High-speed casting film production equipment

A technology of production equipment and cast film, applied in the field of high-speed cast film production equipment, can solve the problems of unreasonable arrangement, low production efficiency, low degree of automation of cast film production line, etc., so as to improve production efficiency and efficiently recover edge material. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

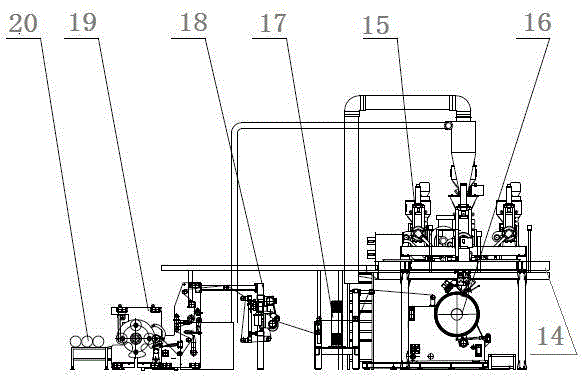

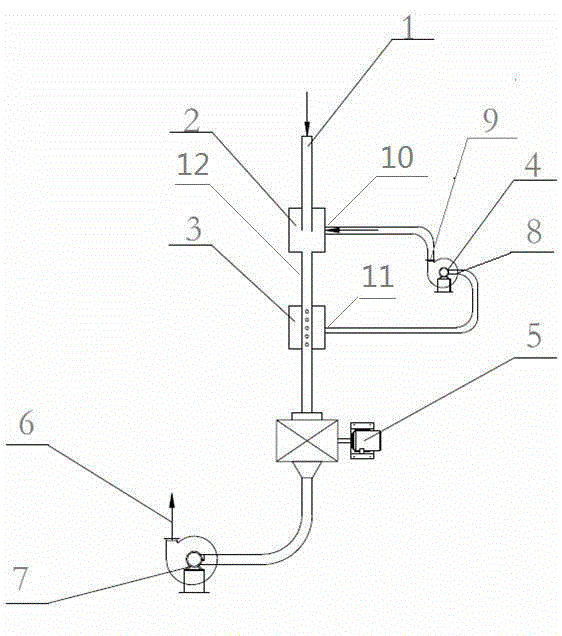

[0025] Such as figure 1 and figure 2 As shown, a high-speed cast film production equipment, the frame 14 is provided with an extrusion system 15, and below the extrusion system 15, a cast system 16, a thickness measurement system 17, a traction pendulum system 18 and Rewinding system 19, described extruding system 15 has included the edge material recovery system, and described edge material recovery system comprises lead edge material pipeline 1, the suction device that is connected with lead edge material pipeline and the crusher that is connected with suction device 5. The suction device includes a negative pressure suction box 2, an exhaust box 3 and a negative pressure suction fan 4, the suction port of the negative pressure suction fan 4 is connected to the exhaust box 3, and the negative pressure suction fan 4 The air outlet of the suction fan 4 is connected with the negative pressure suction box 2, and the negative pressure suction box 2 is connected with the exhaust...

Embodiment 2

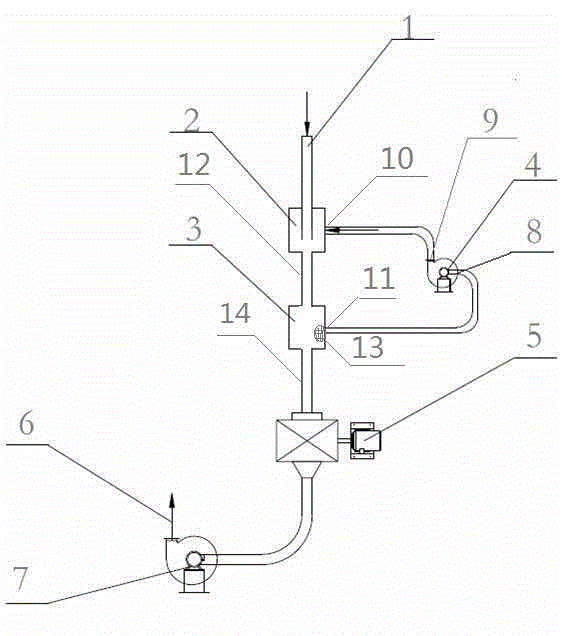

[0033] Such as figure 1 and image 3 As shown, a high-speed cast film production equipment includes a frame 14, and the frame 14 is sequentially provided with an extrusion system 15, a casting system 16, a thickness measuring system 17, a traction system 18 and a winding system 19, Described extruding system 15 has included the side material recycling system, and described side material recovery system comprises leading side material pipeline 1, the suction device that is connected with leading side material pipeline and the crusher 5 that is connected with suction device, described suction The feeding device comprises a negative pressure suction box 2, an exhaust box 3 and a negative pressure suction fan 4, the suction port of the negative pressure suction fan 4 is connected with the exhaust box 3, and the outlet of the negative pressure suction fan 4 The tuyere is connected to the negative pressure suction box 2, which is sequentially connected to the exhaust box 3 and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com