Stand-by emergency braking device for truck

An emergency braking and truck technology, applied in the direction of brakes, braking components, vehicle components, etc., can solve problems such as brake function failure, brake pump oil leakage, gas storage tank or pipeline interface leakage, etc., to achieve consistent driving force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

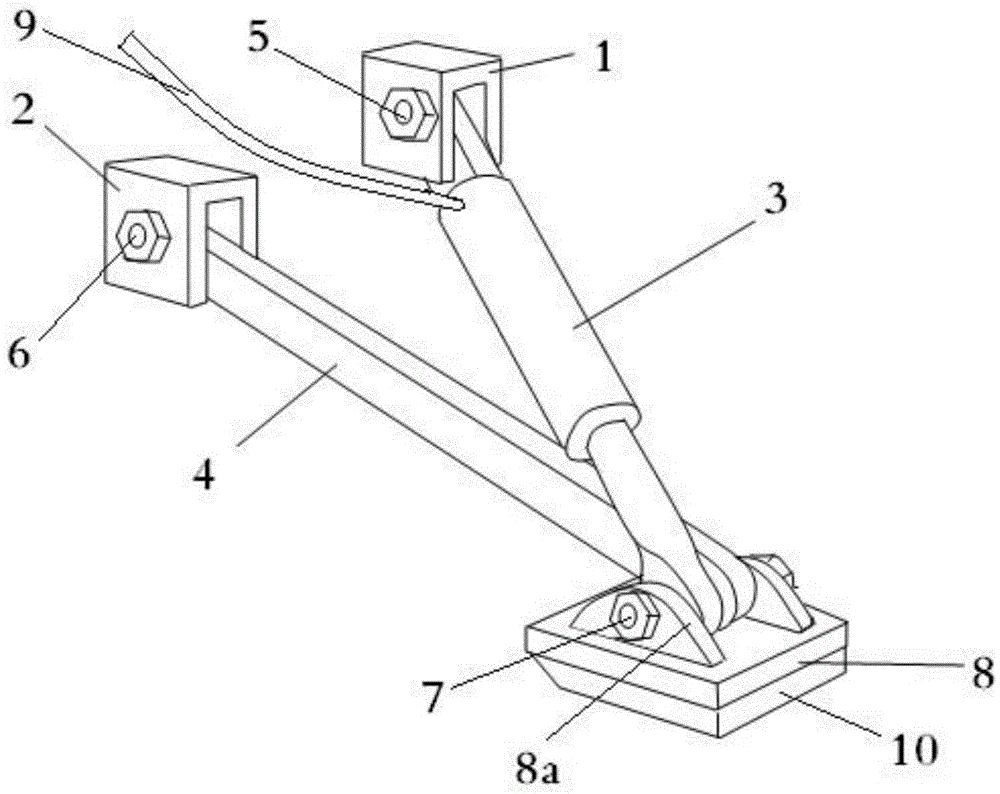

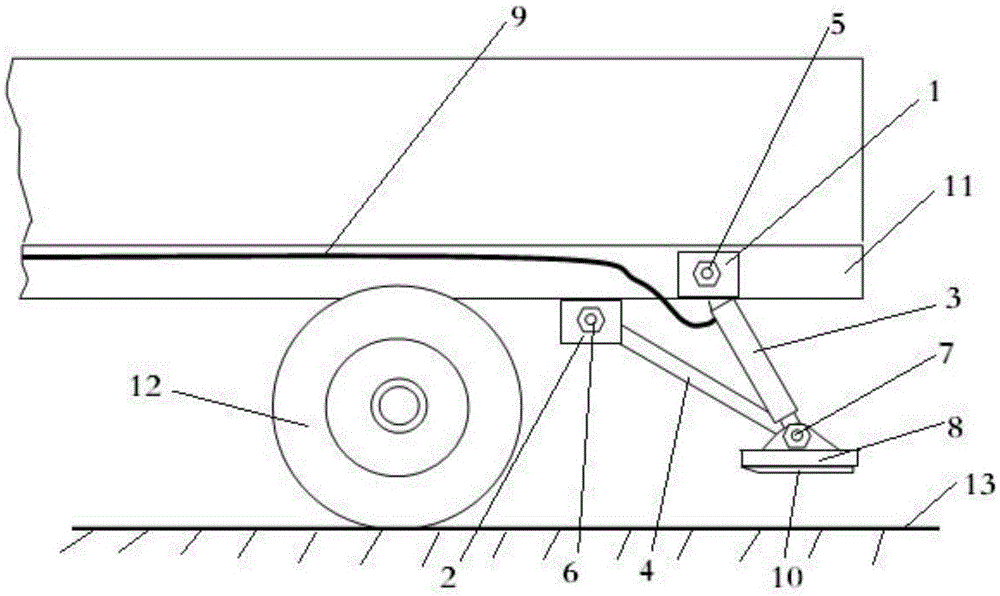

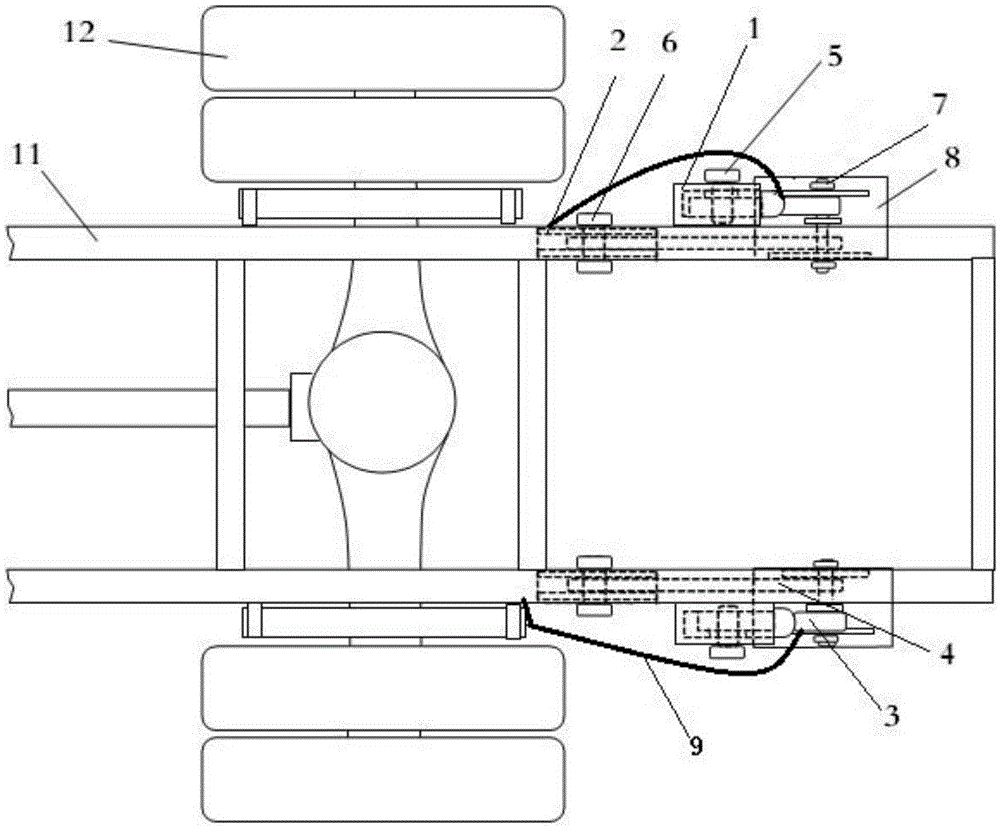

[0014] like figure 1 The shown truck emergency braking device includes a piston cylinder seat 1 and a tie rod seat 2, a piston cylinder 3 with a piston rod whose upper end is connected to the piston cylinder seat, a tie rod 4 whose upper end is connected to the tie rod seat, and the lower end of the piston rod and The lower end of the pull rod is connected to the flat friction brake plate 8 at the same time; the piston cylinder and the piston cylinder seat are connected by the first connecting bolt 5, and the upper end sleeve hole of the piston cylinder is freely set on the screw rod of the first connecting bolt, and the piston cylinder can be connected by the first connecting bolt. A screw rod connecting the bolt is free to rotate for the hinge shaft. The pull rod and the pull rod seat are connected by the second connecting bolt 6, and the upper end sleeve hole of the pull rod is freely sleeved on the screw rod of the second connecting bolt, and the pull rod can be freely rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com