Clutch hub demounting tool provided with handle sleeve and used for remanufacturing of automatic transmission

A technology for automatic transmissions and clutch hubs, applied in the manufacture of tools, hand-held tools, etc., can solve the problems of clutch hub damage, loud noise, inconvenience, etc., and achieve the effect of not easy noise, low noise, and good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

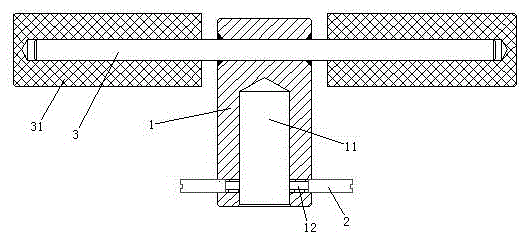

[0024] Embodiment one, see figure 1 , a clutch hub removal tool provided with a handle glove for remanufacturing an automatic transmission, including a pull rod 1 . The upper end of the pull rod 1 is provided with a grip rod 3 . Grip bar 3 has two. Two holding rods 3 are symmetrically distributed on both sides of the pull rod 1 . 3 sets of grip bars are provided with handle gloves 31 . The handle glove 31 is a rubber sheath. The handle glove 31 is detachably sheathed on the handle bar 3 . The end surface of the lower end of the pull rod 1 is provided with an accommodating hole 11 which can be sleeved on the rotating shaft. The wall of the receiving hole 11 is provided with a through hole 12 that can be aligned with the slot when the rotating shaft is inserted into the receiving hole. The through hole 12 is a threaded hole. A bayonet pin 2 that can be inserted into the bayonet is screwed into the through hole 12 . Bayonet 2 is a jacking bolt.

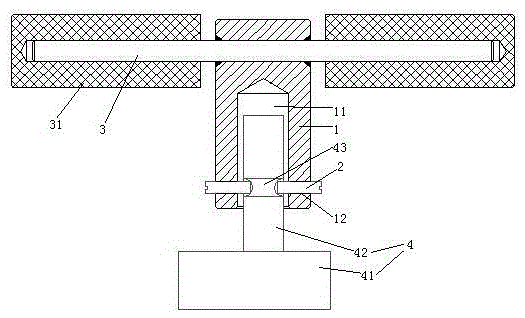

[0025] see figure 2 Th...

Embodiment 2

[0027] Embodiment two, the difference with embodiment one is:

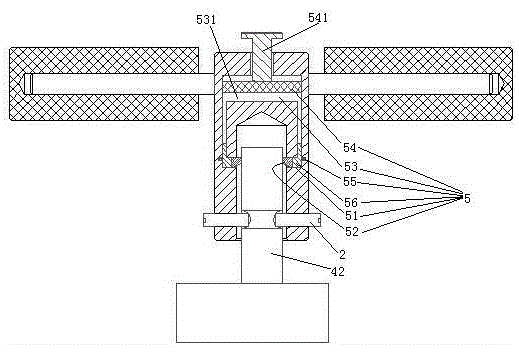

[0028] see image 3 , a clamping and fixing structure 5 is also provided. The clamping and fixing structure 5 includes a sliding hole 51 , a clamping block 52 slidingly and sealingly connected to the sliding hole, a piston chamber 53 , a pressurizing piston 54 slidingly and sealingly connected to the piston chamber, and a heating mechanism 55 . The sliding hole 51 is disposed on a wall of the receiving hole 11 . There are two sliding holes 51 . Two sliding holes 13 are distributed along the circumferential direction of the tie rod 1 . The piston chamber 53 is disposed on the tie rod 1 . There is only one piston chamber 53. The piston chamber 53 is in communication with all the slide holes 51 . The press piston 54 is provided with a press rod 541 . The pressing rod 541 protrudes from the end of the tie rod 1 . A closed cavity 531 is formed between the pressurizing piston 54 and the clamping block 52 . A ti...

Embodiment 3

[0031] Embodiment three, the difference with embodiment two is:

[0032] see Figure 4, An elastic force adjustment mechanism 8 is provided between the grip bar 3 and the handle cover 31 . The elastic force adjustment mechanism 8 includes a base pipe 81 , a clamping layer 82 and a preload adjustment structure 83 . The base tube 81 is sheathed outside the handle bar 3 . The base pipe 81 is passed through the handle glove 31 . The clamping layer 82 is composed of several friction strips 821 . The friction strips 821 are distributed along the circumferential direction of the base pipe 81 . The friction strip 821 is provided with a plurality of slide bars 822 axially distributed along the radial extension of the base pipe. The sliding rod 822 slides through the base tube 81 . The inner end of the sliding rod 822 is provided with a third spring 823 . The third spring 823 drives the friction strip to abut against the handle glove 31 through the slide bar. The outwardly movin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com