positioning piece includes an end positioning plate 8, a horizontal pressing plate 51, an intermediate pressing plate 52, a support positioning frame 3, a ball frame positioning frame 4 and V-block 7. The workbench 2 is provided with a T-shaped groove 21 extending in the left and right direction. The bottom of the support positioning frame 3, the ball rack positioning frame 4 and the V-shaped block 7 are all provided with a bump structure, and they are installed in the T-shaped block through the bump structure. Slot 21. End positioning plates 8 are fixed on the end surfaces of the left and right ends of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com