Printing device

A printing device and printing platform technology, applied in the direction of printing device, printing, etc., can solve the problems of increasing coverage times, reducing inkjet volume, low efficiency, etc., achieving the effect of effective implementation of functions, increasing printing costs, and reducing research and development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

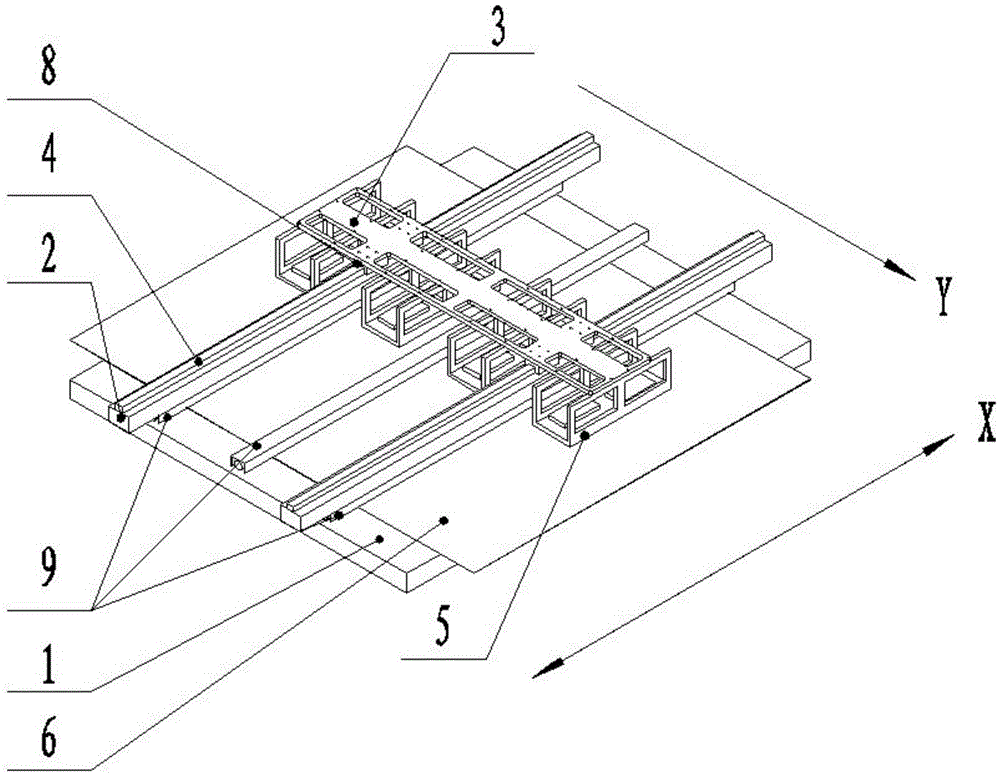

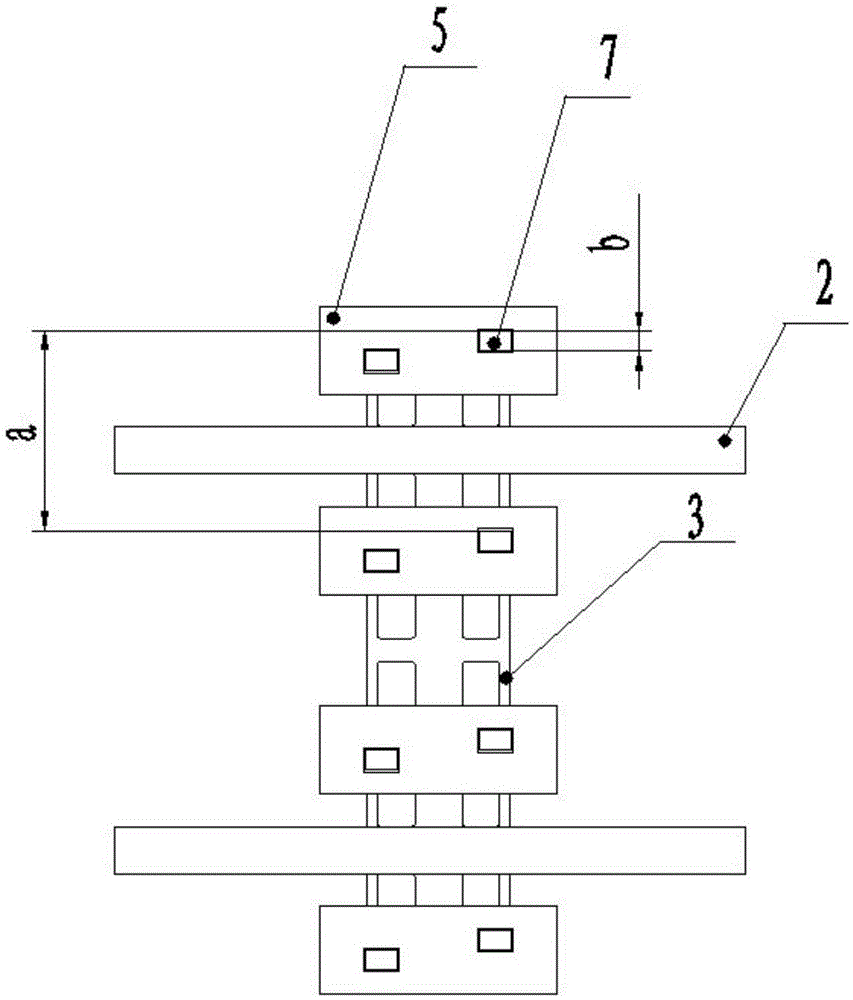

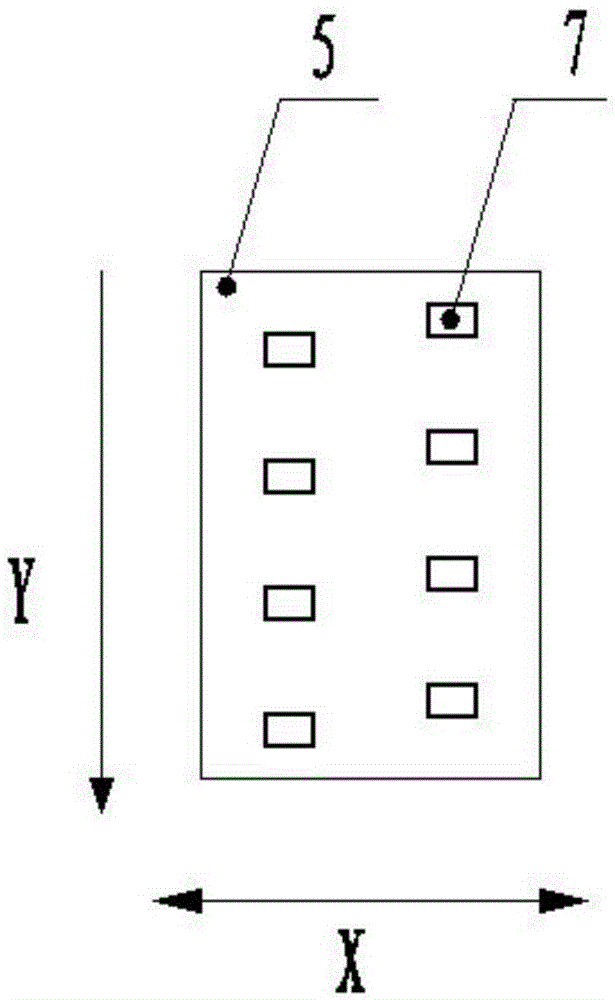

[0025] Such as figure 1 As shown, a printing device includes a printing platform 1, and a plurality of parallel beams 2 are horizontally arranged above the printing platform 1, and a guide rail 4 is provided on each of the beams 2. A slide table 3 arranged longitudinally is provided on the beam 2, and the slide table 3 is slidably connected to the guide rail 4 and can reciprocate back and forth along the beam 2. Preferably, the slide table 3 is arranged on the slide The slide block 8 at the bottom of the table 3 moves back and forth on the guide rail 4 . A plurality of nozzles 5 are installed on the slide table 3 , and in actual production, the content to be printed by each group of nozzles 5 can be specified accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com