Installation device and installation method for runner paddles of axial flow paddle turbine

A hydraulic turbine and paddle technology is applied in the field of installation devices for the runner blades of an axial-flow rotary paddle turbine, which can solve the problems of unstable walking of bridge cranes, damage to bolts and screw holes, and achieve simple structure, convenient operation, Uniform force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

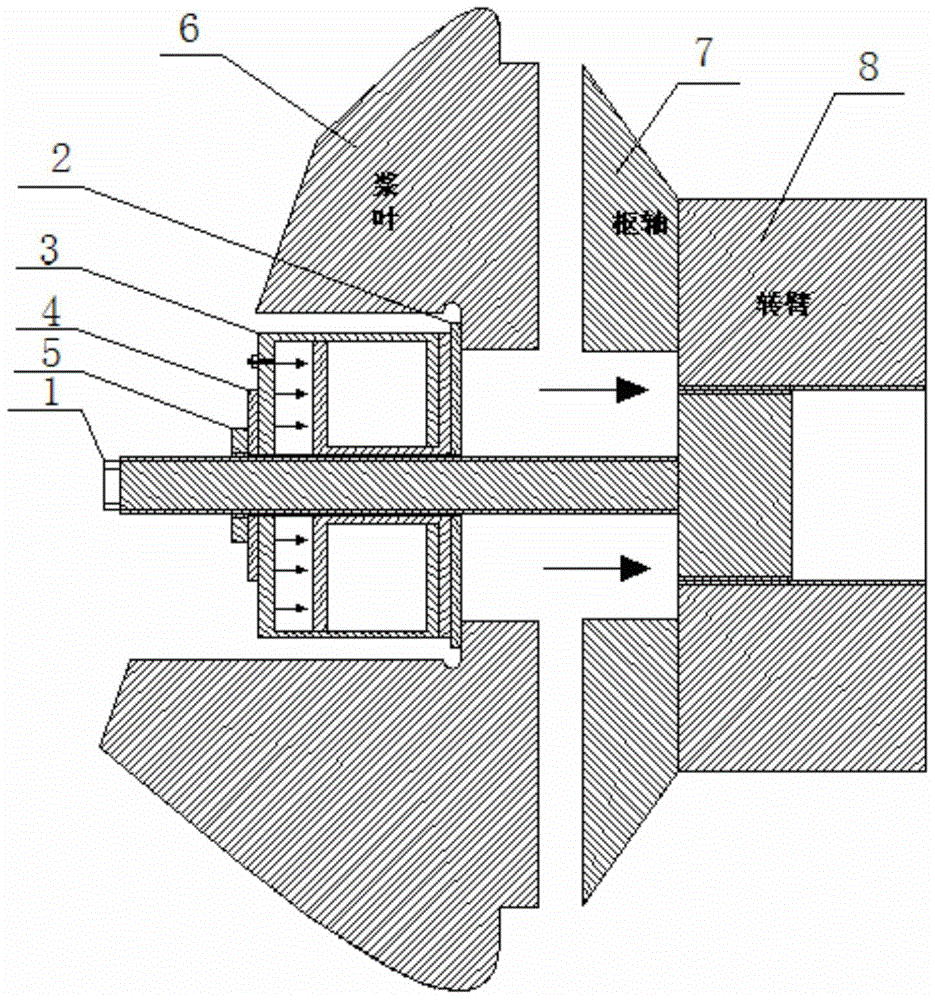

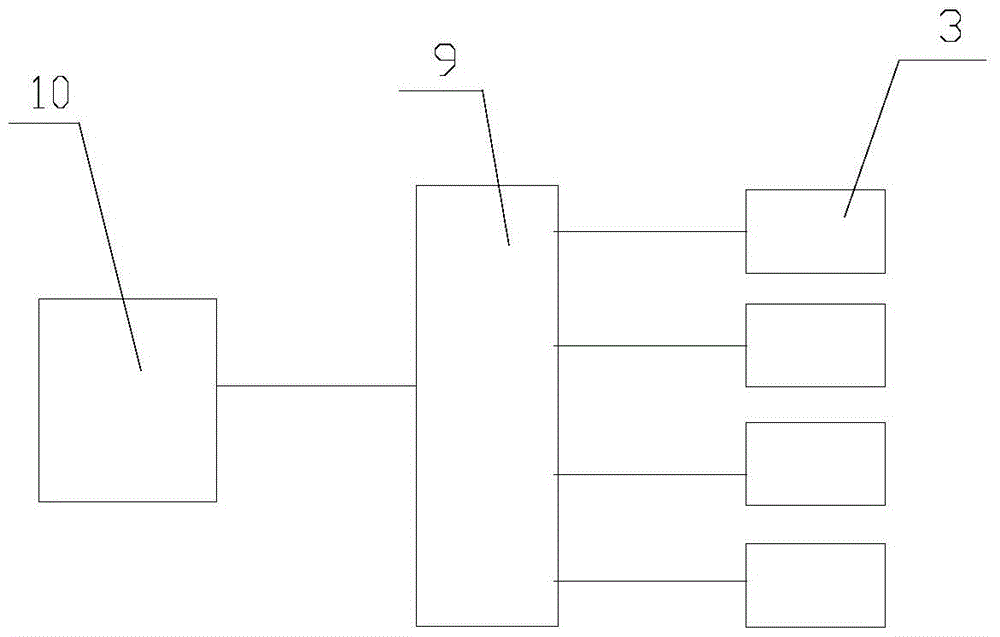

[0020] Such as figure 1 As shown, the device of the present invention consists of four threaded support rods 1, four inner washers 2, four hollow hydraulic jacks 3, four outer washers 4, four nuts 5, one oil separator 6, one electric Pressure pump 7 and four high-pressure hoses constitute. Four threaded support rods 1 are threadedly connected to the screw holes of the rotating arm 8 respectively, and are evenly and symmetrically distributed. Each support rod is socketed with an inner gasket 2, and then socketed with a hollow hydraulic jack 3, and then socketed with another Outer washer 4, and finally screw nut 5 into support rod 1 and tighten, so that inner washer 2 is closely attached to the flange of the bolt hole of blade 6, the hollow hydraulic jack is attached to inner washer 2, and outer washer 4 is attached to the hollow On the hydraulic jack; the four hollow hydraulic jacks 3 are respectively connected to the oil separator 9 through high-pressure hoses, and the oil se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com