Universal rotary ballpoint pen provided with two layers of ballpoint hole plates

A bead-hole plate and ballpoint pen technology, applied in ballpoint pens, nibs, printing, etc., can solve the problems of non-compliance with the development requirements of an environmentally friendly and low-carbon society, "ball bead" falling off, waste of resources, etc., and achieve smooth and smooth writing, Reasonable structure, easy to carry and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing:

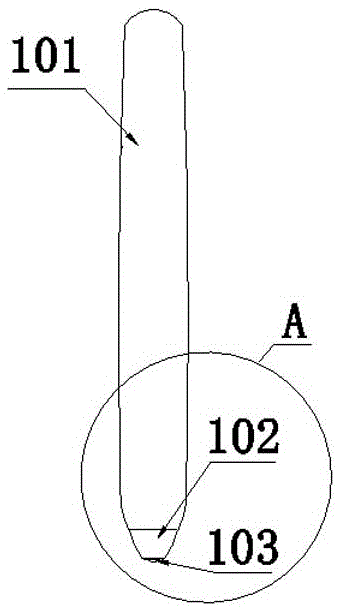

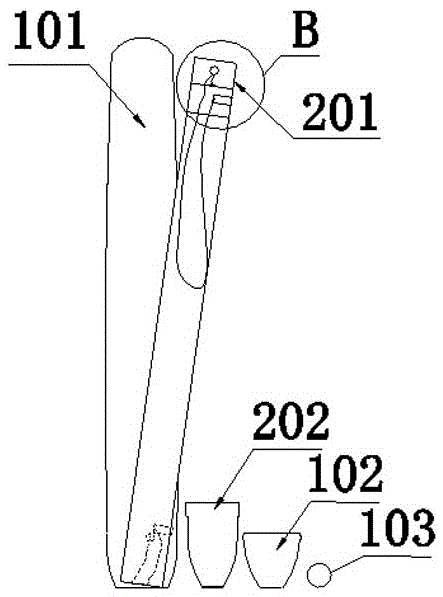

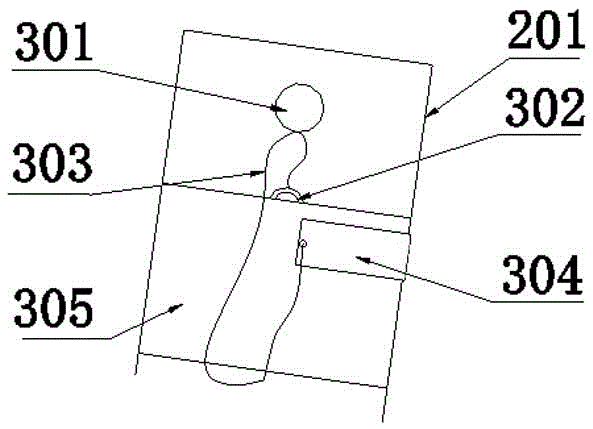

[0020] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 As shown, the present invention is a double-layer bead hole plate universal ball pen, comprising a hollow pen holder 101, a functional sleeve assembly 202, an elastic bead hole plate a410, an elastic bead hole plate b414, and a writing ball 103, and is characterized in that: The internal thread connection port of the hollow pen holder 101 is movably connected with the functional sleeve assembly 202, and four spring pieces 402, the shield connection slot 406 are movably connected with the elastic movable shield 102; the hollow pen holder 101 is built with piston ink Tube 201; the lower end of the piston ink-absorbing tube 201 is movably plugged into the ink pipe connection socket 407 provided by the functional sleeve assembly 202; the bottom of the ink pipe conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com