Automatic centering and clamping device for pipes

A technology of automatic centering and clamping device, applied in workpiece clamping device, positioning device, clamping and other directions, can solve the problems of low clamping efficiency, inaccurate positioning, scrapped pipe fittings, etc. Good heart effect, great effect of tightening force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing.

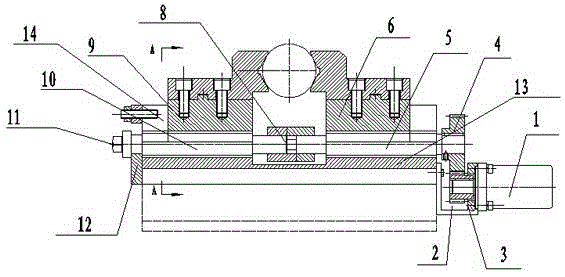

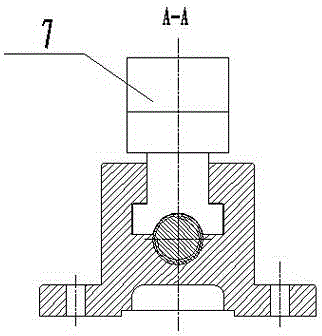

[0015] An automatic centering and clamping device for pipe fittings, which is provided with a base 13, and a right-handed screw 5 and a left-handed screw 10 are arranged in the base 13, and the left-handed and right-handed screw are fixedly connected by a plum blossom coupling. A right-handed sliding seat 6 is provided in the T-shaped groove of the base 13 above the bar 5, a left-handed sliding seat 9 is provided in the T-shaped of the base 13 above the left-handed screw 10, and a positioning plate 12 is provided at the left lower end of the base 13. The positioning plate 12 makes the left-hand screw 10 axially positioned, and the upper left of the base 13 is provided with a fixed plate 14, and the fixed plate 14 is provided with an adjusting screw 11 and a nut, and the adjusting screw 11 and the nut play a position-limiting role. , The right sliding seat is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com